Titanium material personalized skull-jaw facial bone renovation unit and preparation method thereof

A craniofacial and bone repair technology, applied in prosthesis, medical science, image data processing, etc., can solve the problems that the strength of titanium mesh cannot meet the requirements, structural defects are difficult to repair, and achieve excellent mechanical properties and ensure mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below with reference to the accompanying drawings.

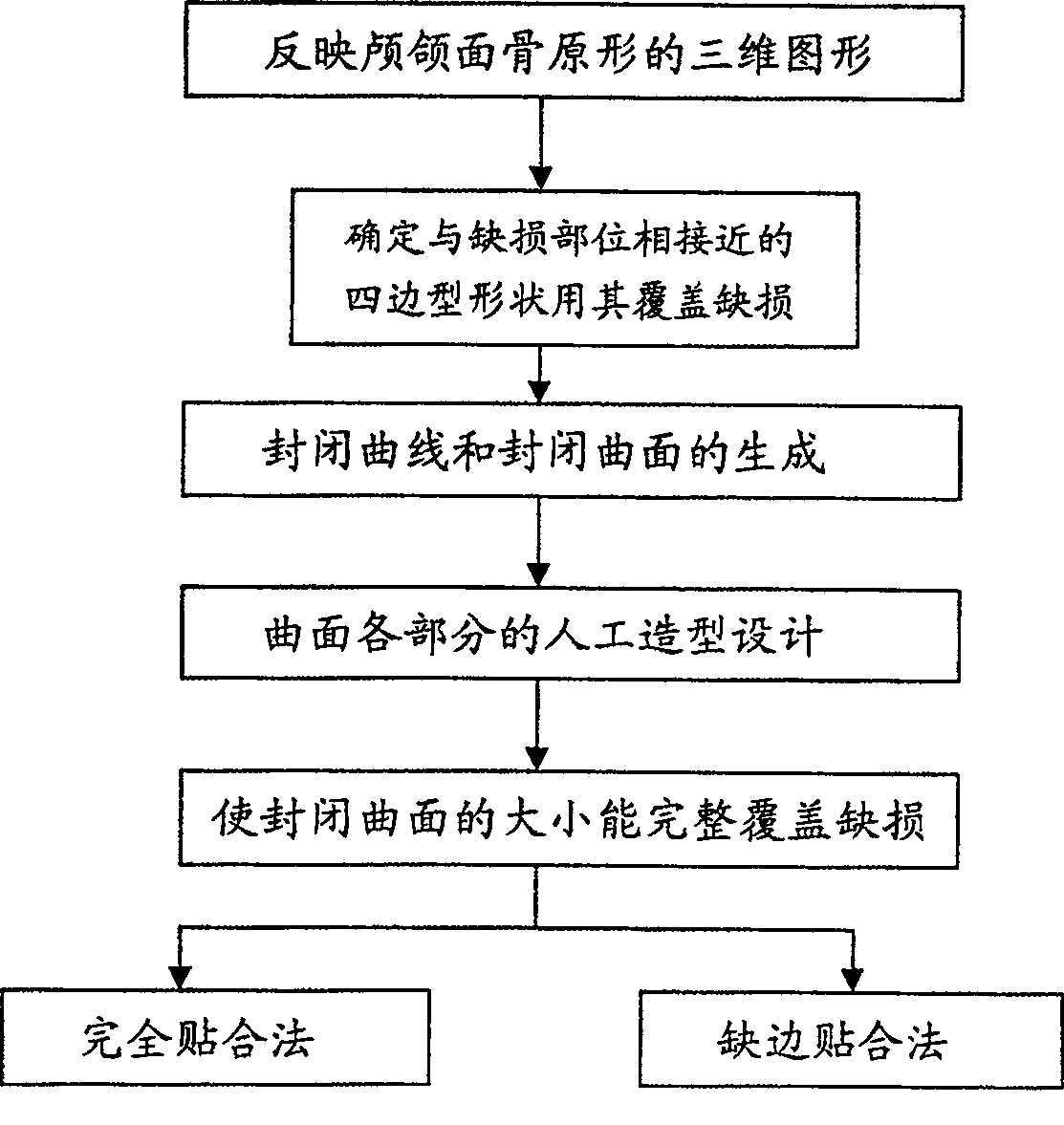

[0043] figure 1 The basic steps of the present invention are described: the first step, using CT tomography to obtain craniomaxillofacial bone image data of patients, the second step, computer three-dimensional reconstruction of craniomaxillofacial bone, the third step, computer-aided design of prosthesis, the second step The fourth step is rapid prototyping and processing of repair parts model, and the fifth step is investment precision casting.

[0044] Among them, the CT tomographic scan in the first step requires that the scanning slice thickness is ≤10 mm, and the reconstruction slice thickness is ≤2 mm, preferably 1.5 mm. In this way, there are more than one hundred images for a craniomaxillofacial bone of more than ten centimeters data. Record the data in standard DICOM format and save it as a CD-ROM file.

[0045] Preferably, the above-mentioned image files a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com