Adsorptive rotary reversing device for producing disposable toilet paper

A technology of rotating reversal and toilet paper, applied in packaging, transportation and packaging, paper/cardboard containers, etc., can solve problems such as affecting production efficiency and economic efficiency, high product rejection rate, and inability to maintain a constant angle. , stable adsorption, easy adjustment and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

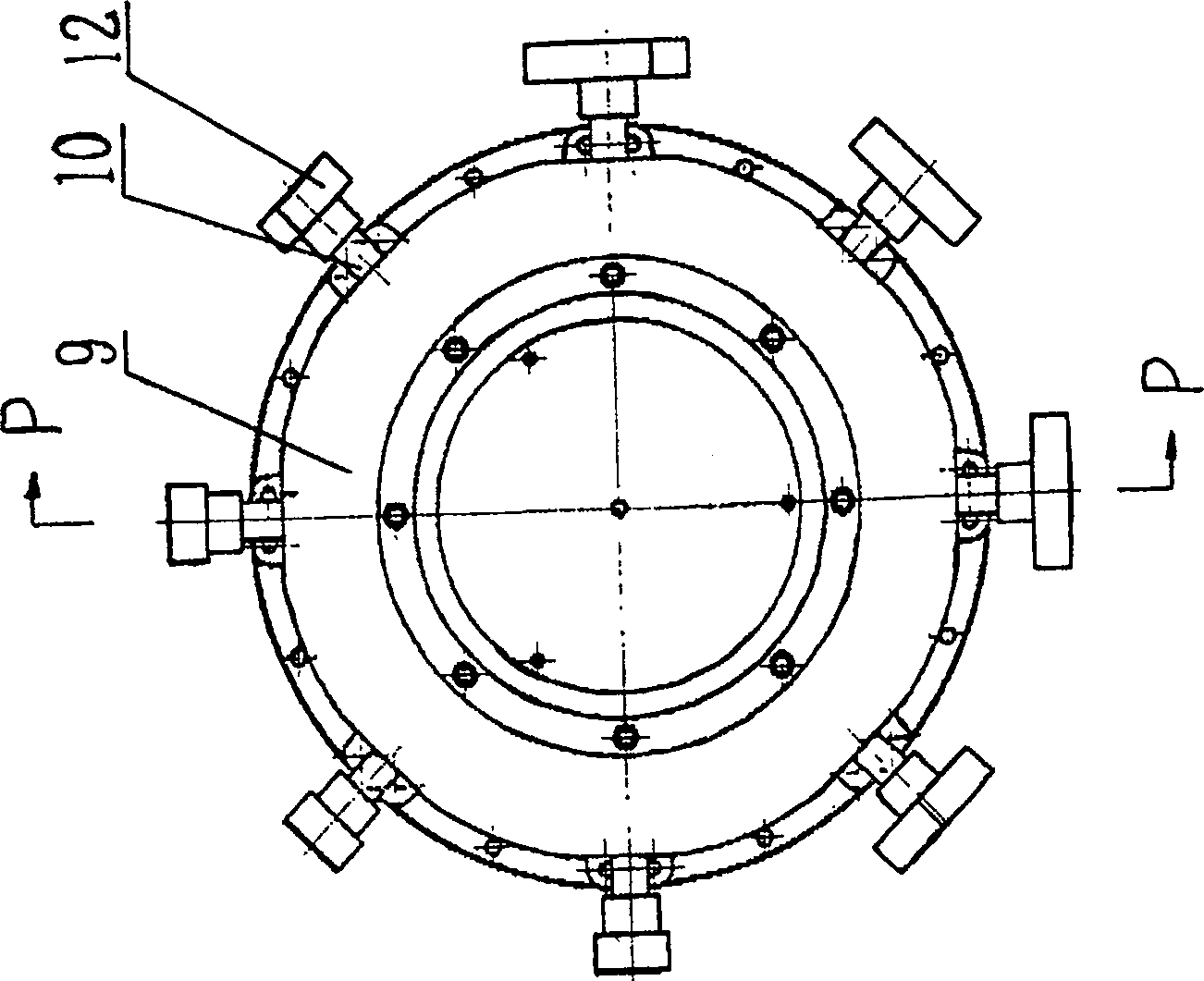

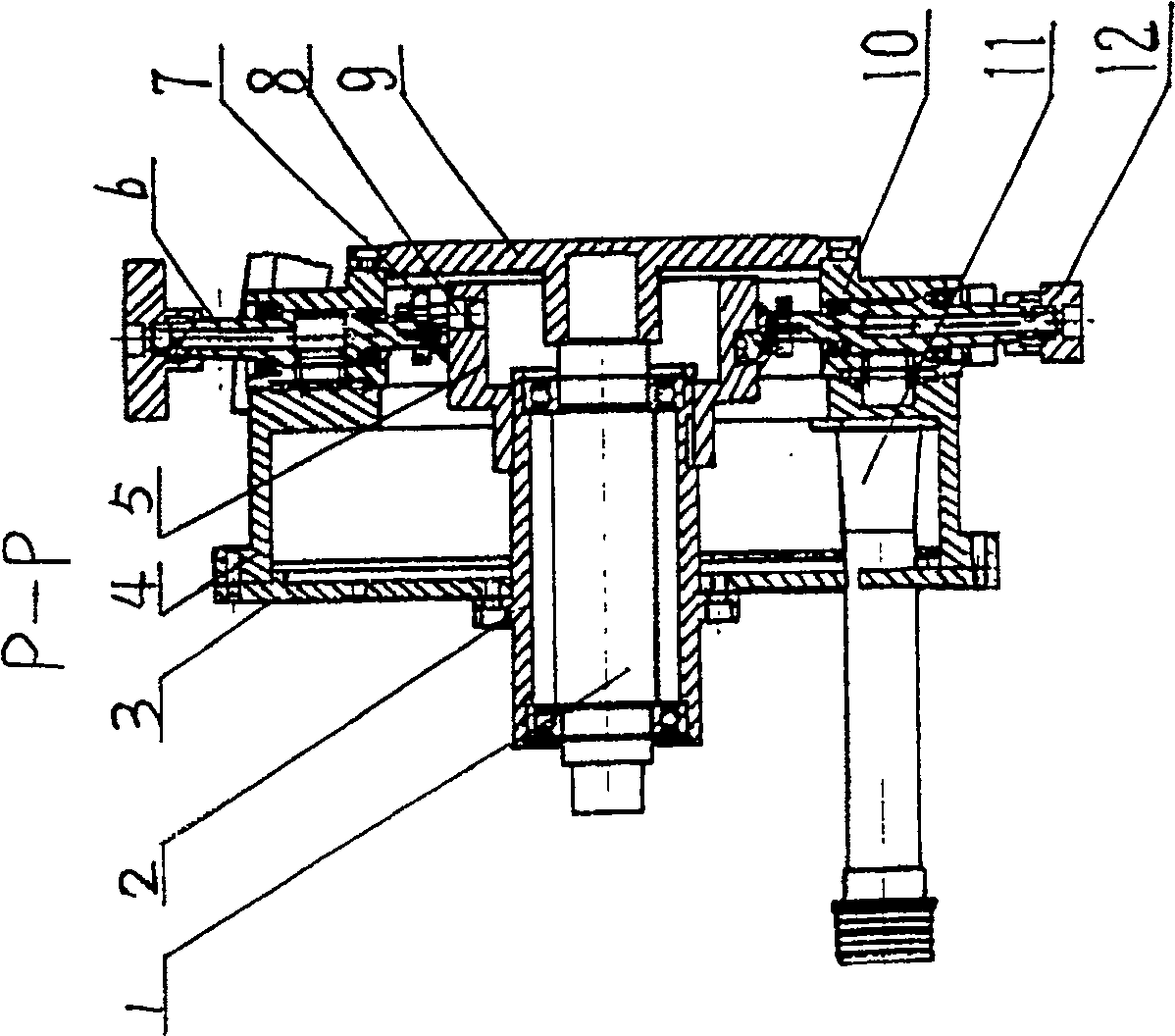

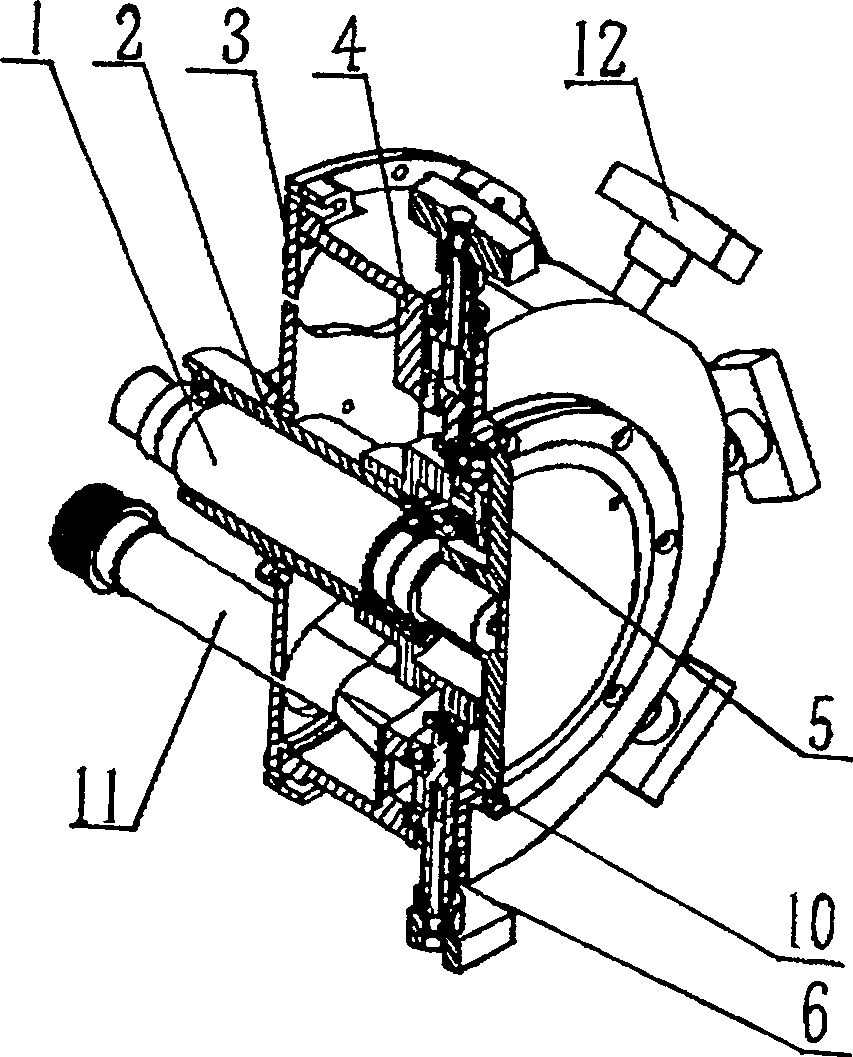

[0021] The adsorption rotary reversing device for the production of disposable sanitary paper products includes an air suction ring 4, and the axial end of one side of the air suction ring 4 is fixedly connected with the positioning plate 3, and the positioning plate 3 has a through hole, and the main bearing seat 2 is fixed on the positioning plate. On the disk 3, the axial end on the other side of the suction ring 4 is a rotating disk 10, the main shaft 1 is connected to the rotating disk cover 9 through the main bearing seat 2, the rotating disk cover 9 is connected to the rotating disk 10, and the rotating disk 10 is evenly distributed in the radial direction With more than four shaft holes, the hollow shaft 6 at the lower part of the suction cup 12 is set in the shaft hole of the rotating disk 10, and an air suction channel and a transmission mechanism are arranged between the main shaft 1 and more than four hollow shafts 6,

[0022] Described transmission mechanism is cam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com