Convective microwave oven

A technology for microwave ovens and furnace bodies, which is used in heating methods, household stoves/stoves, and household heating, etc., can solve problems such as large installation space, increase transportation costs, and increase workload, so as to avoid damage to components and save installation. Process, the effect of shortening the length of the front and back

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

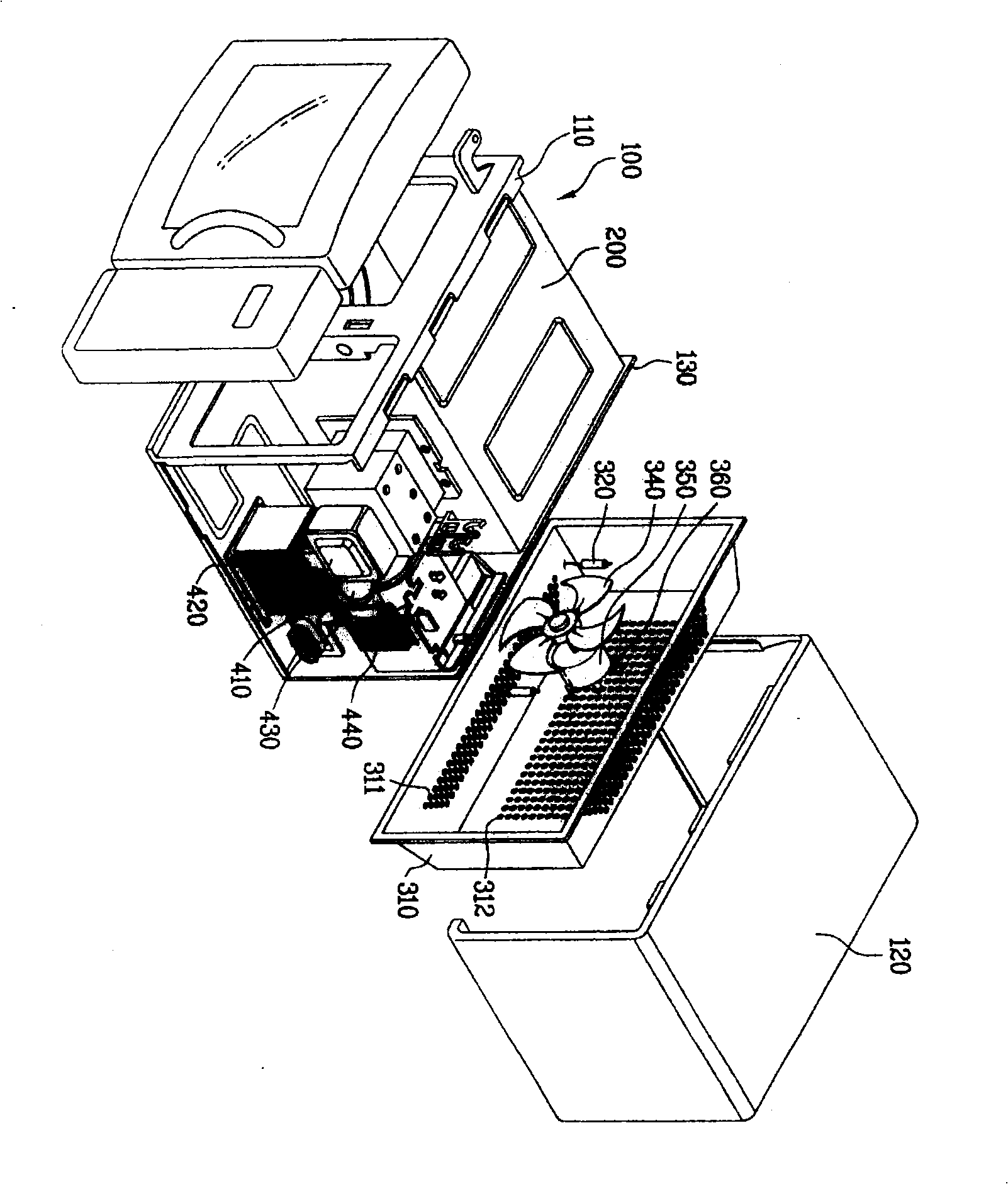

[0029] Below, refer to the attached image 3 , 4 Embodiments of the convection microwave oven of the present invention will be described in detail.

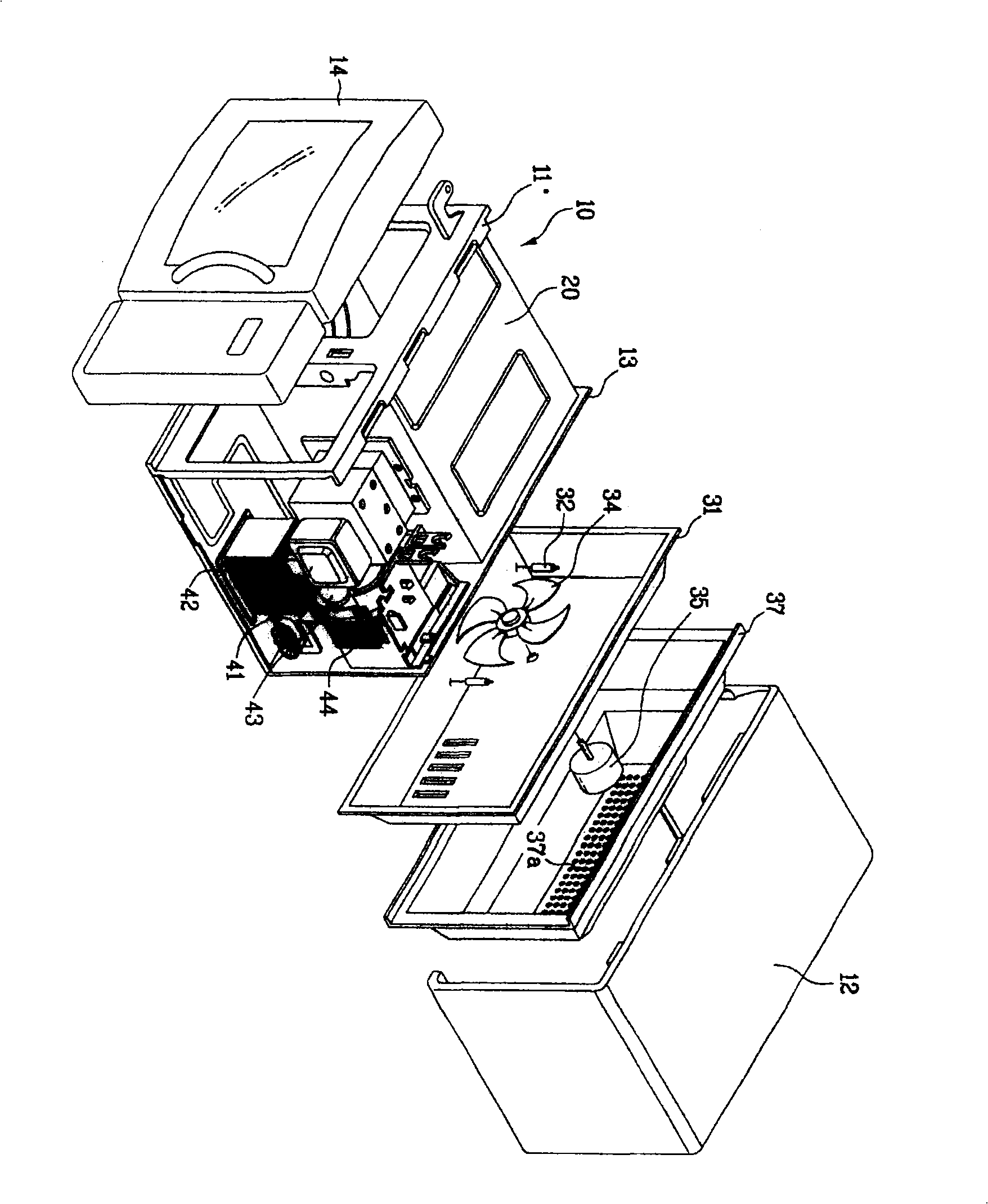

[0030] First, if image 3 and Figure 4 As shown, the structure of the convection microwave oven in the embodiment of the present invention includes: a furnace body 100 , a cavity 200 , a convection box 310 , a convection box motor 350 , a convection fan 340 and a convection heater 320 .

[0031] The furnace body 100 forming the appearance of the microwave oven includes: a front panel 110 , a shell 120 forming the two sides and a top structure, and a rear panel 130 forming the rear structure.

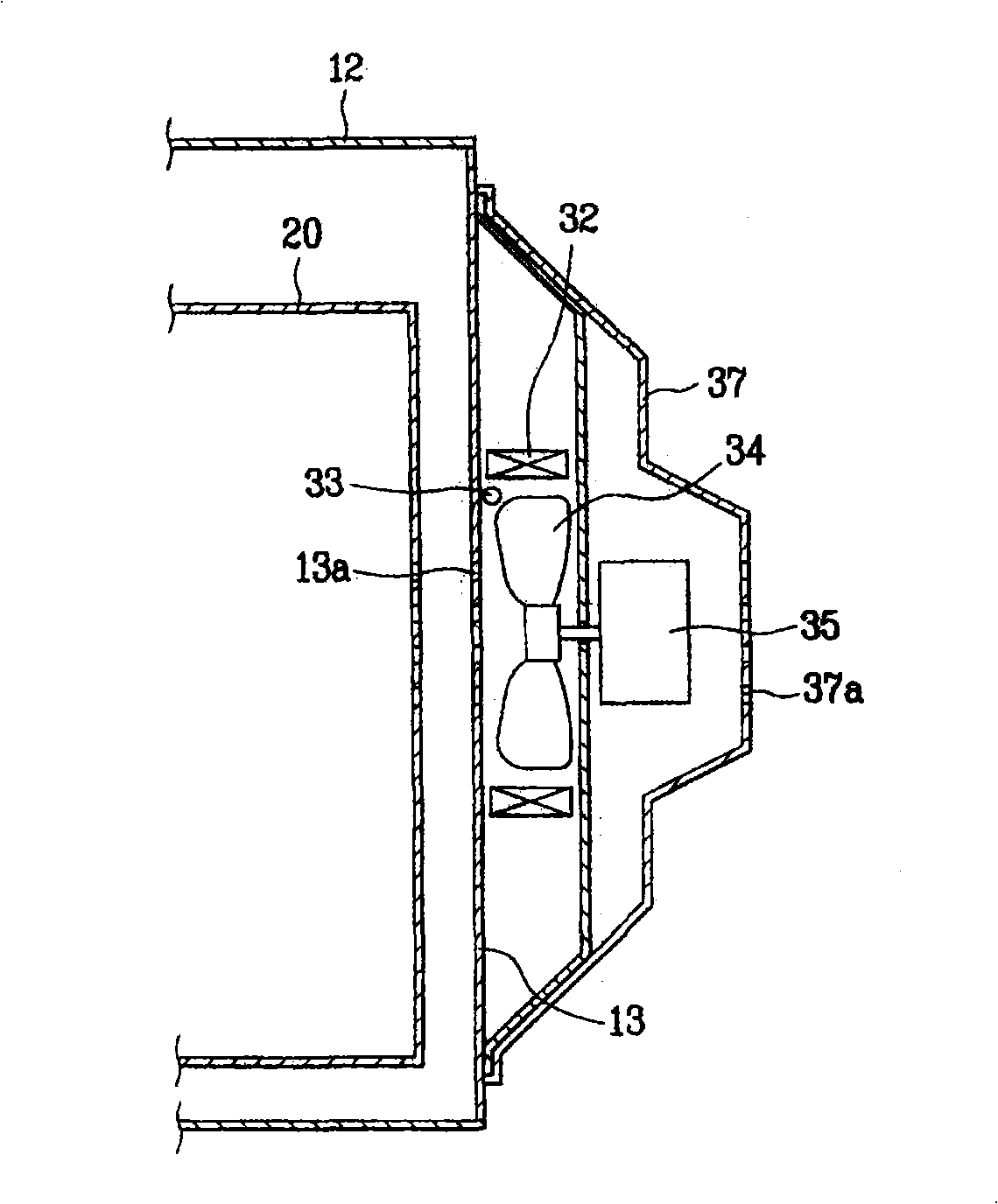

[0032] A plurality of through holes 131 communicating with the heating chamber in the inner space of the cavity 200 are provided on the rear panel 130 . Certainly, a plurality of through holes 201 are also provided on the back of the cavity 200 .

[0033] The convection box 310 has a certain space inside while surrounding the forming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com