Plane luminous display with high-colority contrast structure and its making process

A light-emitting display, chromaticity contrast technology, applied in the manufacture of discharge tubes/lamps, image/graphic display tubes, cold cathode manufacturing, etc., can solve the problems of increasing the black level of the display, weakening the high brightness of the displayed image, etc. Inexpensive, reduced production costs, high-quality display image effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below with reference to the accompanying drawings and embodiments, but the present invention is not limited to these embodiments.

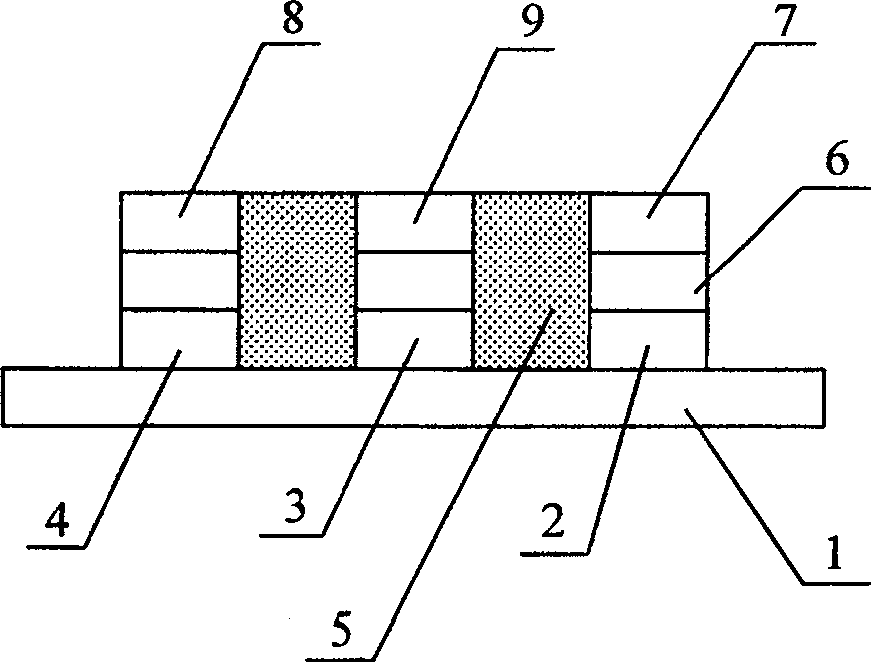

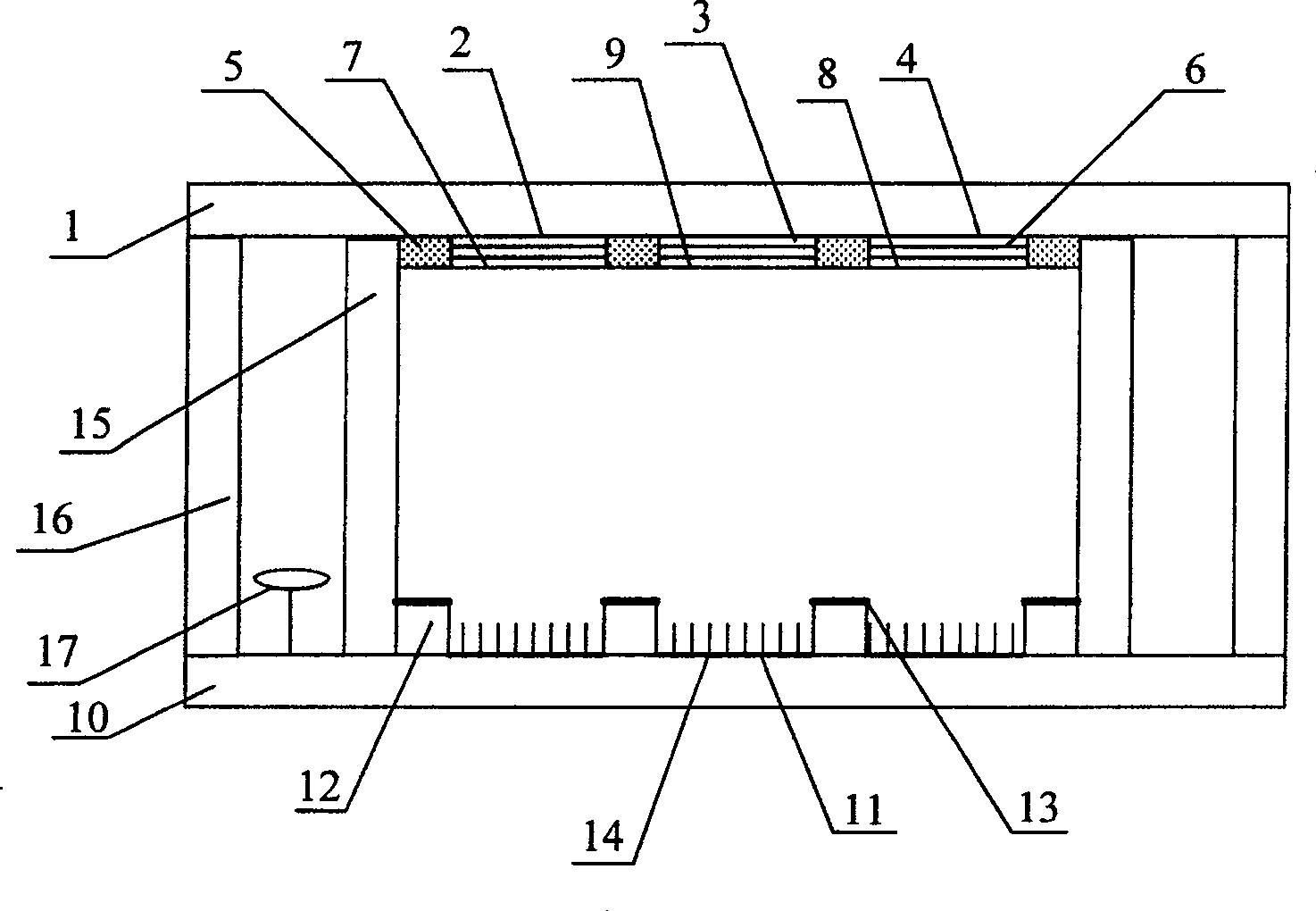

[0036] The present invention includes a sealed vacuum chamber composed of an anode substrate glass [1], a cathode substrate glass [10] and a surrounding glass frame [16], and the cathode substrate glass [10] is provided with cathode conductive strips [11] and A printed carbon nanotube cathode [14], a control grid for controlling electron emission [13], a prepared phosphor layer on the anode substrate glass [1], a support wall structure [15] and its accessory getter [1] 16] Element, characterized in that a high chromaticity contrast structure is mounted on the anode panel.

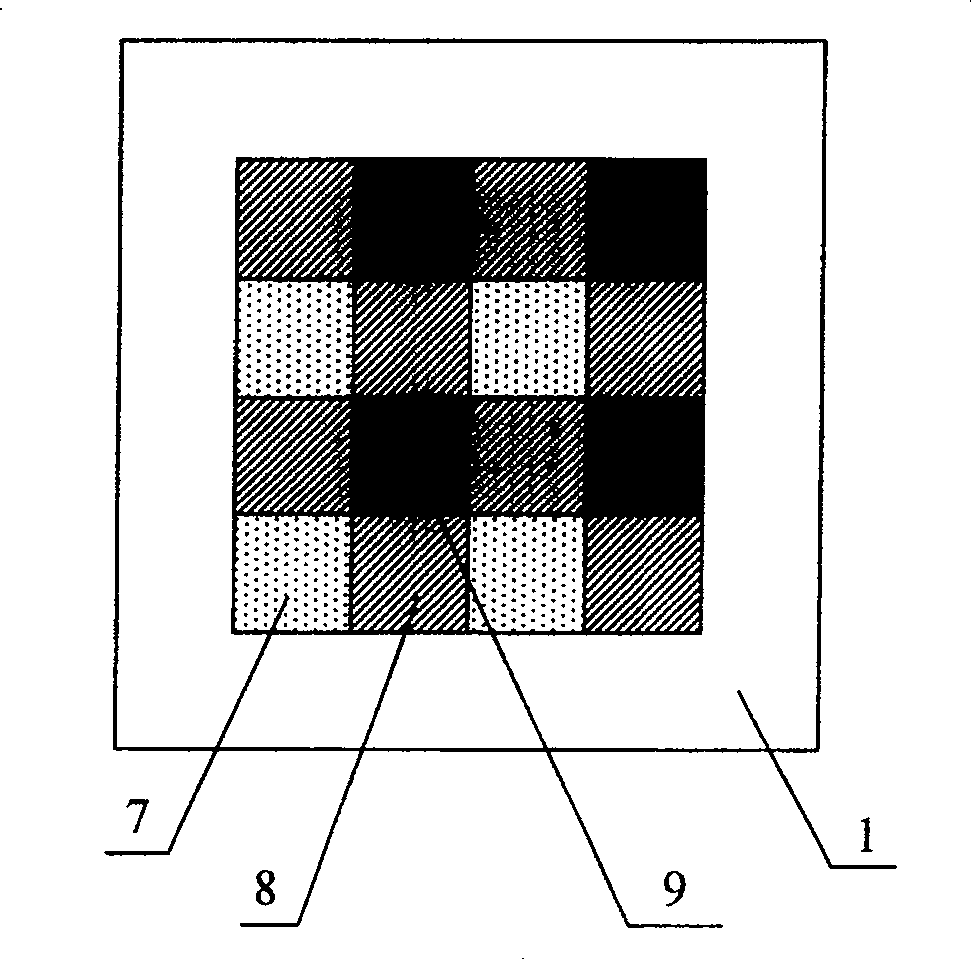

[0037] The high chromaticity contrast structure includes an anode substrate [1], a red filter layer [2], a blue filter layer [3] and a green filter layer [4] disposed on the anode substrate [1] , the anode insulating layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com