The automatic coordination device of the partial assembly line and the main assembly line of the loader cab

A cab and assembly line technology, which is applied in the field of automatic coordination devices for loader cab part assembly line and main assembly line, can solve the problems of potential safety hazards, high labor intensity, and low work efficiency, so as to improve transfer efficiency and reduce labor intensity , Improve the effect of process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

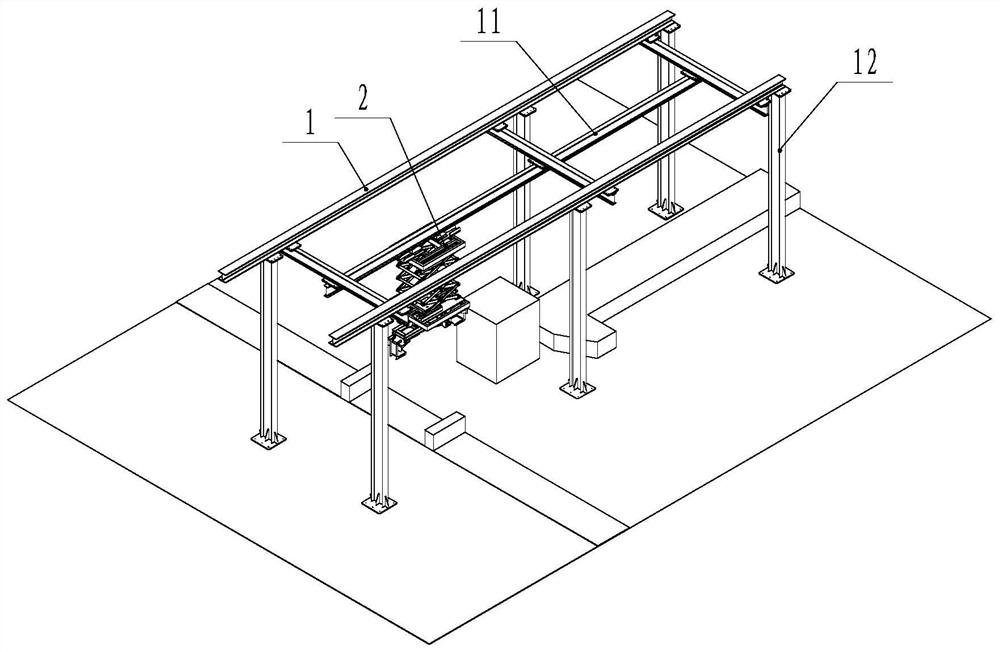

[0027] like figure 1 As shown, the automatic coordination device for loading the cab part of the loader cab and the main assembly line includes a frame 1, a column 12 is arranged under the frame 1, a track 11 is installed on the frame 1, and a working tool that can move left and right is arranged on the track 11. device 2;

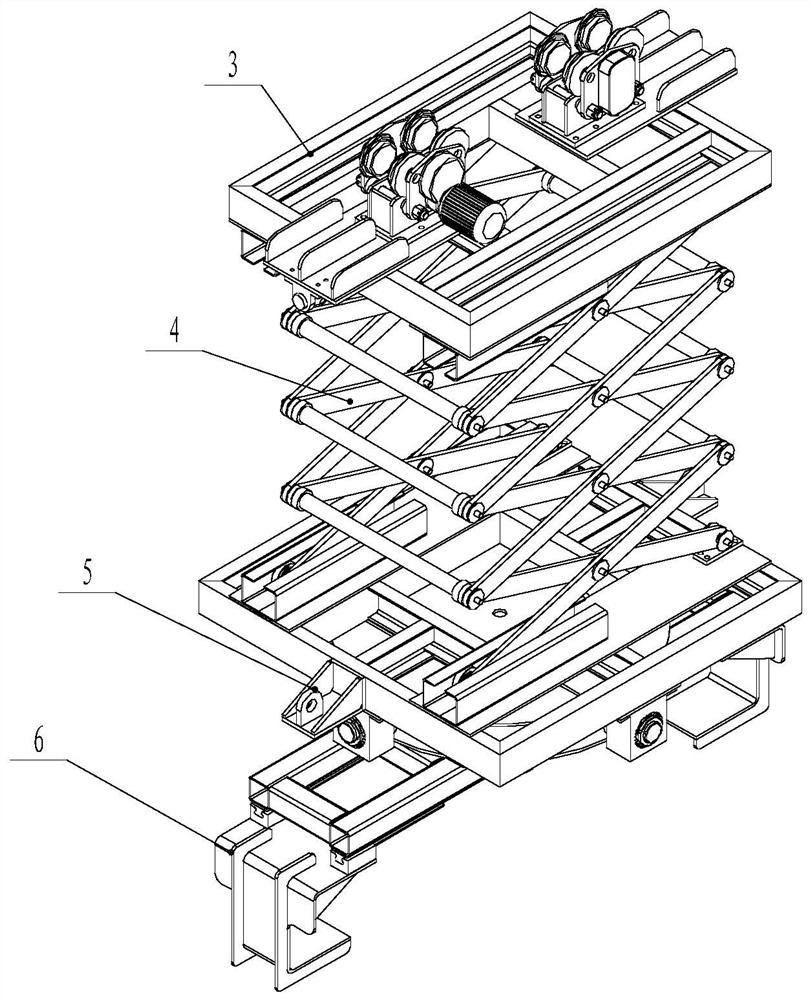

[0028] like figure 2 As shown, the working device 2 includes a traveling mechanism 3, which cooperates with the track 11. A hinged mechanism 4 that can be stretched up and down is provided below the traveling mechanism 3. A rotatable turning mechanism 5 is provided at the bottom of the hinged mechanism 4. The turning mechanism Below the 5 is provided with a fine-tuning jaw mechanism 6 that can move back and forth and clamp left and right.

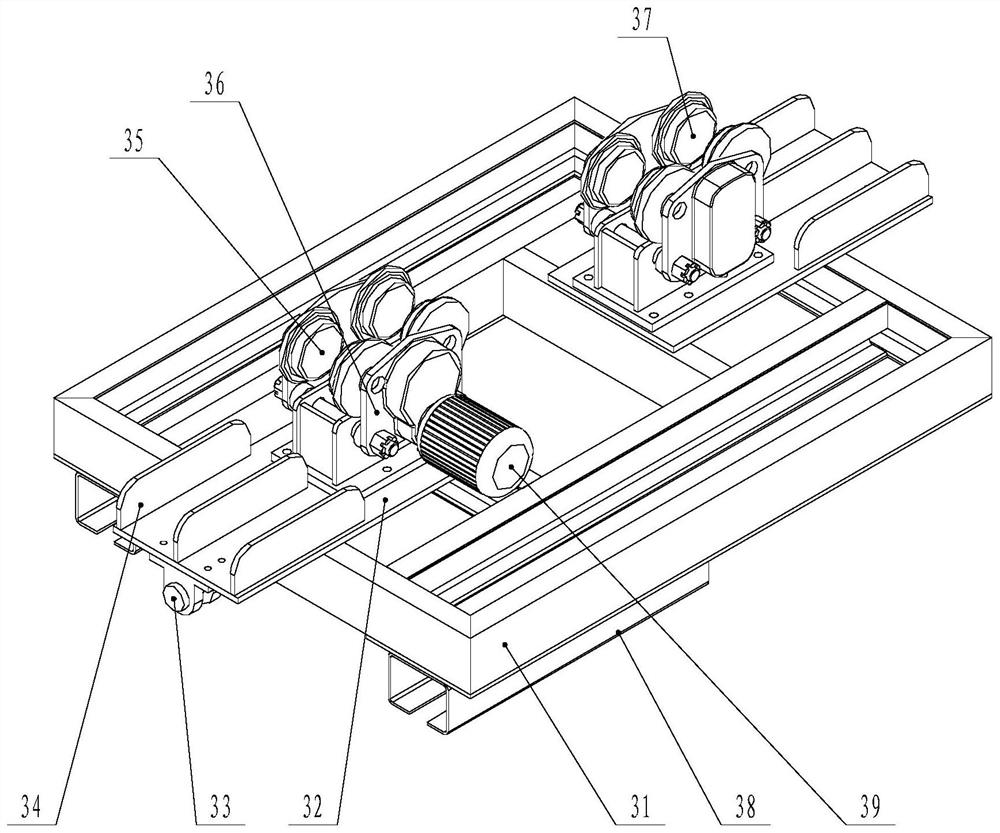

[0029] like image 3 As shown, the traveling mechanism 3 includes a trolley support 31, the bottom of the tro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com