Minsize pick-up lens

A lens and miniature technology, which is applied in the field of imaging lens, can solve the problems of design, processing and fixing difficulties, and the complex structure of free-form prisms, etc., and achieve the effect of light weight, small size and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

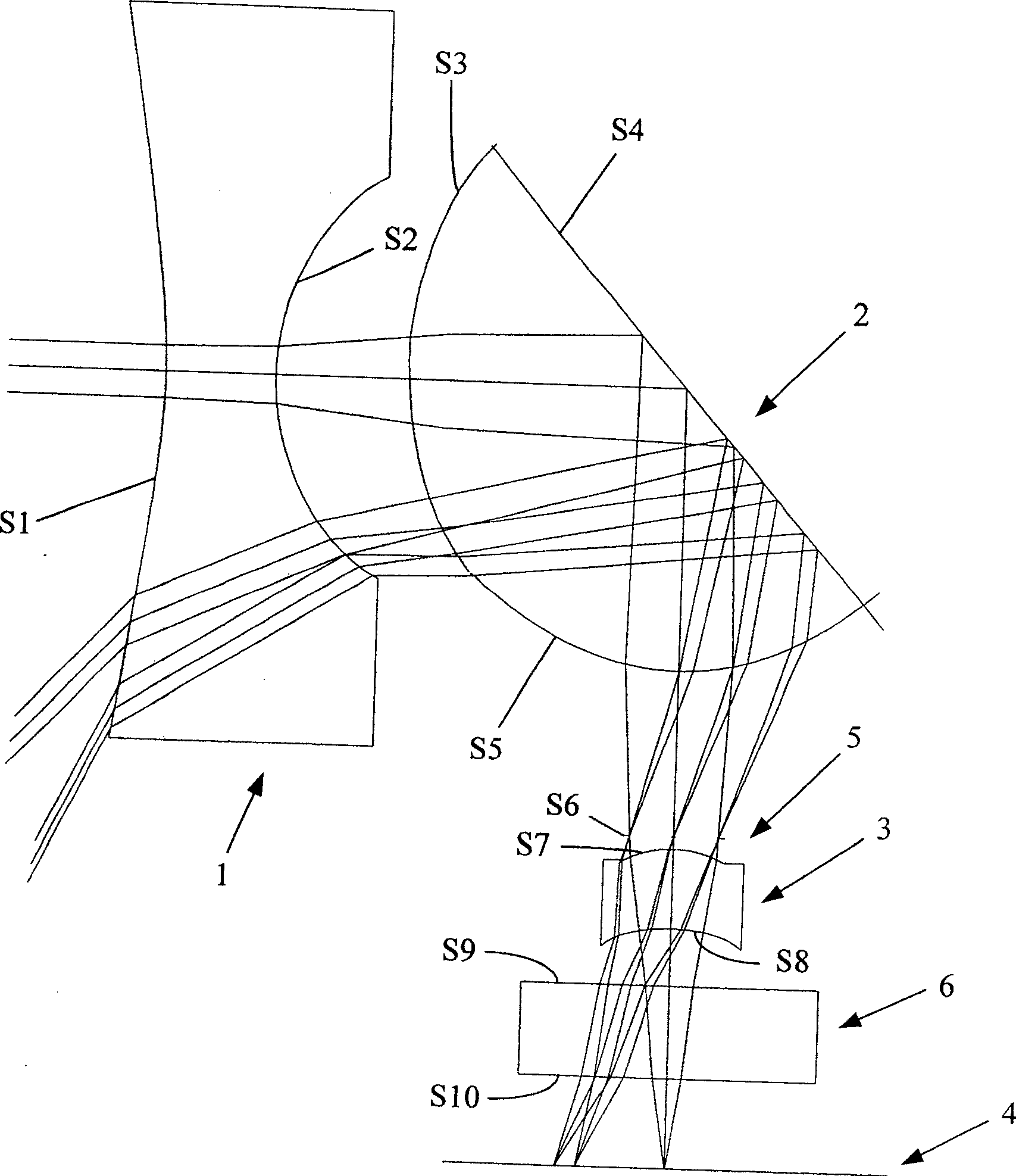

[0056] Such as Figure 7 As shown, the second embodiment of the miniature imaging lens of the present invention includes a first lens 12 of negative diopter, a free-form surface prism 22 of positive diopter, an aperture stop 52, a second lens 32 of positive diopter, and a glass plate 62 and an imaging surface 42. The first lens 12 is a biconcave lens. Both the incident surface S32 and the outgoing surface S52 of the free-form surface prism 22 are convex, and the reflecting surface S42 is a plane. The second lens 32 is a concave-convex lens. The specific values of each component are listed in the table below:

[0057]

Surface serial number Radius of curvature (mm)

(Radius of

Curvature) Distance / thickness(mm)

(Distance / Thickness) Refractive index

(Nd) Abbe number

(Vd) S0 ∞ S12 -6.0 1.05 1.5136 57.4 S22 2.04 1.80 S32 9.184 2.843 1.5136 57.4 S42 ∞ -3.0 1.5136 57.4 S52 2.216 -1.5 S6...

Embodiment 3

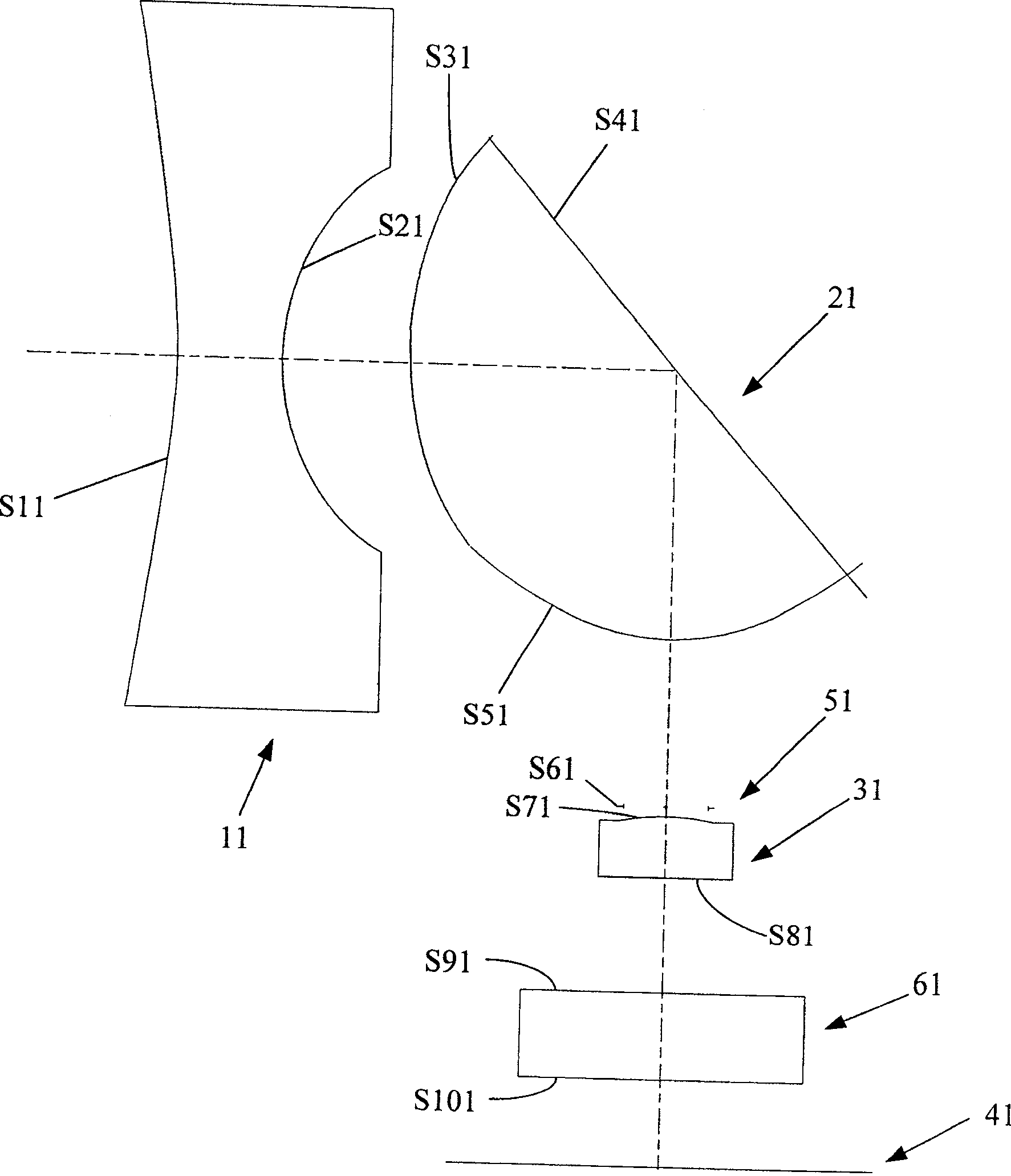

[0069] Such as Figure 12 As shown, the third embodiment of the miniature imaging lens of the present invention includes a first lens 13 of negative diopter, a free-form surface prism 23 of positive diopter, an aperture stop 53, a second lens 33 of positive diopter, and a glass plate 63 and an imaging surface 43. The first lens 13 is a biconcave lens. Both the incident surface S33 and the outgoing surface S53 of the free-form surface prism 23 are convex, and the reflecting surface S43 is a plane. The second lens 33 is a concave-convex lens. The specific values of each component are listed in the table below:

[0070] Surface serial number Radius of curvature (mm)

(Radius of Curvature) Distance / thickness(mm)

(Distance / Thickness) Refractive index

(Nd) Abbe number

(Vd) S0 ∞ S13 -4.40 1.1 1.5136 57.4 S23 1.90 1.70 S33 3.714 2.463 1.5136 57.4 S43 ∞ -2.643 1.5136 57.4 S53 2.698 -1.448 S63 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com