Forming machine for straw in biomass

A biomass straw and molding machine technology, applied in ceramic molding machines, presses, manufacturing tools, etc., can solve the problems of high energy consumption and large investment, save money, simplify the process, and reduce the cost of equipment and supporting facilities. effect of input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

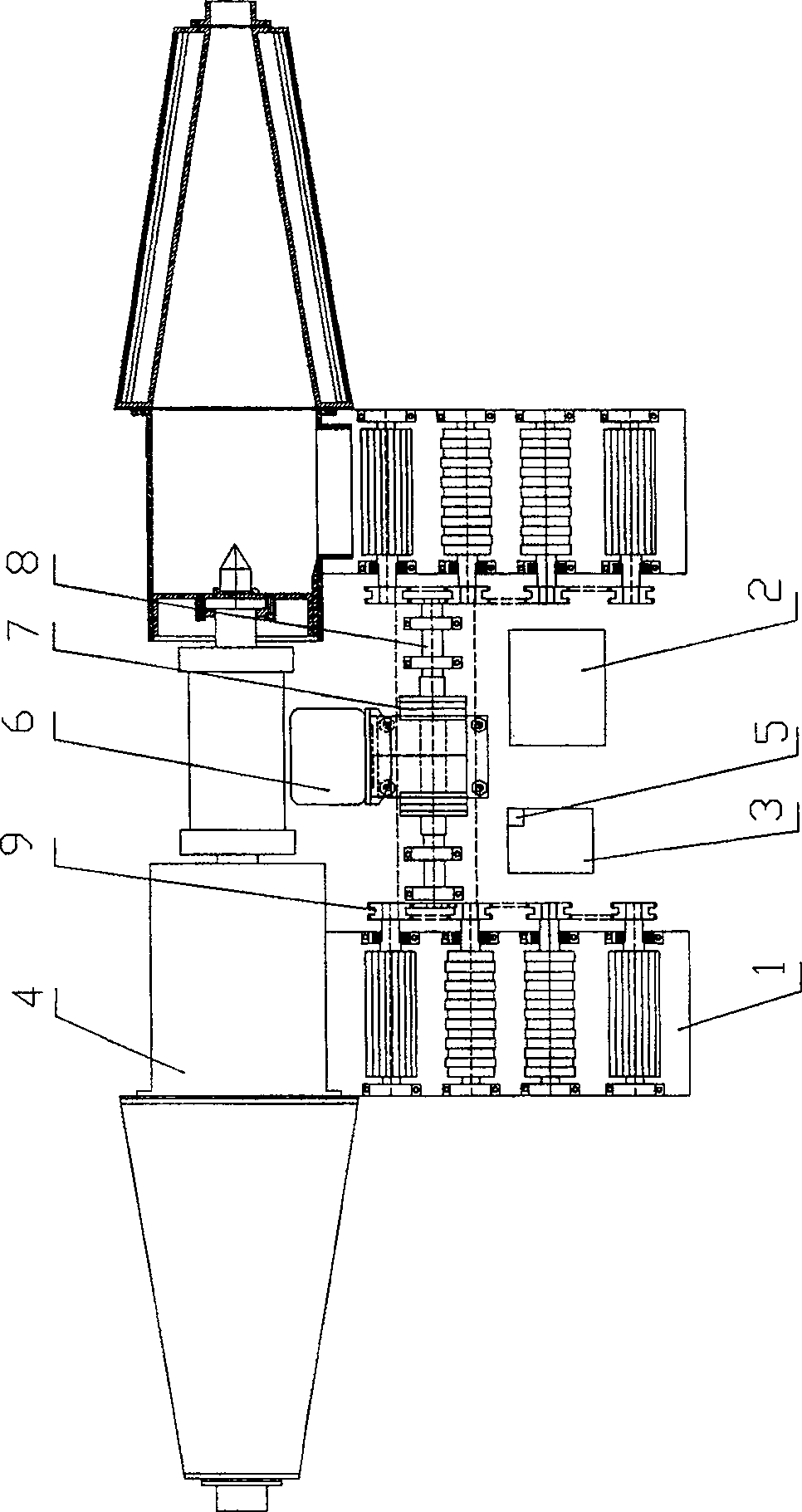

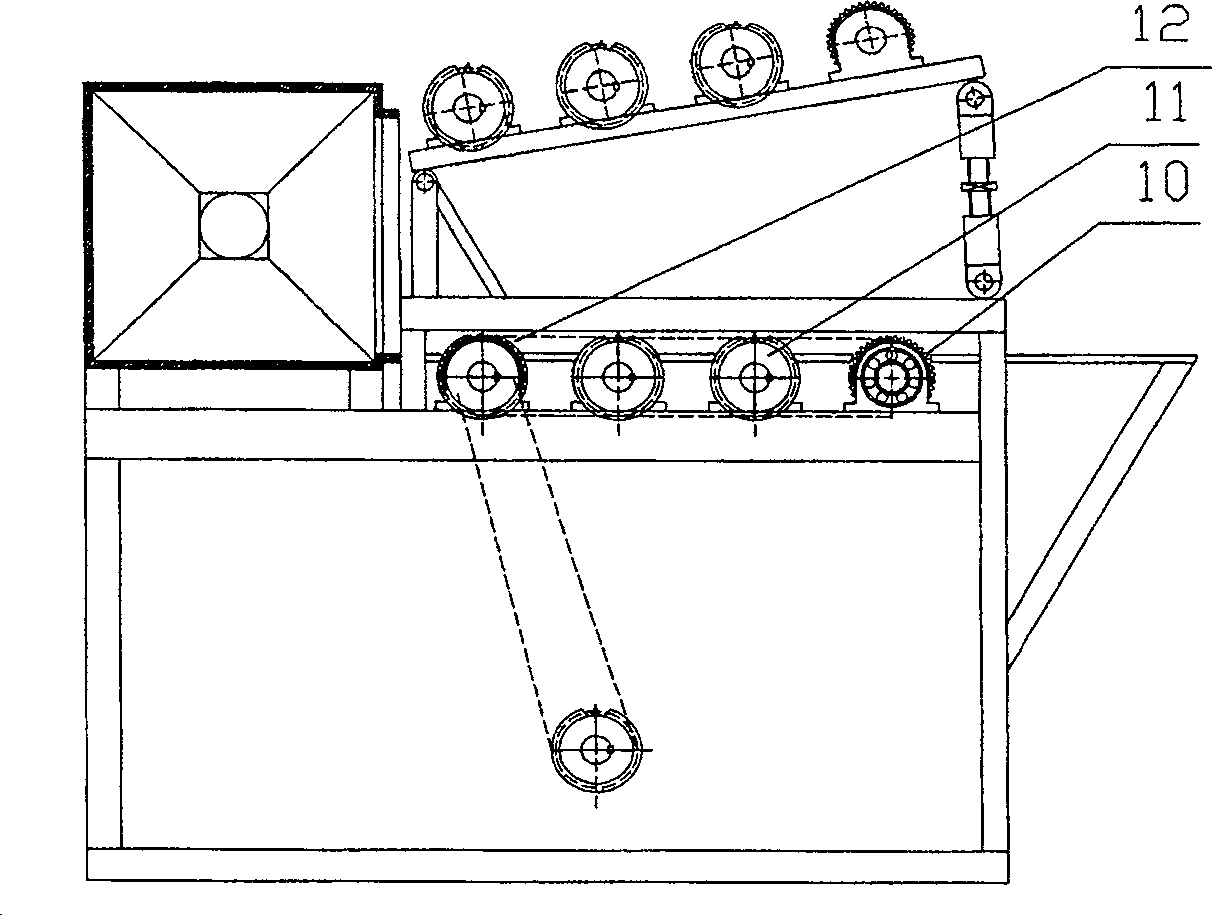

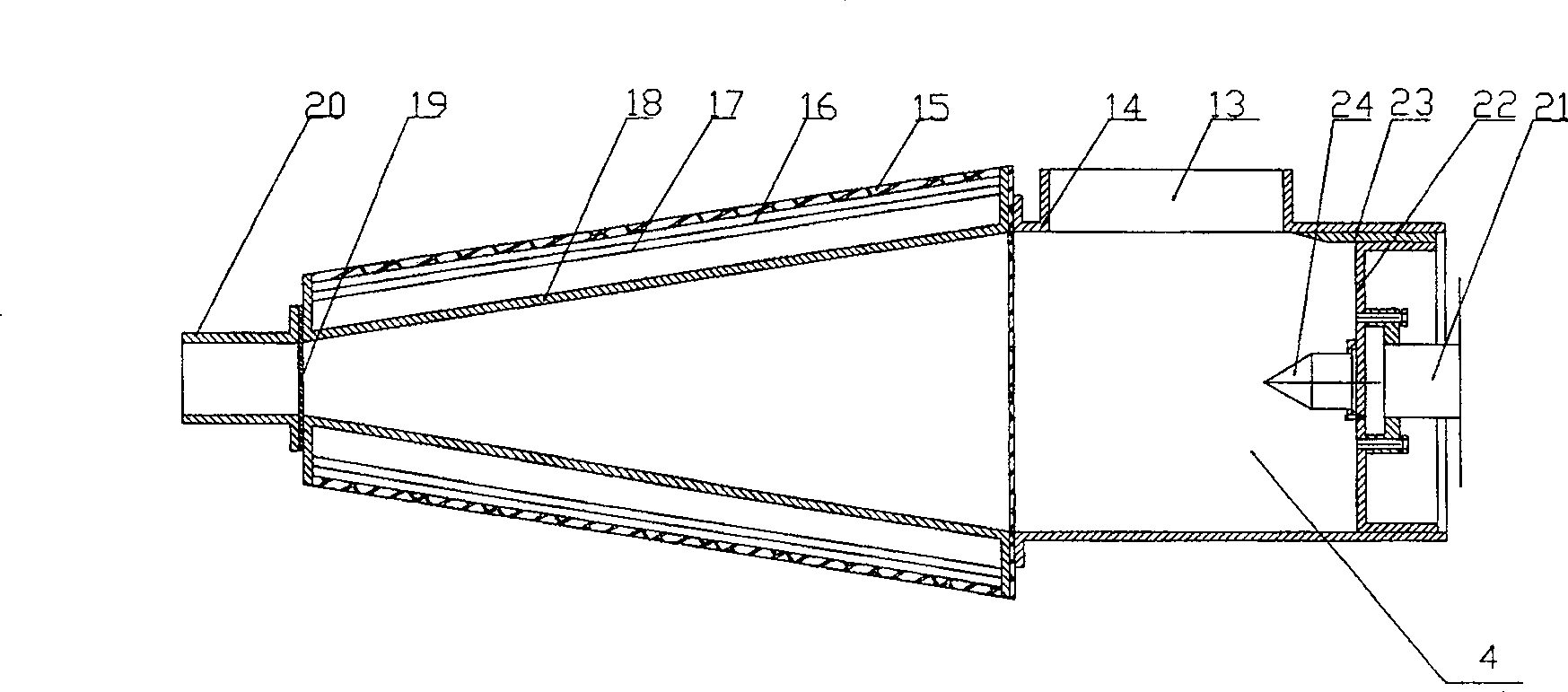

[0022] refer to figure 1 and figure 2 , the main components of a biomass straw molding machine are installed on the base frame, which is a frame structure made of steel in two parts, and the left side is a 1-shaped frame structure base frame (abbreviated as 1-shaped base frame ), the right side is an I-shaped frame structure base frame (abbreviated as I-shaped base frame). The middle position of the base frame is first fixed with double outlet oil cylinders, and the ends of the two piston rods 21 of the double outlet oil cylinders are respectively installed with a cutting knife 23 and an extrusion head 22 with a density adjustment head 24; The forming devices 4 with fixed far-infrared heaters are respectively installed at both ends, the shaping cylinders 20 of the two forming devices 4 face outward, and the central axes of the two forming devices 4 and the central axes of the two piston rods 21 of the double outlet cylinders are collinear , two extrusion heads 22 with cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com