Disk device

A drive device and disc technology, applied in the direction of reducing the influence of temperature on the carrier, instruments, record carrier structural parts, etc., can solve problems such as errors, adverse effects of support movement, error readout, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

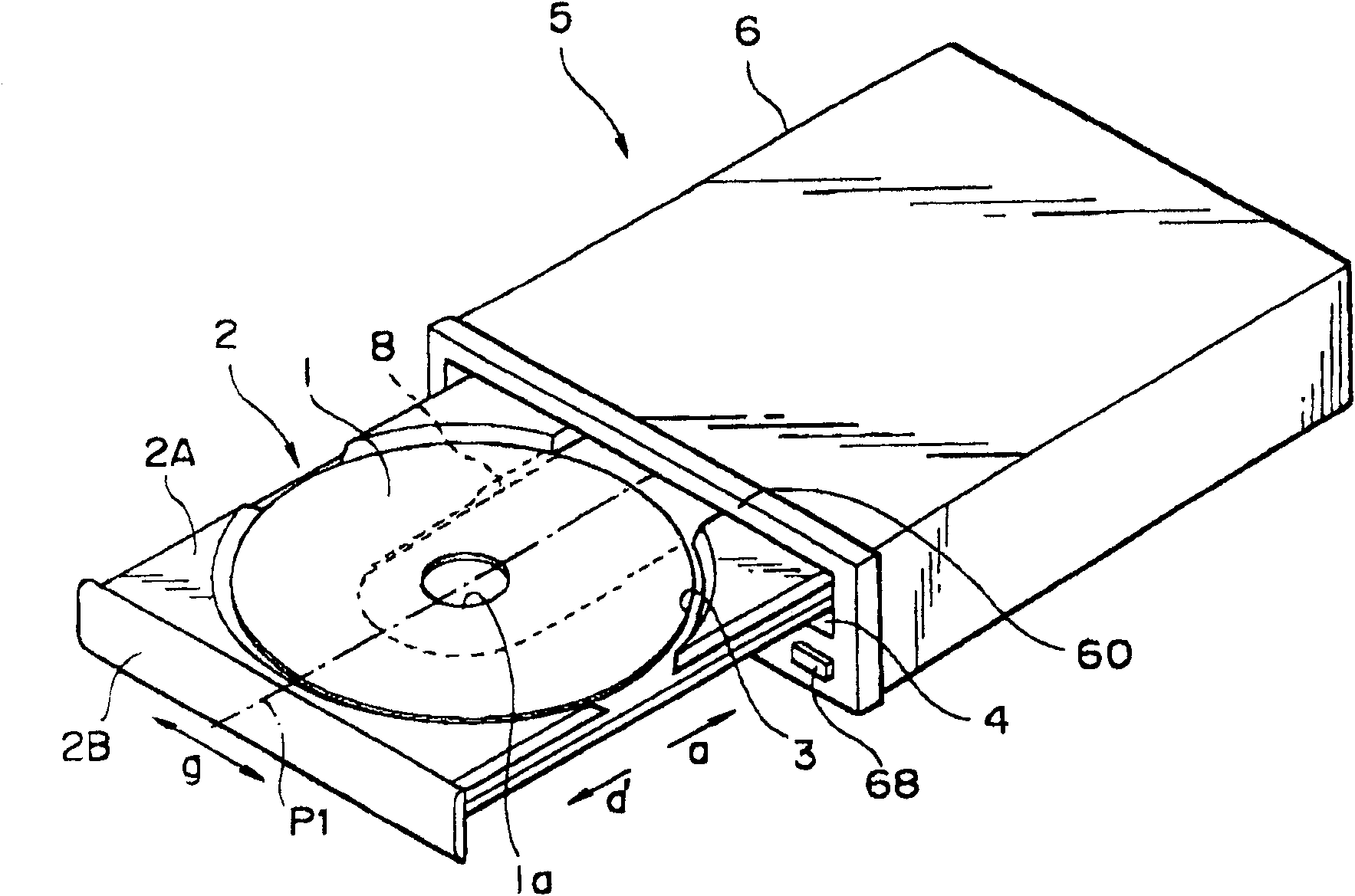

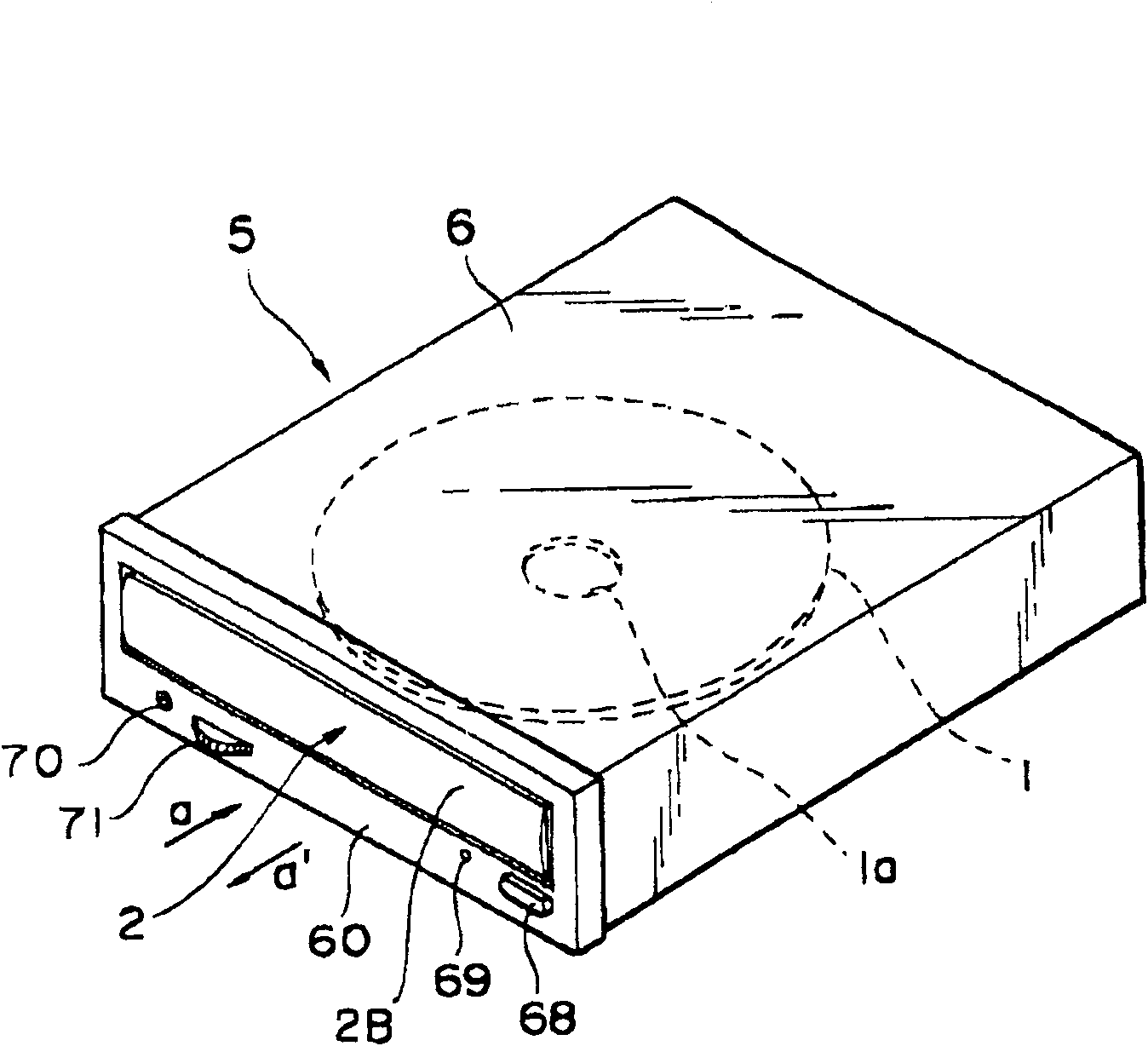

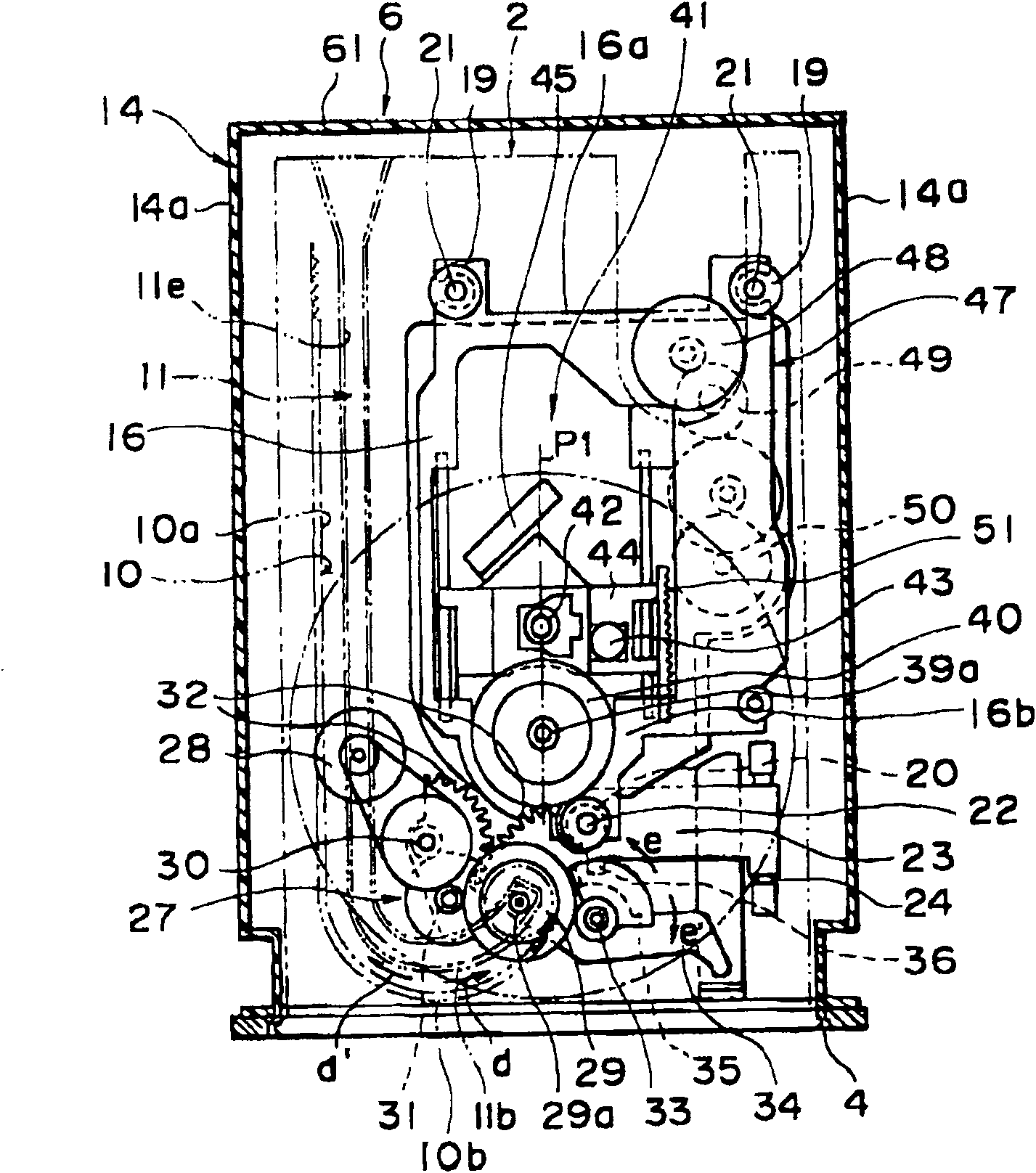

[0067] The following will refer to the attached Figures 15 to 17 An embodiment of an optical disk drive apparatus employing the present invention will be described. which with Figures 1 to 10 The same structural components in the above all use the same symbols and will not be described again.

[0068] The dustproof structure of the optical disc drive will be described below.

[0069] First combine the Figures 15 to 20 The dust-proof structure of an optical disk drive device 5 will be described.

[0070] Such as Figures 15 to 20 As shown, a plurality of elongated air inlets 74 are formed on the front panel 60 of the optical disc drive body 6 , and they are located on a horizontal (horizontal) line along the outside of the lower edge of the tray inlet and outlet 4 . A gap is provided between the lower cover 63 of the disk drive body 6 and the printed circuit boards 64 , 65 to serve as an air intake passage 75 . The front end of the air intake passage 75 (on the side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com