Track for a railborne vehicle, comprising a long-stator linear drive comprising at least one long stator, and a kit and a stator packet for the production thereof

A technology for rail vehicles and stator cores, applied in electric components, tracks, propulsion systems, etc., can solve problems such as high manufacturing and installation costs, achieve low power loss, improve energy balance, and reduce width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

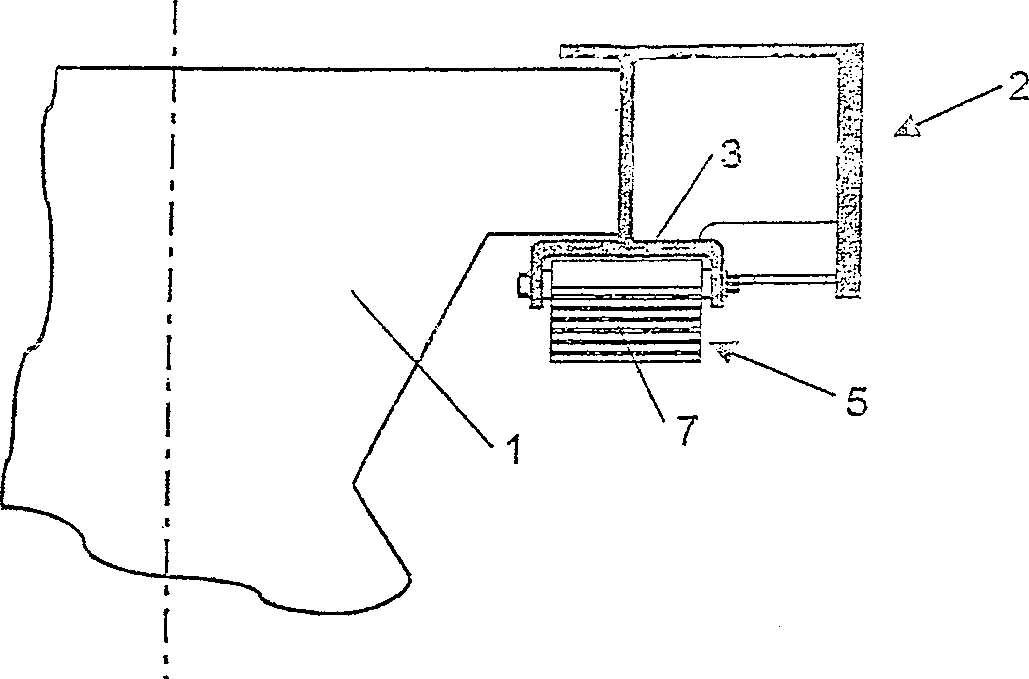

[0047] figure 1 Shown is a section through a cross-section of a support beam 1, on one side of which a functional part 2 is arranged. The functional part 2 has a U-shaped stator load-bearing component 3 on which a stator core 5 is arranged. In order to suppress eddy currents, the stator core 5 can consist of mutually insulated stator laminations.

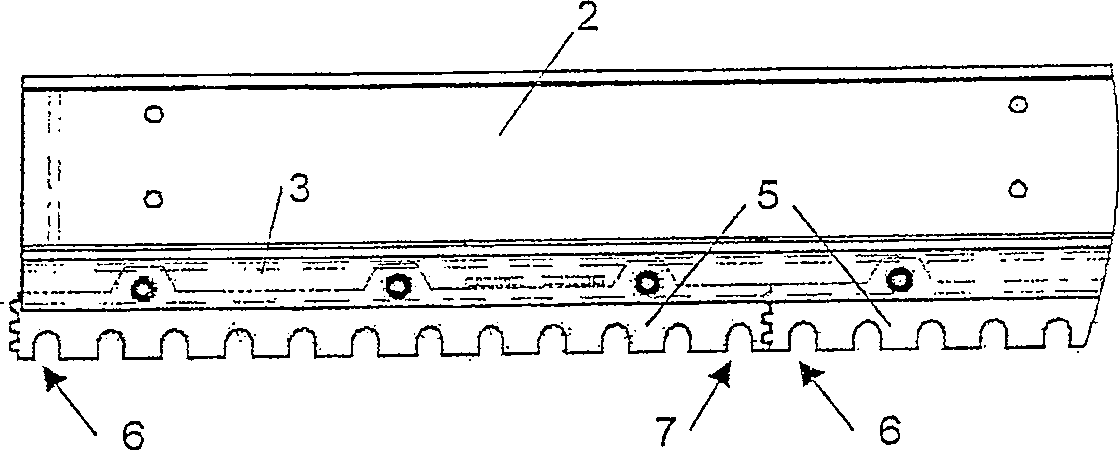

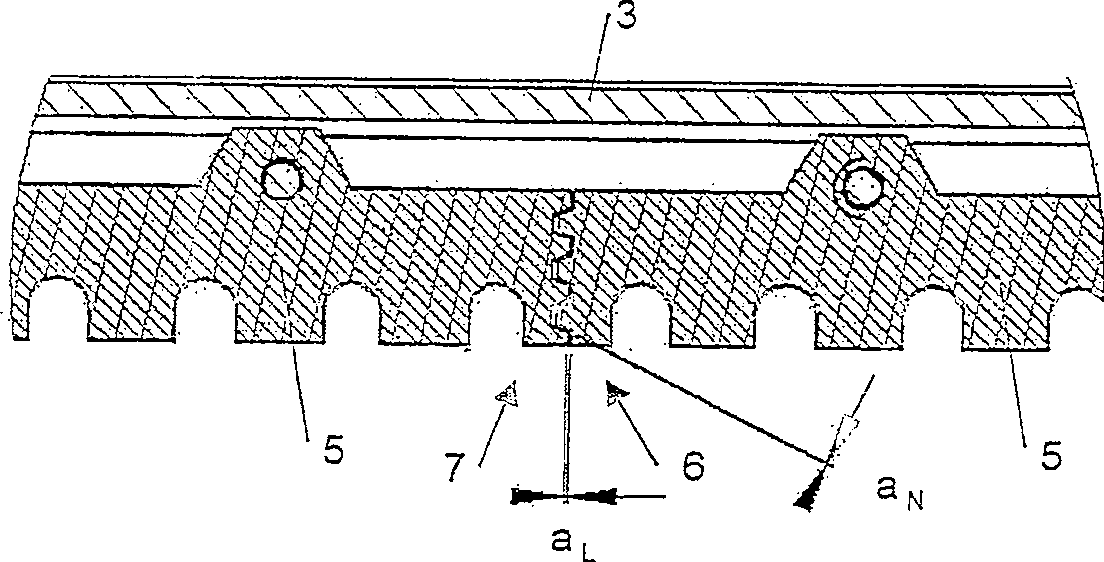

[0048] figure 2 Shown is part of a longitudinal section through the track. Arranged on the functional part 2 is a stator load-bearing component 3 , to which a stator core 5 is fastened with three screws each. The butt ends 6, 7 of the stator core 5 shown in the figure have recesses and protrusions, thus forming a vertically acting sawtooth shape. If, for example, the right and middle screws of the left stator core 5 are loosened, the stator core can still be held in its position by means of the saw-tooth shape and the U-profile of the stator load-bearing part. Loose bolts can be caused, for example, by vibrations, corrosion da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com