Multiple closed loop soil-derived water-water heat pump system

A pump system and hydrothermal technology, applied in heat pumps, lighting and heating equipment, refrigeration components, etc., can solve the problems of high return water temperature of underground coupled heat exchangers, reducing system refrigeration capacity and reliability, and reducing refrigeration efficiency, etc. Achieve the effect of improving energy efficiency and reliability, simple and easy control, and improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

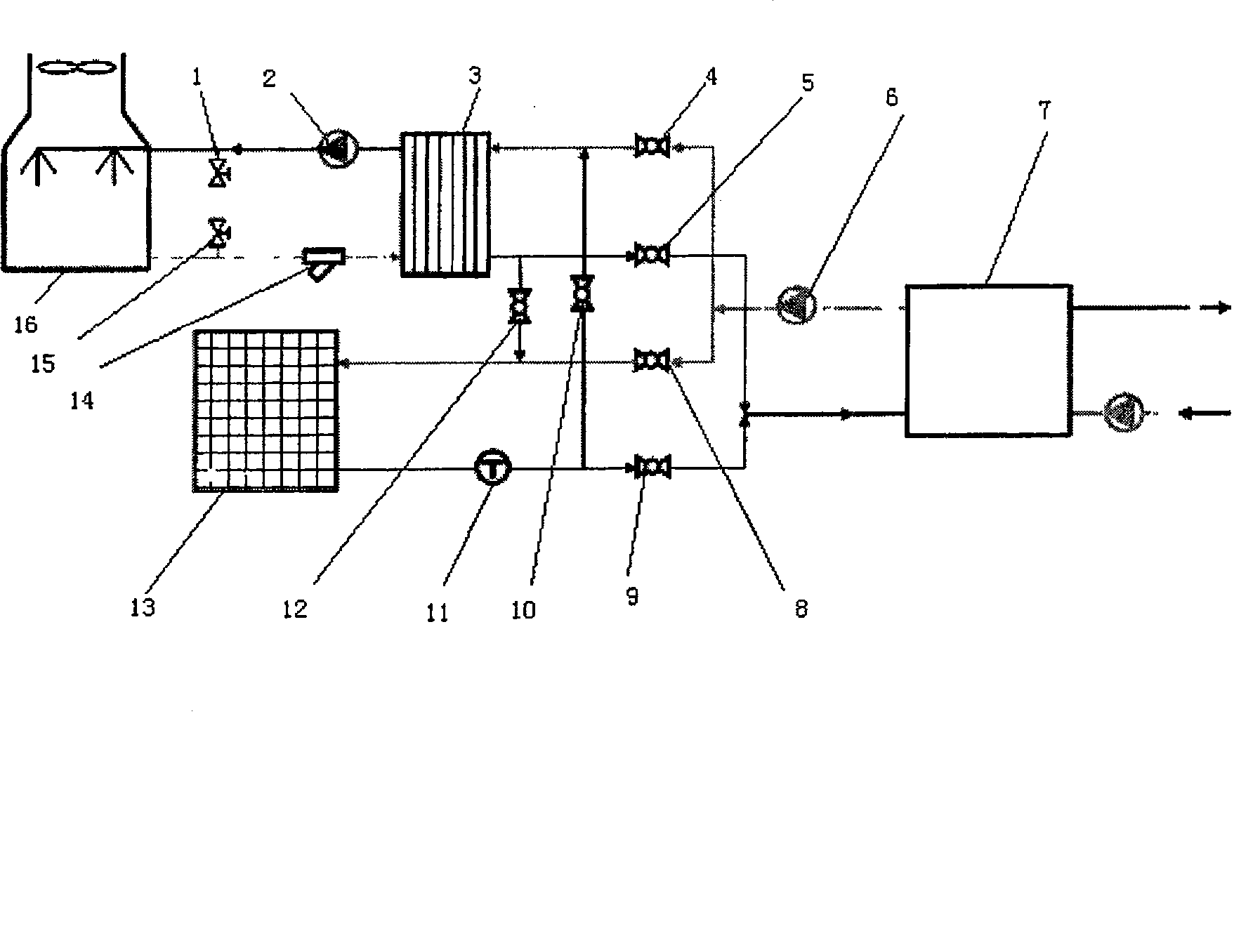

[0013] Referring to accompanying drawing 1, the outlet of the source side of the water-water heat pump 7 is connected with the first circulating water pump 6, and the water-water heat pump 7 connects with the first valve 8, the underground coupling heat exchanger 13, and the second valve 9 through the first circulating water pump 6 The first source-side circuit is formed in series, the outlet pipe of the horizontal underground coupling heat exchanger 13 is provided with a temperature sensor 11, and the water-water heat pump 7 passes through the first circulating water pump 6, the third valve 4, the plate heat exchanger 3, and the fourth valve 5 The second source side circuit is formed in series, the other heat exchange end of the plate heat exchanger 3 is connected to the cooling tower 16 through the second circulating water pump 2, the inlet pipe of the cooling tower 16 is divided with a seventh ball valve 1 for drainage, and the outlet of the cooling tower 16 The eighth ball ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com