Dust aspirator motor

A vacuum cleaner and motor technology, which is applied in the installation of vacuum cleaners, suction filters, motor fan assemblies, etc., can solve the problems of complex mold making of the front bracket, affecting the working life of the vacuum cleaner, and worsening the performance of the vacuum cleaner, etc. Compact structure and the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with the best embodiment shown in the accompanying drawings, it will be further described in detail.

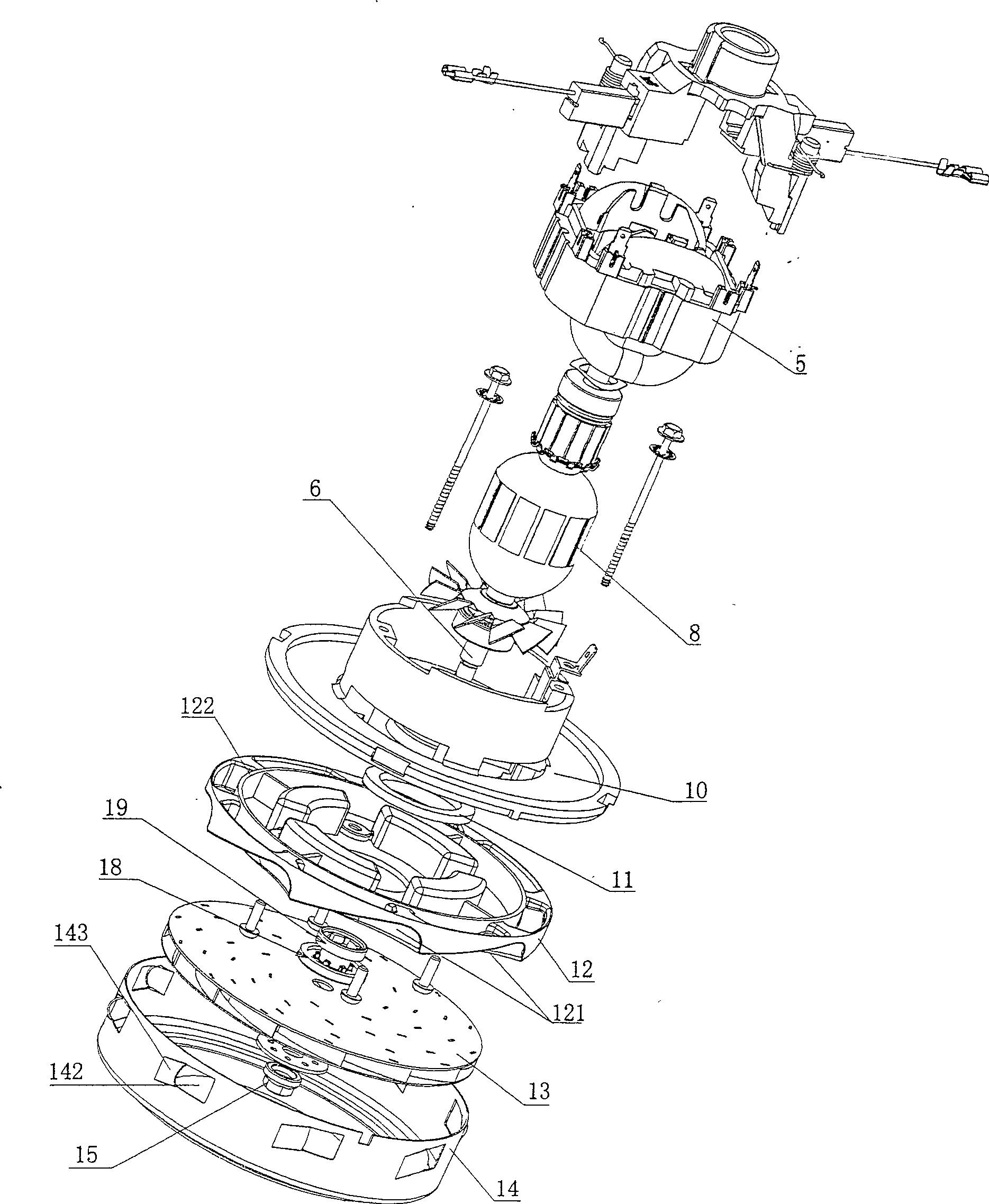

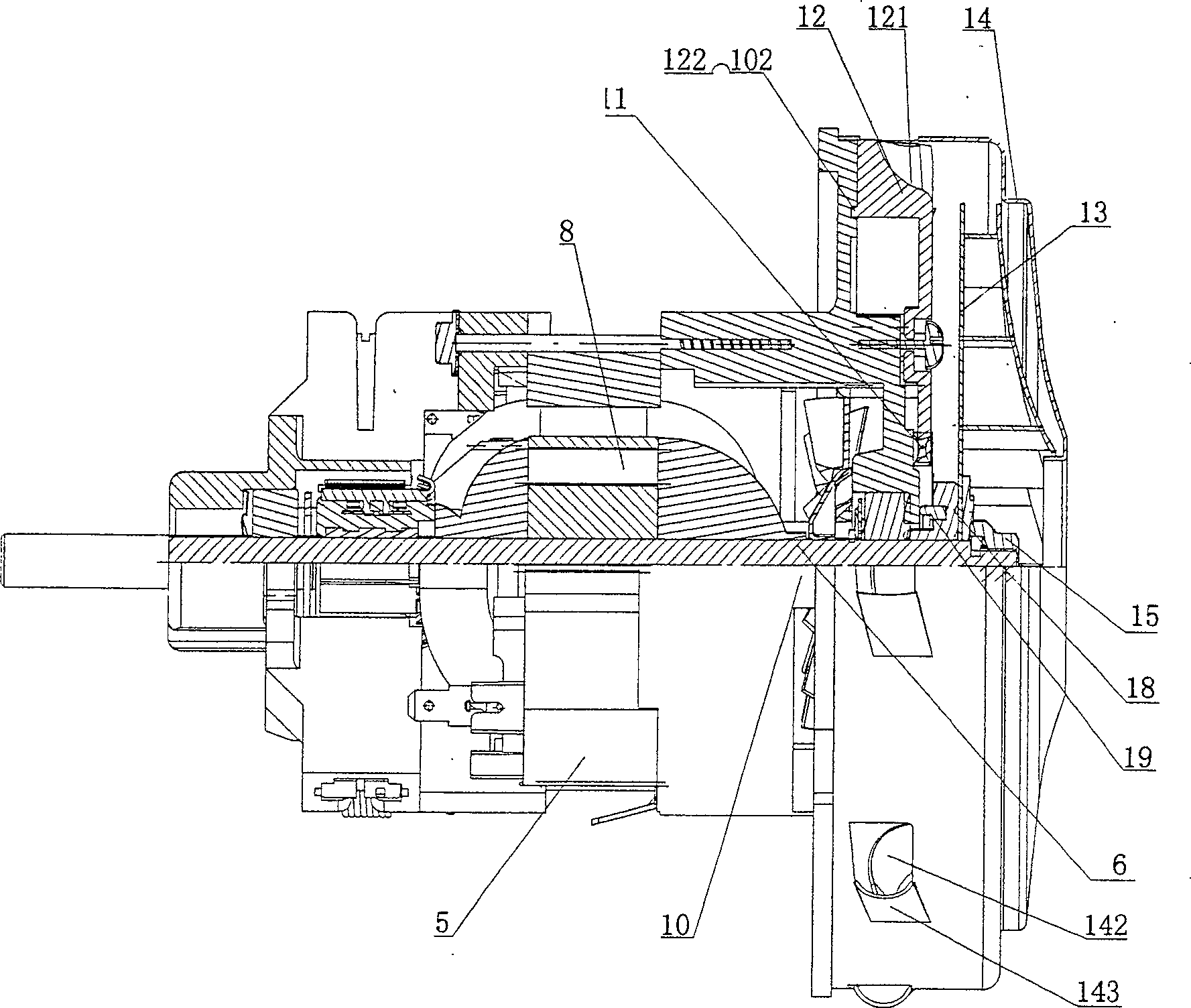

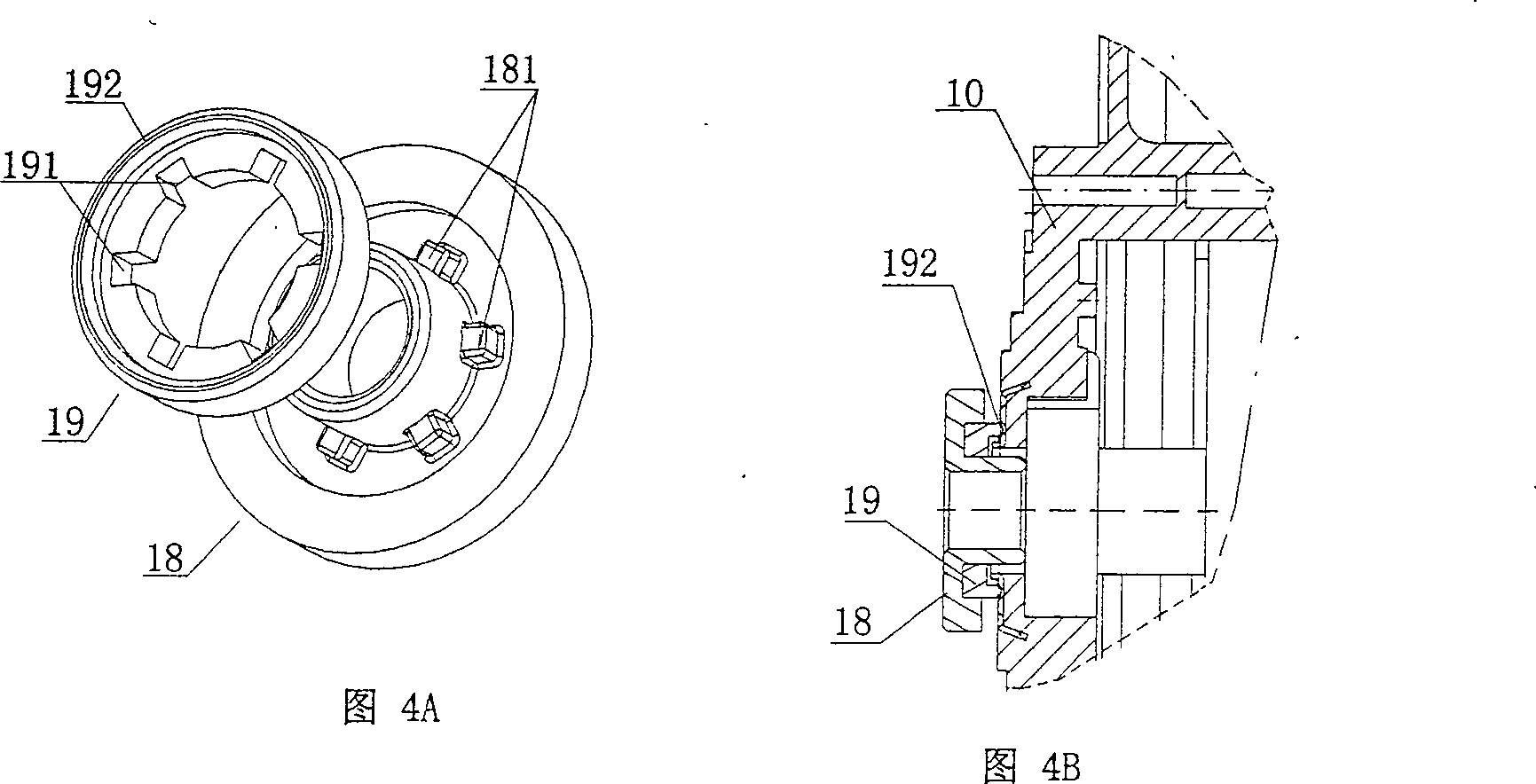

[0019] The vacuum cleaner motor device of the present invention, such as figure 1 and figure 2 As shown, it includes a motor assembly and a diffuser assembly; the motor assembly includes a stator 5, a rotor 8, an output shaft 6, and a front bracket 10; the diffuser assembly includes a wind deflector 12, a centrifugal wind wheel 13 and a windshield 14; The front end of the windshield 14 is an air inlet, and a plurality of air outlets 142 are arranged around; Centrifugal wind wheel 13; the output shaft 6 is provided with a shaft sleeve 18 at the place just protruding from the front bracket 10, so that the output shaft 6 is rotatably supported on the front bracket 10. Such as Figure 1 to Figure 3 As shown, the front bracket 10 is generally in the shape of a hollow cylinder, and most of its outer peripheral flange is an annular plane 101, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com