The fixture for making the solid capacitor and use thereof

A technology for solid capacitors and fixtures, applied in the field of fixtures, can solve the problems of decreased yield, non-reusable metal strips, decreased capacitor characteristics, etc., and achieves the effects of reducing production costs, ensuring safety, and avoiding electrical shocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

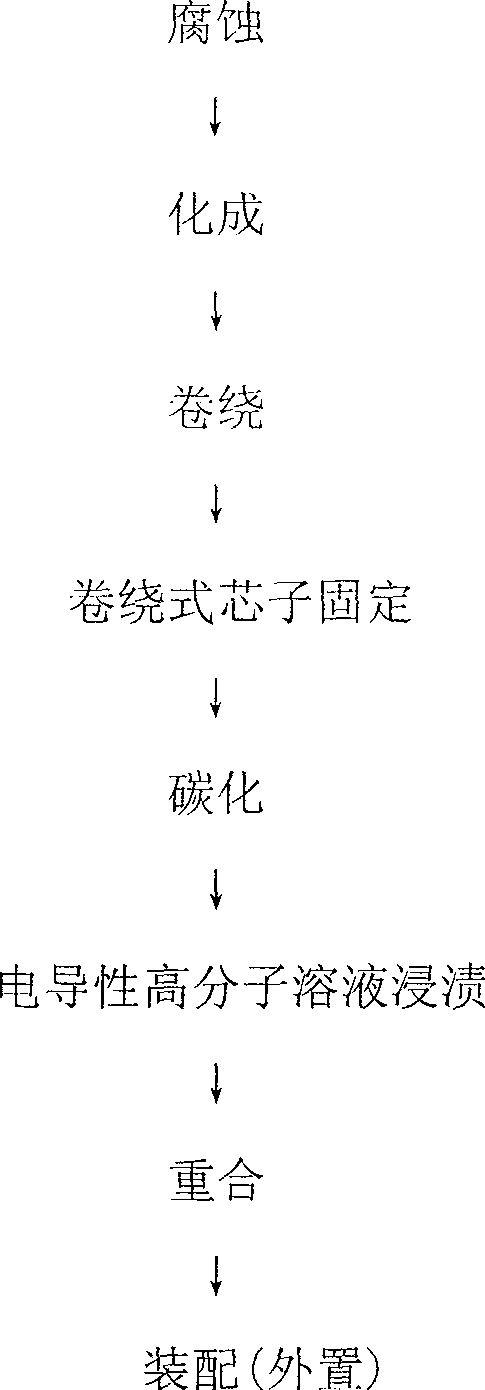

Method used

Image

Examples

Embodiment Construction

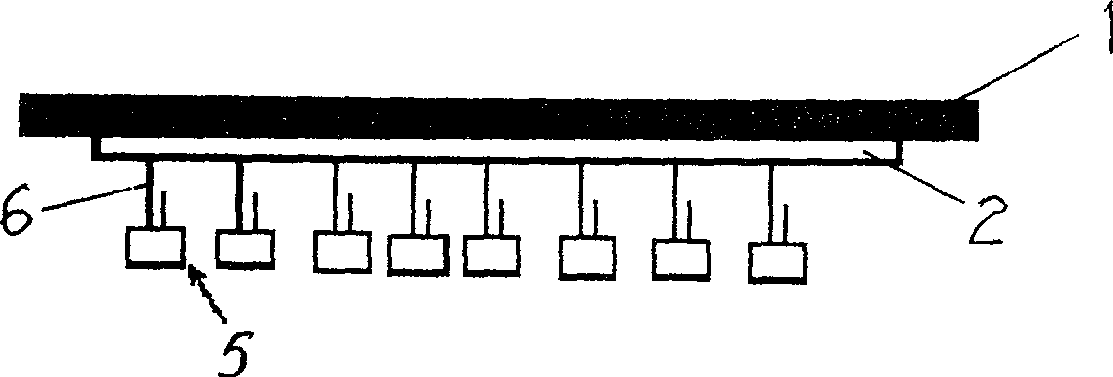

[0015] see Figure 4 , Figure 5 As shown, the embodiment of the present invention is composed of a metal belt 1, an electrode lead-out wire guide plate 2 and several magnetic objects 3, the metal belt 1 and the electrode lead-out wire guide plate 2 are fixed together, and several magnetic objects 3 are arranged on the electrode In the lead-out wire guide plate 2, a tapered hole 4 is opened on the electrode lead-out wire guide plate 2 corresponding to the position of each magnetic object 3, and the magnetic object 3 is a magnet in this embodiment.

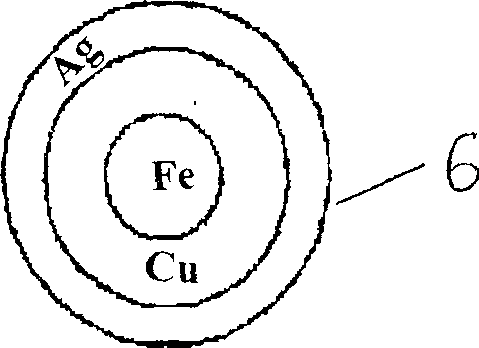

[0016] see figure 2 As shown, the middle of the electrode lead-out wire 6 of the aluminum electrolytic winding type core 5 fixed by the present invention is an iron core (Fe), and the outer layer of the iron core is a copper layer (Cu) of more than about 20 μm, and the outer layer of the copper layer is about 3 μm For the above silver coating (Ag), the iron core not only needs to meet the strength of the electrode lead wire, but...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com