Mounting assembly for a heat exchanger device

A technology of heat exchange device and assembly, applied in the direction of heat exchange equipment, heat exchanger type, heat exchanger shell, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

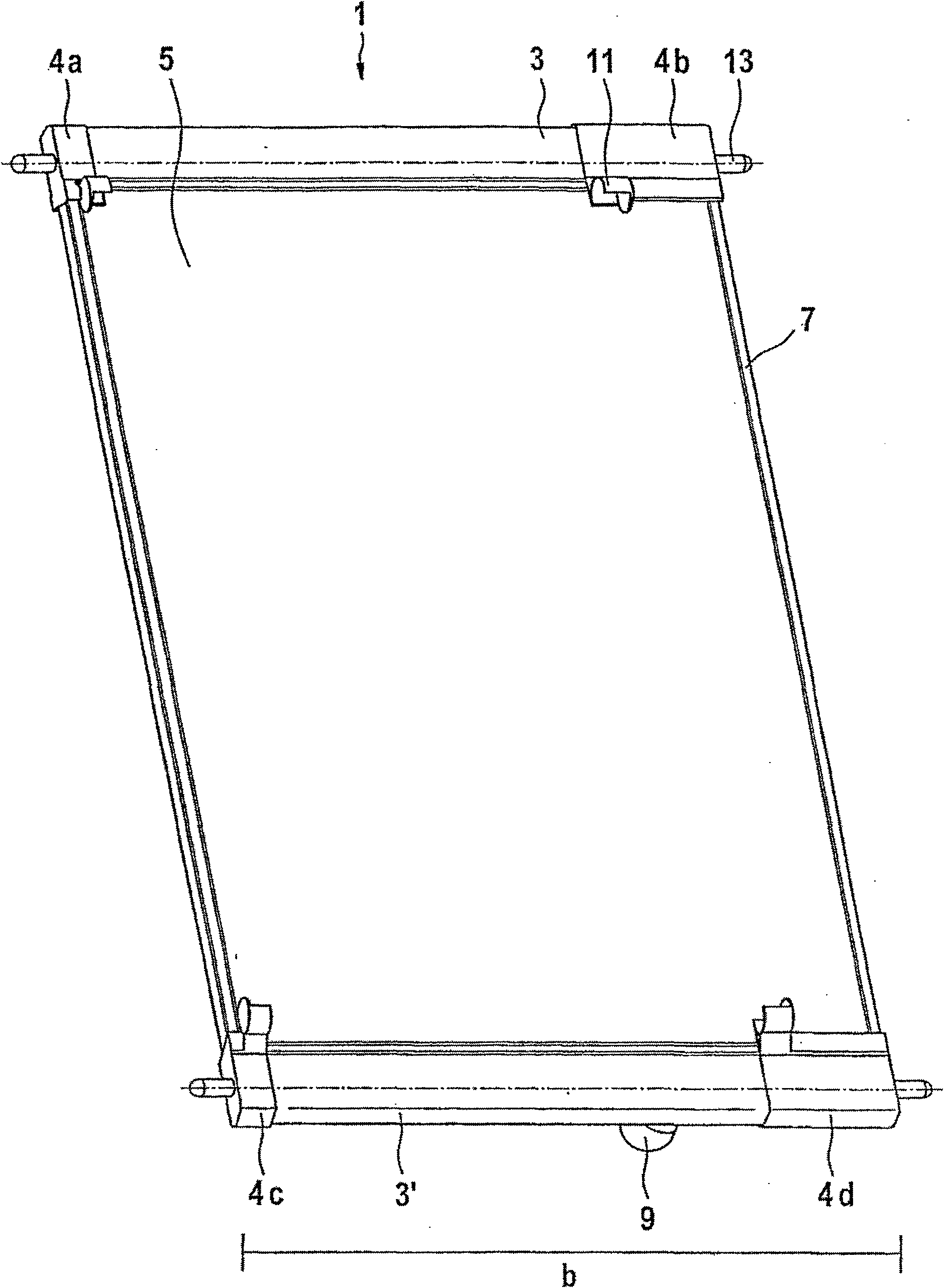

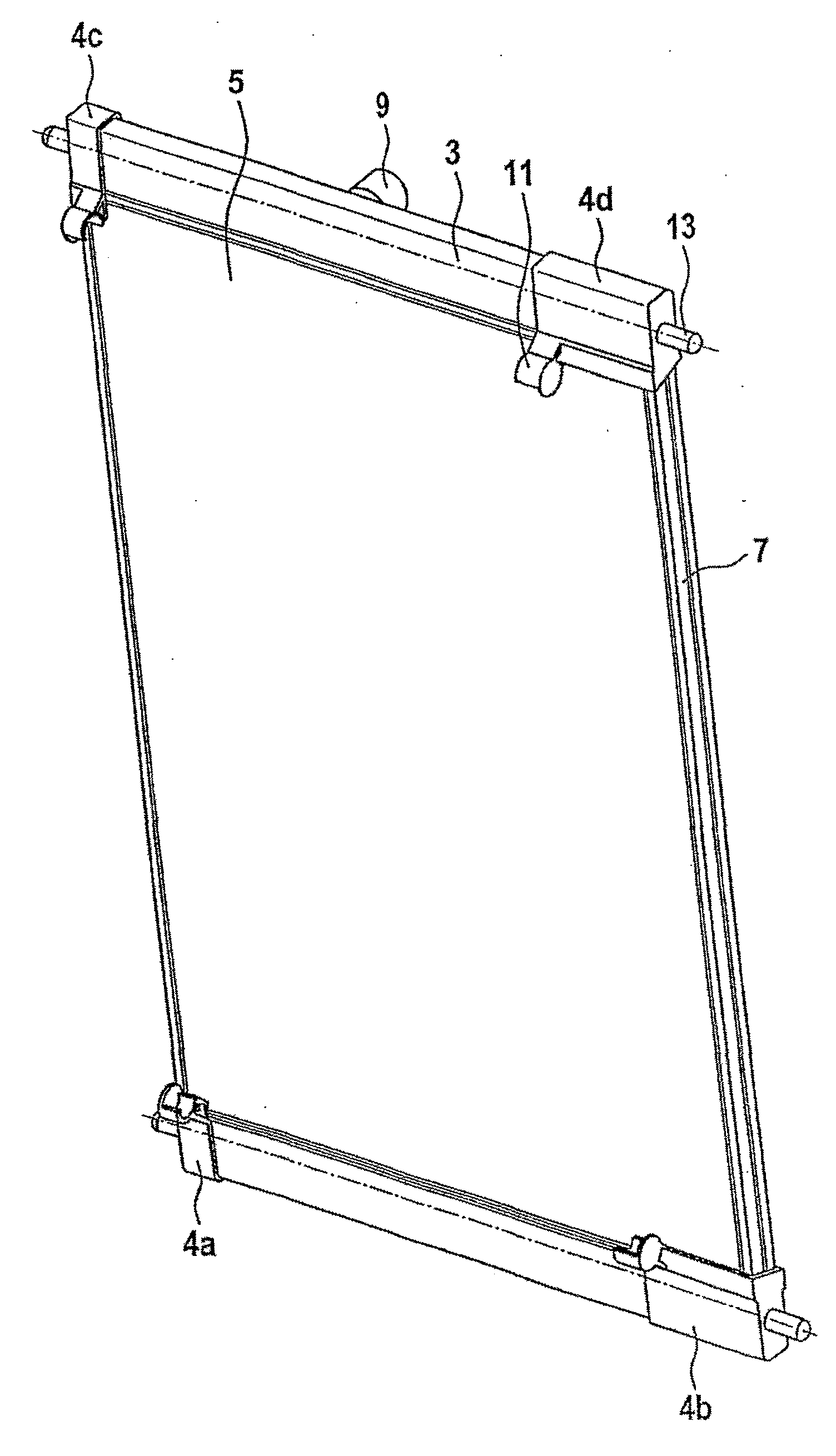

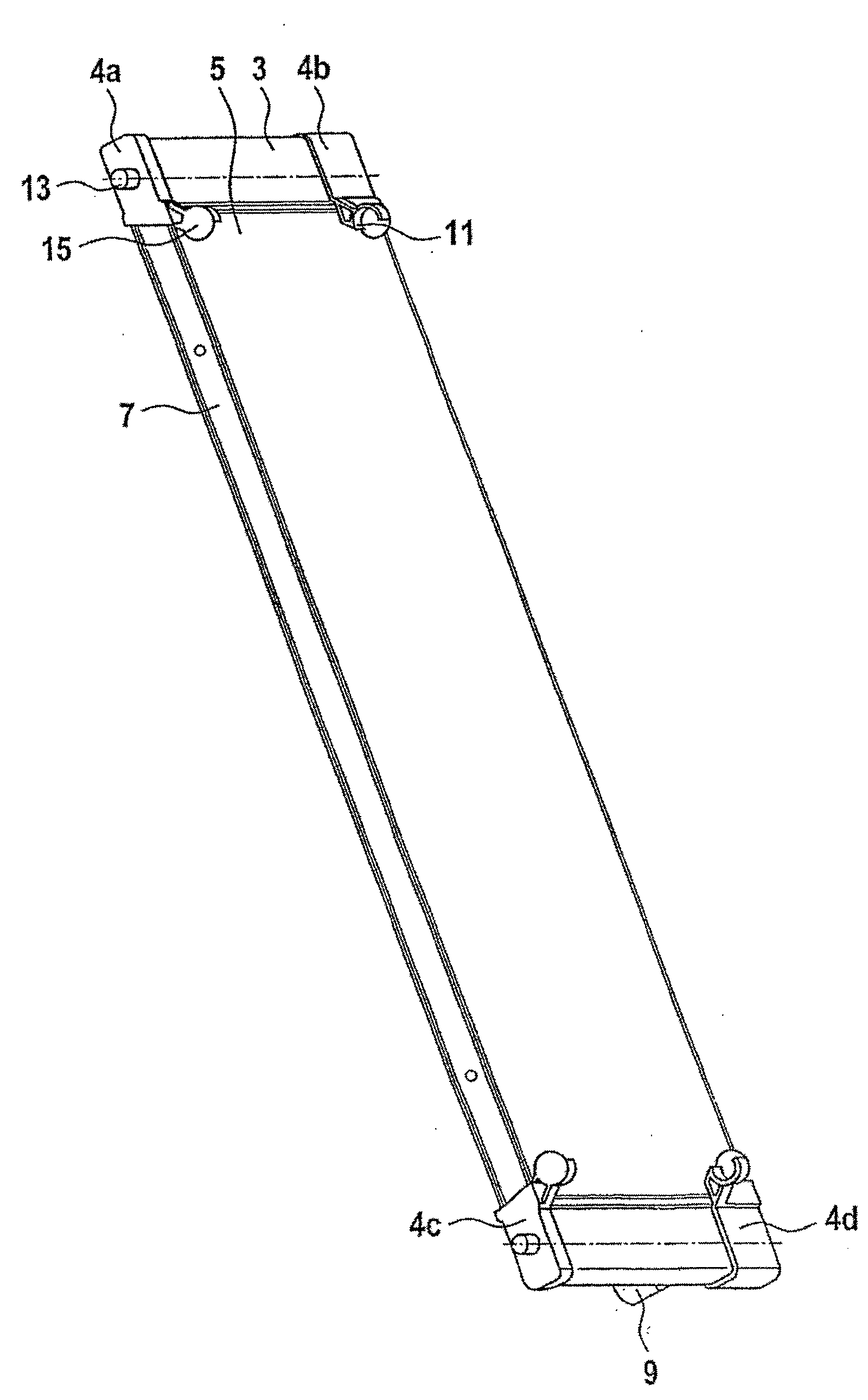

[0064] figure 1 It is a perspective view of the assembly assembly 1 according to the present invention. In the figures, reference numeral 3 refers to a first header and / or distribution pipe, and reference numeral 3' refers to a second header and / or distribution pipe. Reference numeral 5 indicates the area occupied by the arrangement of various piping components (not shown in the figure). Here, the line elements are arranged along the width b. Reference numerals 4a, 4b, 4c and 4d refer to the mounting elements in the upper left corner, upper right corner, lower left corner and lower right corner in turn. In this embodiment, the mounting elements have projections 13 which protrude laterally out of the device 1 in the direction b. Reference numeral 11 denotes a positioning element of another device (not shown) through which fluid flows or receives fluid. Reference numeral 7 denotes a frame member.

[0065] figure 2 for figure 1 Another perspective view of the assembly sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com