Self-sealing manhole cover for bulk loading powder tank truck

A self-sealing and manhole cover technology, applied in underwater structures, buildings, infrastructure engineering, etc., can solve the problems of no adhesion, discharge, and easy wrinkling of rubber rings, etc., to achieve good sealing effect and ensure sealing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The self-sealing manhole cover for bulk powder tank truck of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments:

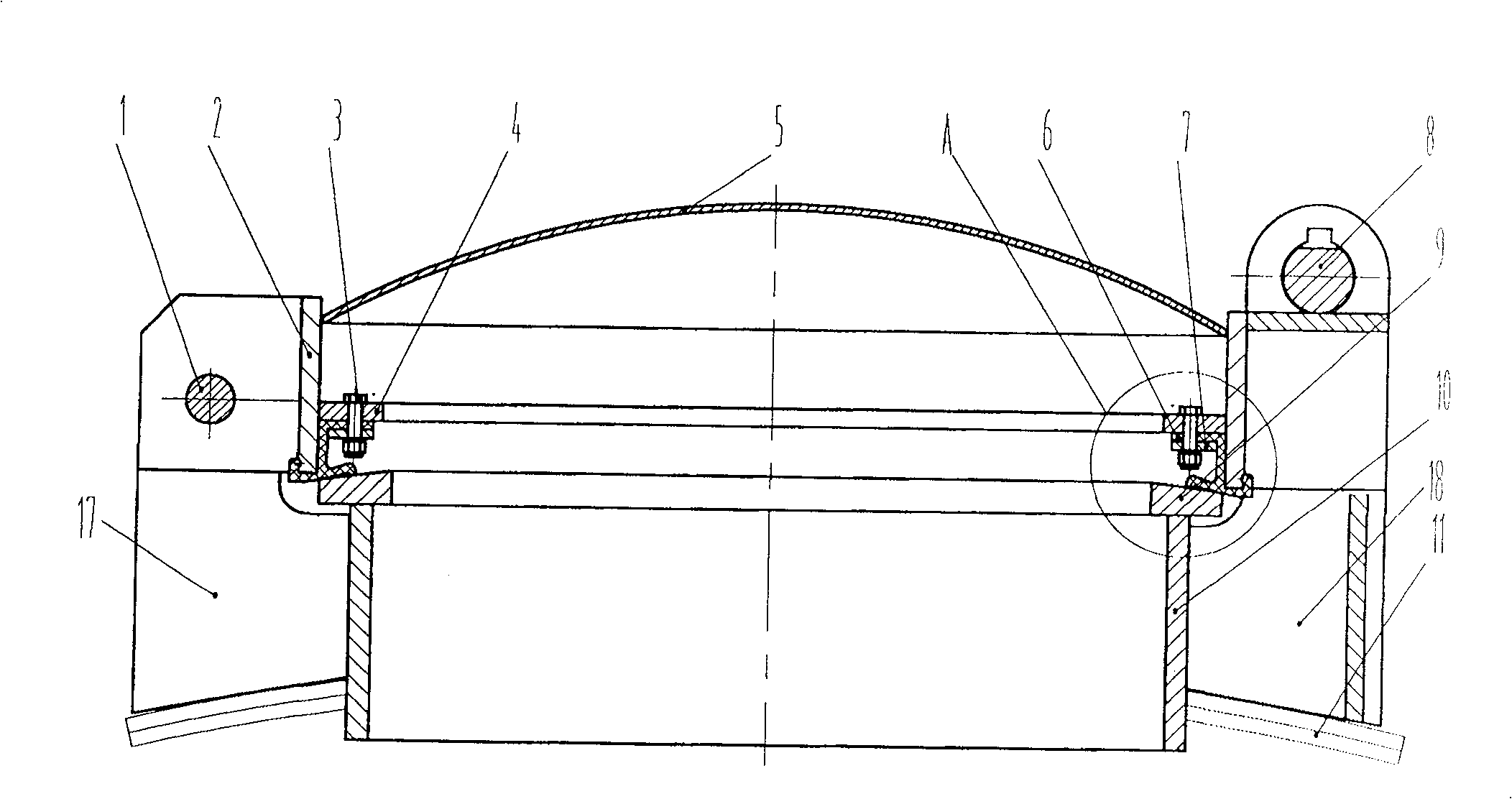

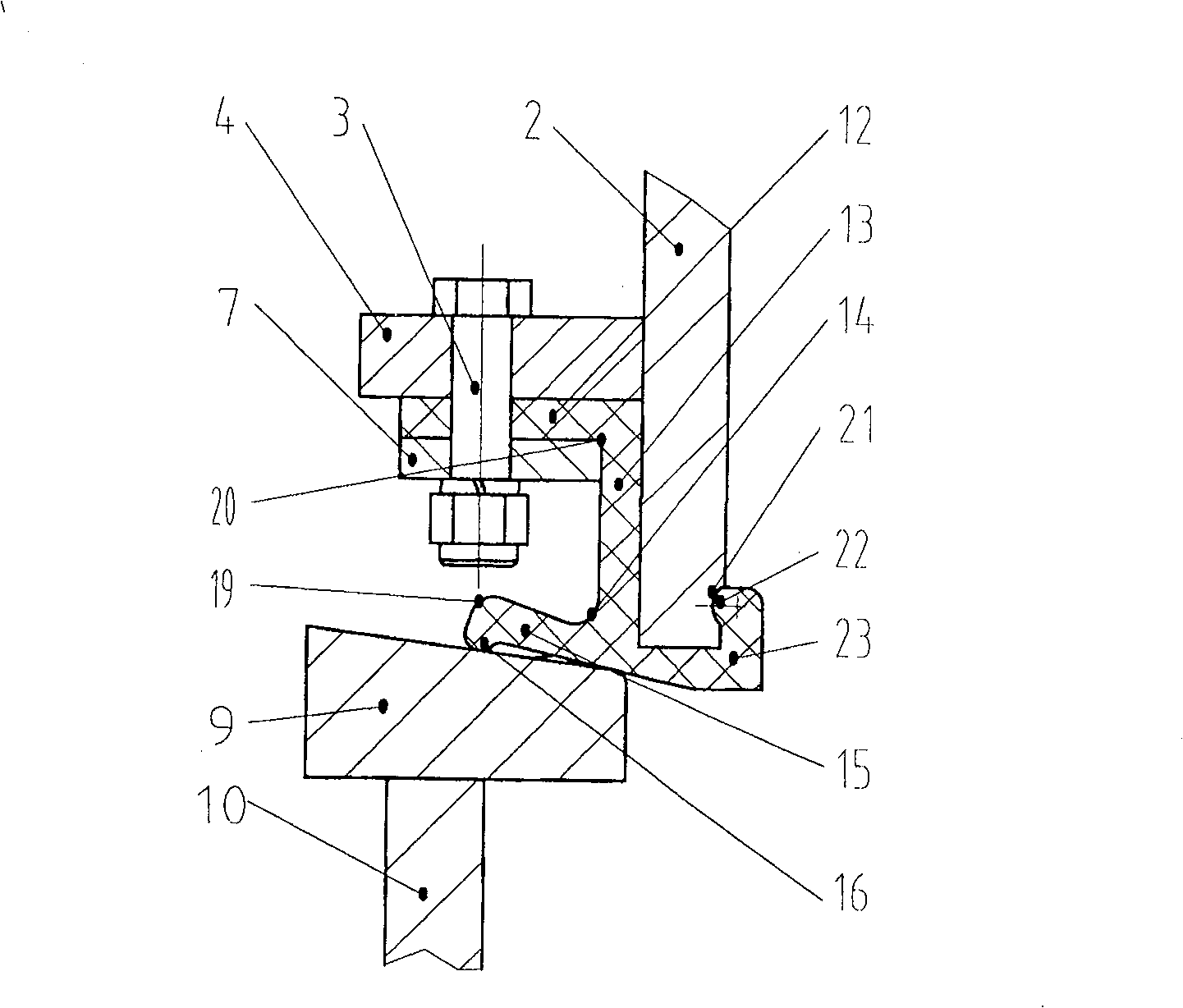

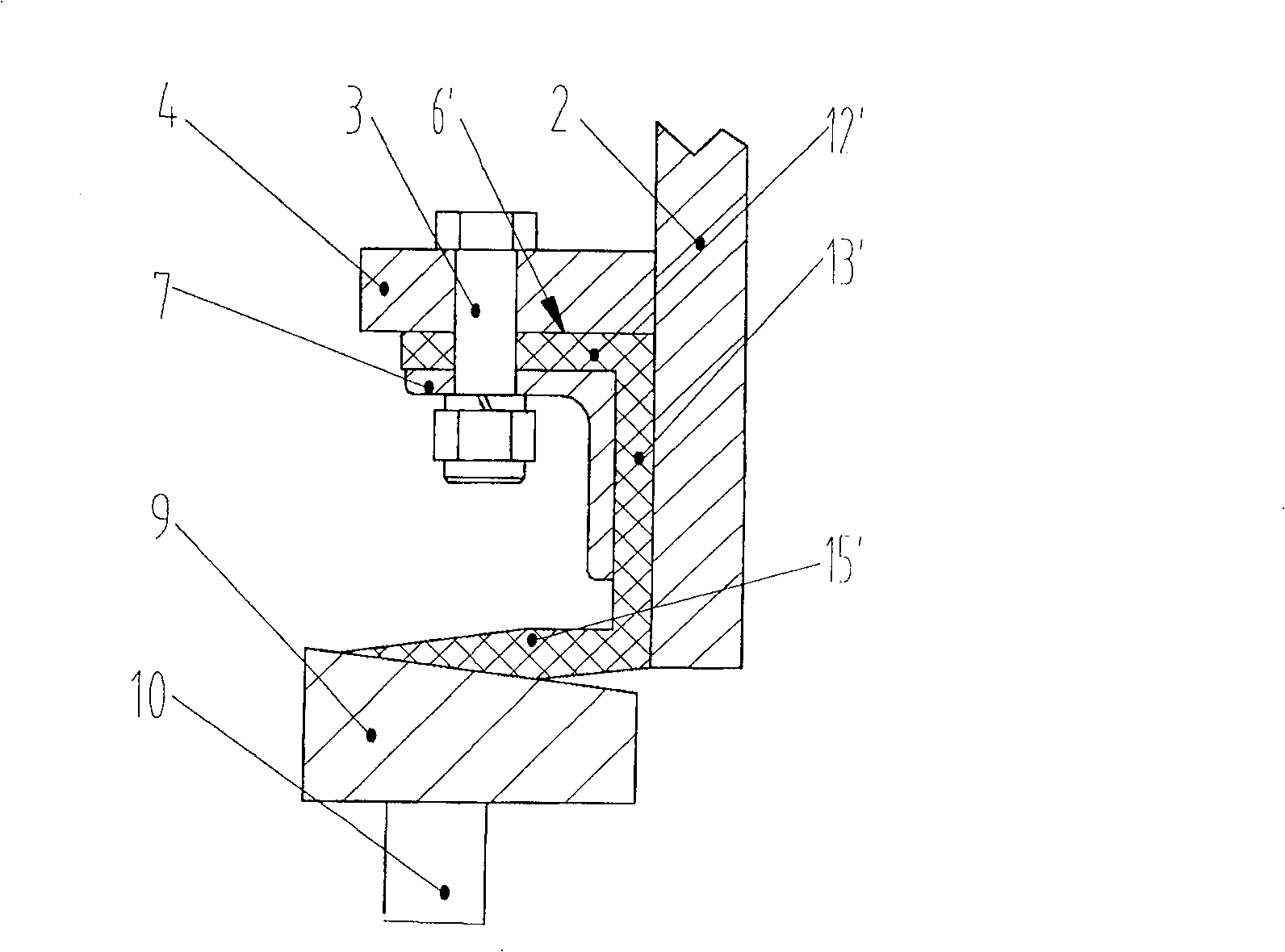

[0026] Such as figure 1 Shown, the self-sealing type manhole of bulk powder tanker mainly is made up of two parts of manhole seat and manhole cover of the present invention. The manhole seat is assembled and welded by the manhole seat ring 10, the cover ring 9, the repin support plate 17 and the revolving lock support plate 18, and is welded and fixed on the tank body 11. The manhole cover is composed of a manhole cover ring 2, a top cover 5, a fixed pressure plate 4, a pressure ring 7 and a rubber ring 6, etc. The pressure ring 7 adopts a flat flange type pressure ring, and the fixed pressure plate 4 can It is widened and thickened by 1-3mm, and its installation position can also be moved up and down by 8-10mm on the basis of the traditional size. The manhole cover ring 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com