Drum type washing machine

A drum-type washing machine and drum technology, which is applied to other washing machines, washing machines with containers, washing devices, etc., can solve the problems of difficulty in flowing out the thread, increasing the amount of residual thread in the laundry, and inability to remove the thread-capturing filter for cleaning, etc. To achieve the effect of easy cleaning and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 of the present invention will be described with reference to the drawings.

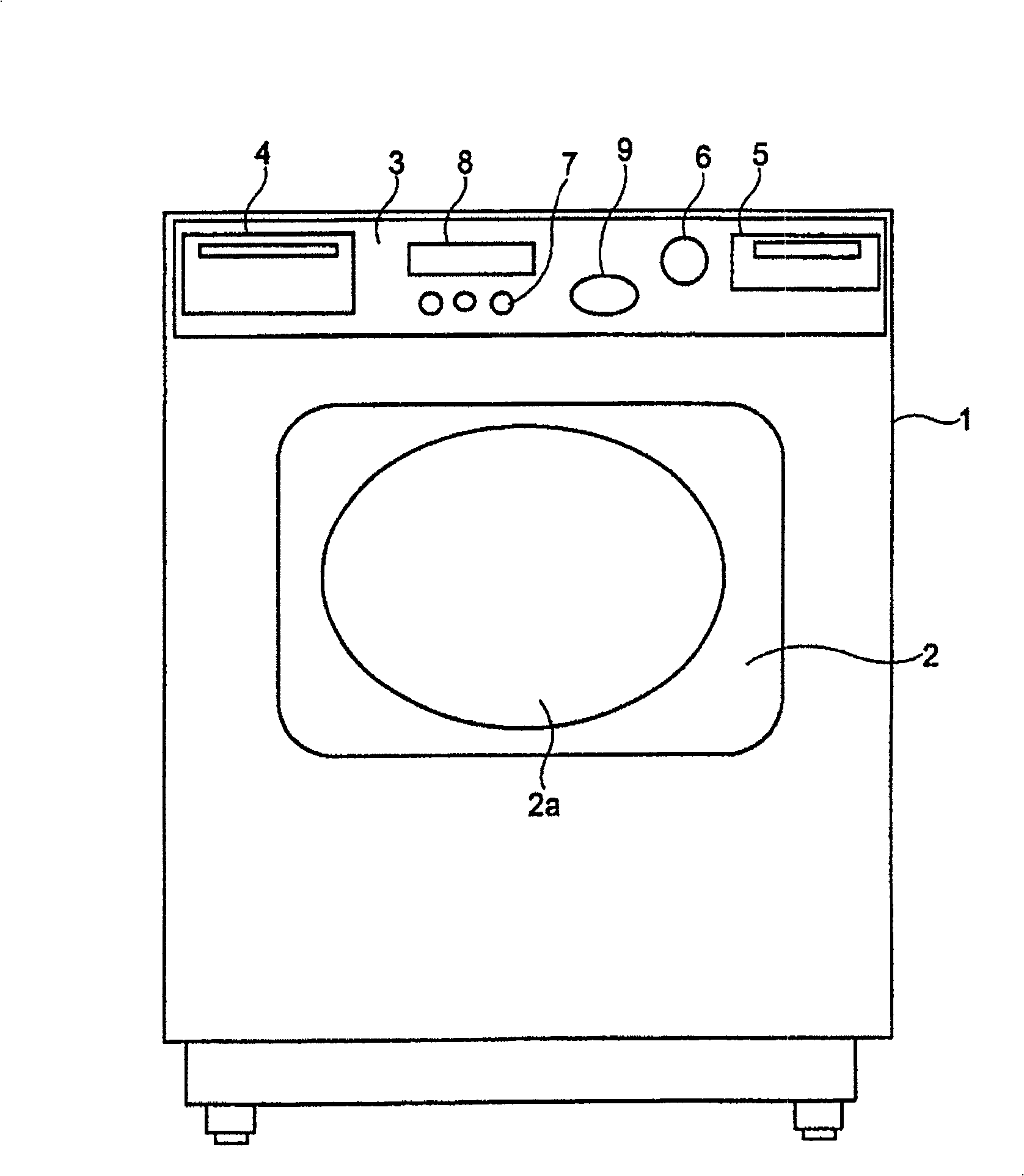

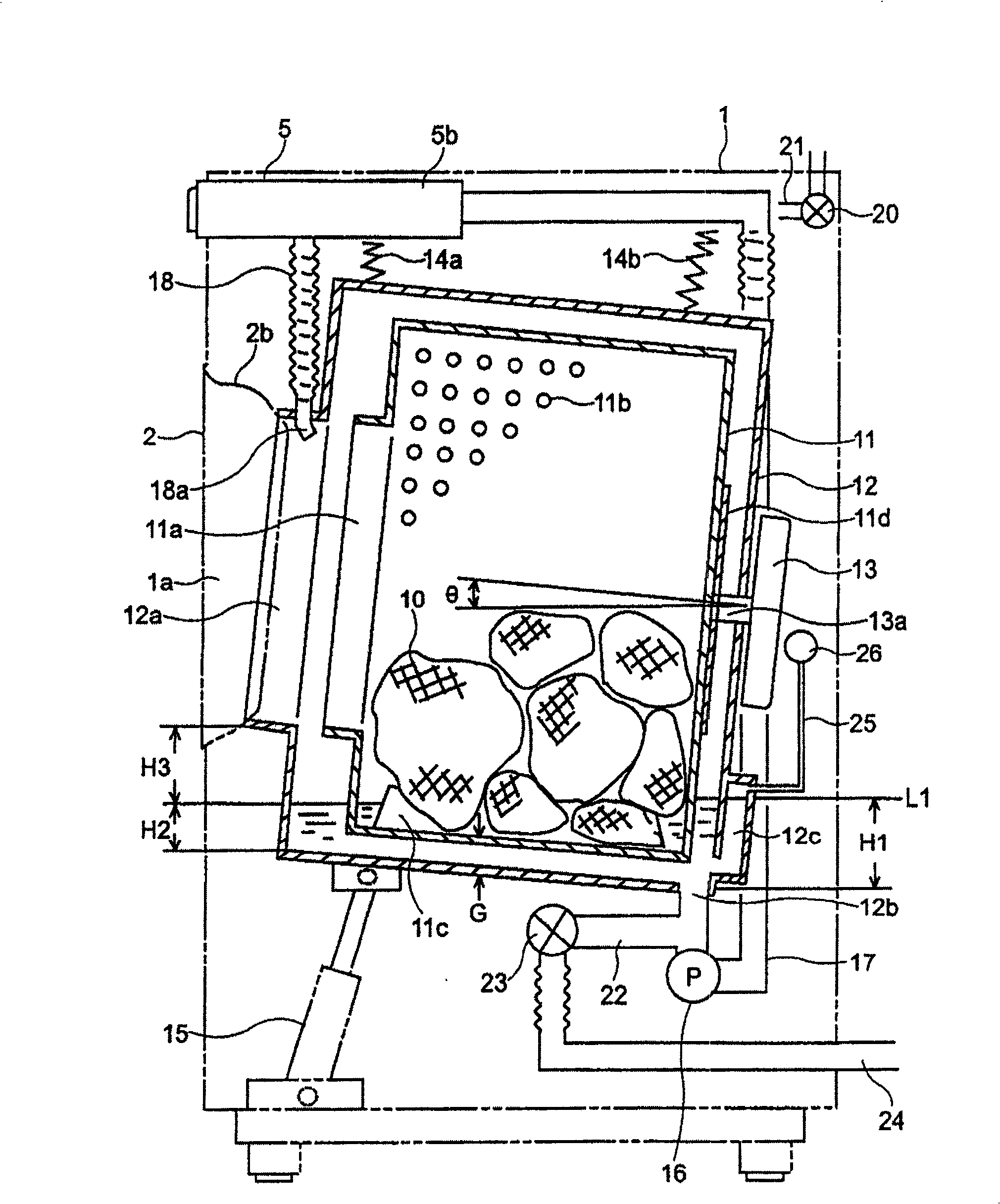

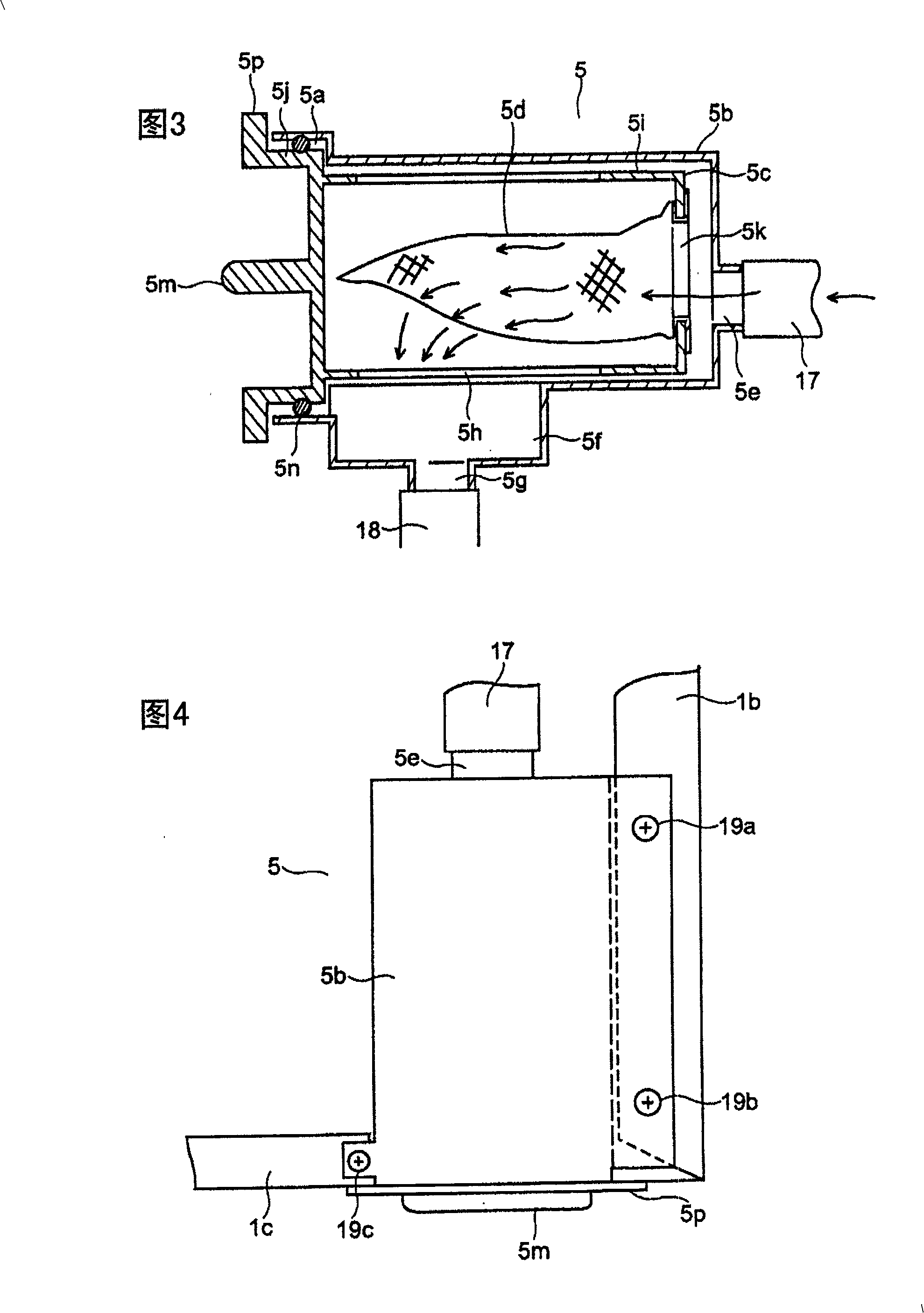

[0026] figure 1 It is the front view of the front-loading-type washing machine of Example 1, figure 2 is a longitudinal sectional side view of its internal mechanism, image 3 is a longitudinal sectional side view of the thread catcher mechanism, Figure 4 It is a plan view showing the installation structure of the lint trap mechanism to the outer frame, with the top plate removed, Figure 5 It is an exploded perspective view showing the attachment structure of the thread capture mechanism to the outer frame.

[0027] The outer frame 1 of the drum-type washing machine of Embodiment 1 is in the shape of a box, and the clothing loading and unloading window 1a formed at a position slightly higher than the center of the front central part can be covered by the clothing loading and unloading cover 2 with a transparent window 2a. It is constructed so that it can be opened and closed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com