Gas-liquid conversion pressurizing cylinder

A gas-liquid conversion, booster cylinder technology, applied in the direction of fluid pressure converter, fluid pressure actuation device, fluid pressure actuation system components, etc., can solve the problem of large actual space, unable to complete long-term work, and not well utilized Spring characteristic booster cylinder remaining space and other issues, to achieve the effect of simple structure and small actual space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

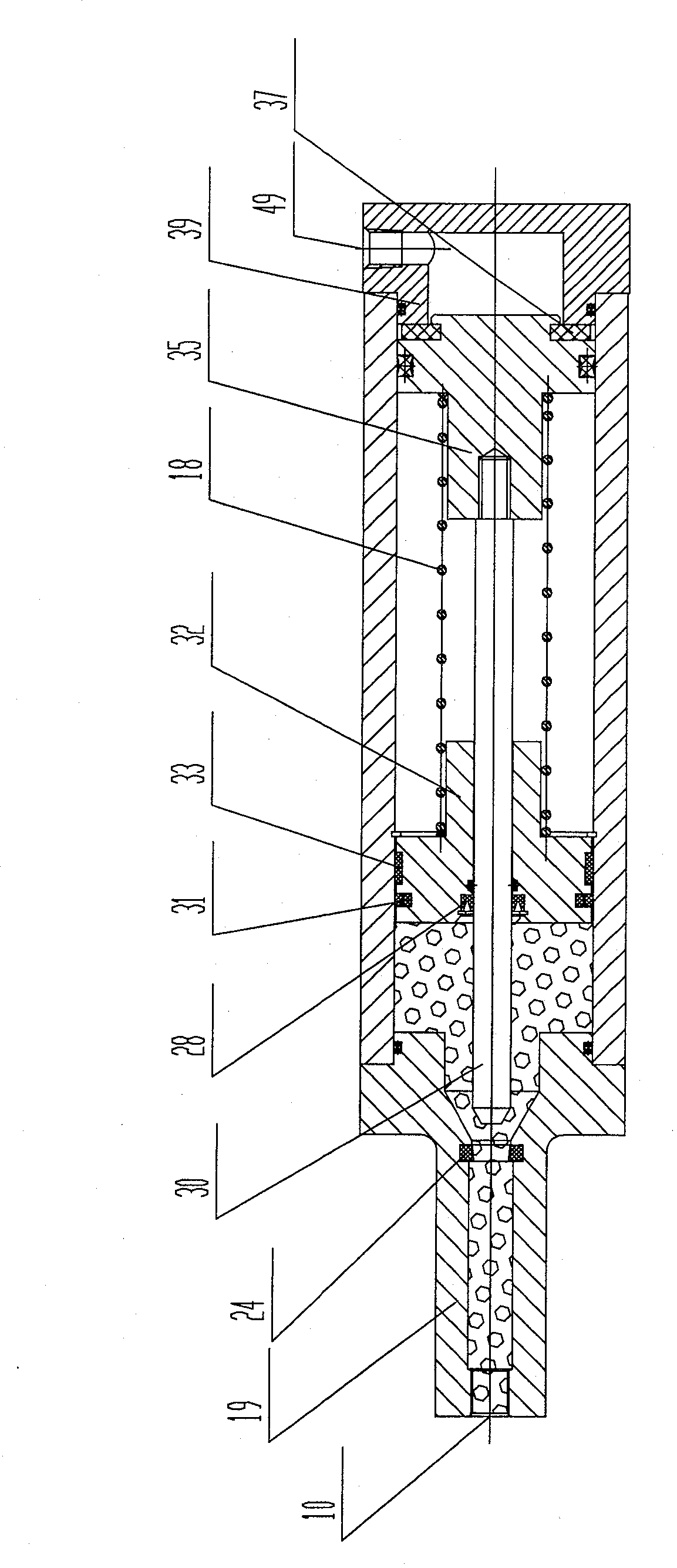

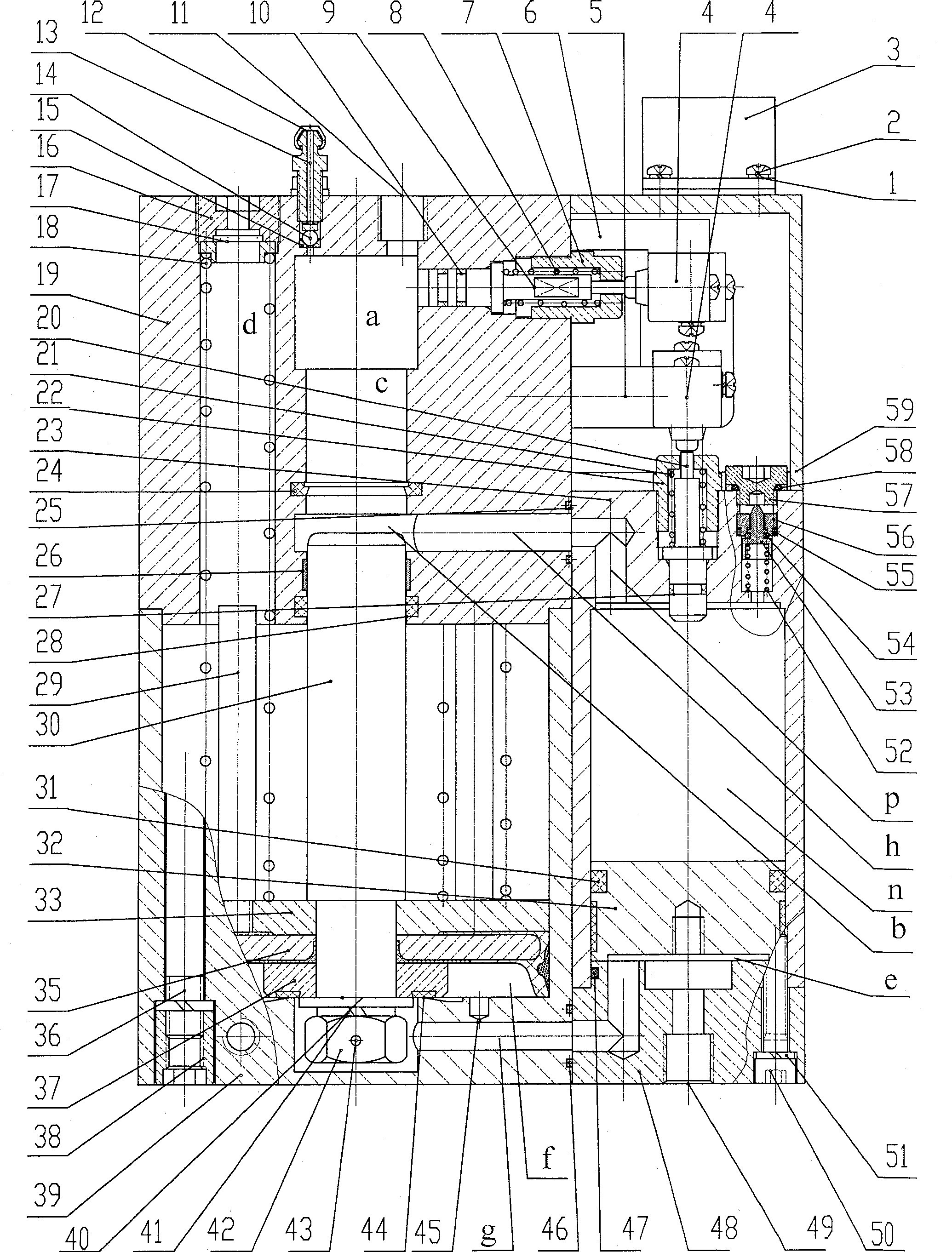

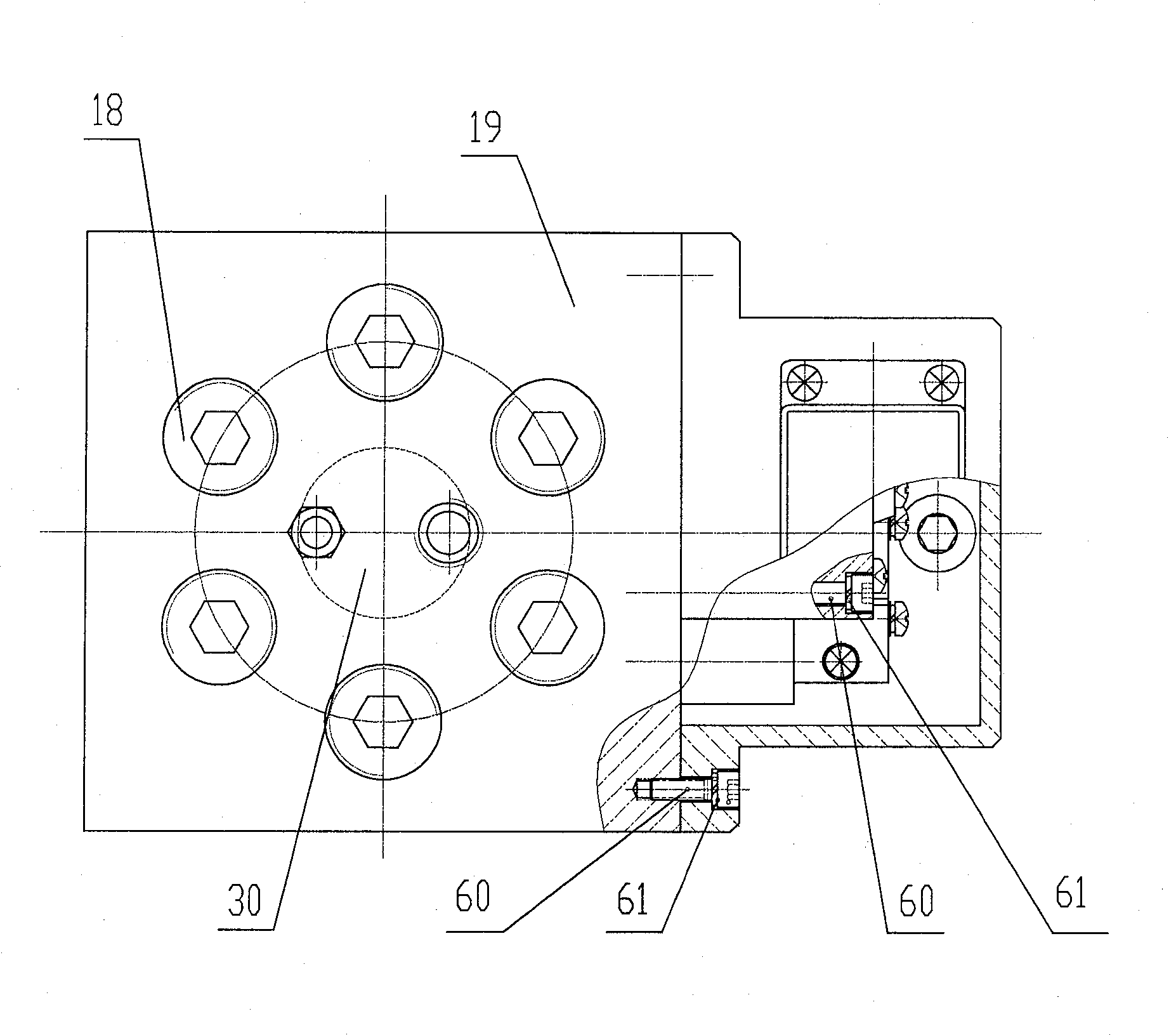

[0017] In the figure, spring washer 1, screw 2, junction box 3, micro switch 4, liquid level switch pad 5, compression nut 6, ejector rod seat 7, high pressure return spring 8, high pressure ejector rod 9, high pressure sealing ring 10, High pressure hydraulic oil outlet 11, dust cover 12, air release screw plug 13, steel ball 14, compression pad 15, screw sleeve 16, spring seat 17, air return spring 18, cylinder head 19, liquid level sending rod 20 , liquid level switch return spring 21, liquid level switch compression sleeve 22, oil storage cylinder 23, high pressure main oil seal 24, low pressure oil seal ring 25, ejector rod support ring 26, liquid level oil seal 27, low pressure main oil seal 28, guide rod 29. Piston rod 30, sealing ring 31, oil storage piston 32, pressure plate 33, piston 35, stud bolt 36, compression gasket 37, inner hexagonal round nut 38, cylinder body 39, flat washer 40, spring washer 41 , nut 42, cotter pin 43, speed switching port 44, throttle port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com