Jet type electrostatic spinning equipment capable of producing Nano fiber

A technology of electrospinning and nanofibers, which is applied in fiber processing, spinneret assemblies, textiles and papermaking, etc. It can solve problems such as difficulties, spinneret electric field interference, and inability to meet mass production and product applications. The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

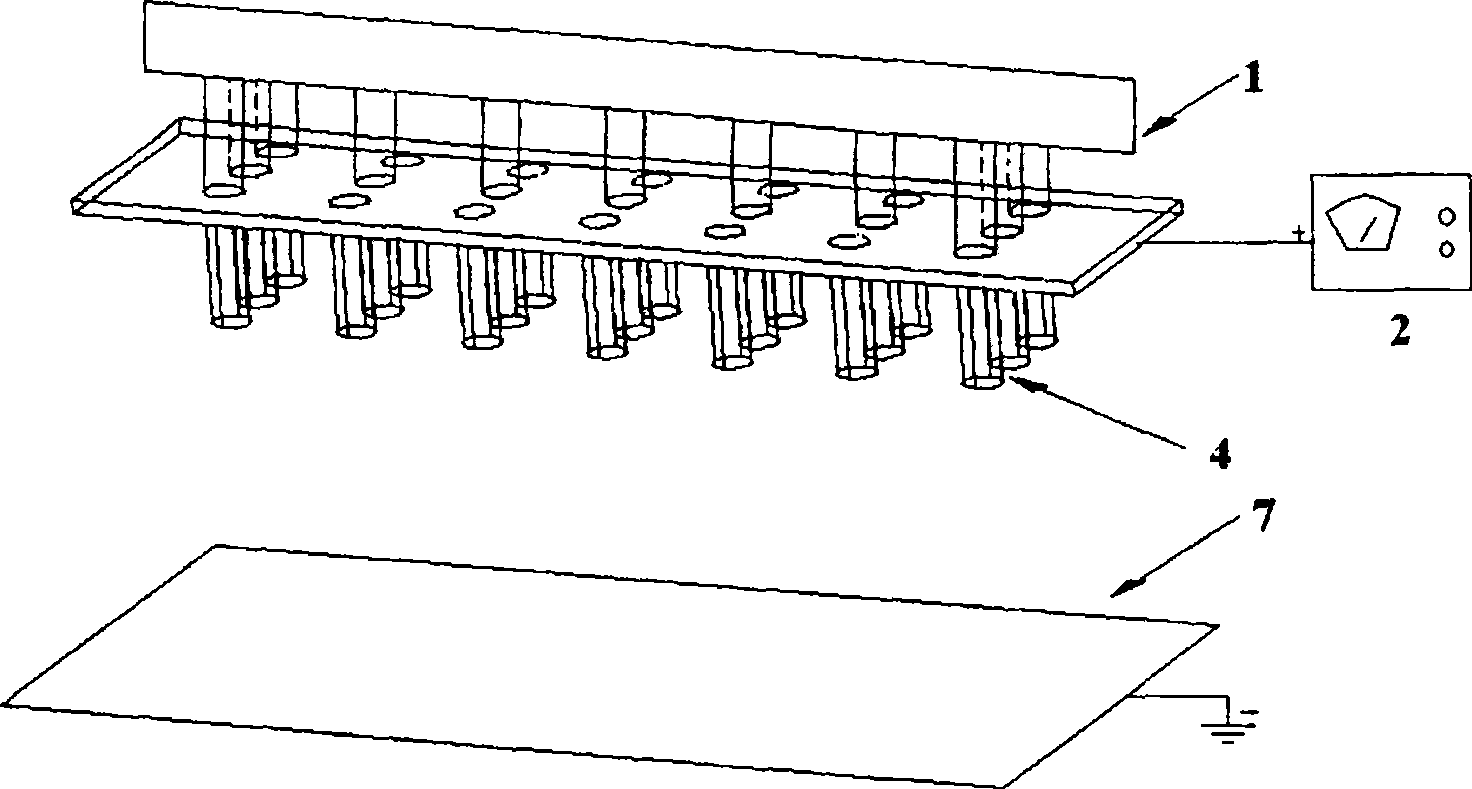

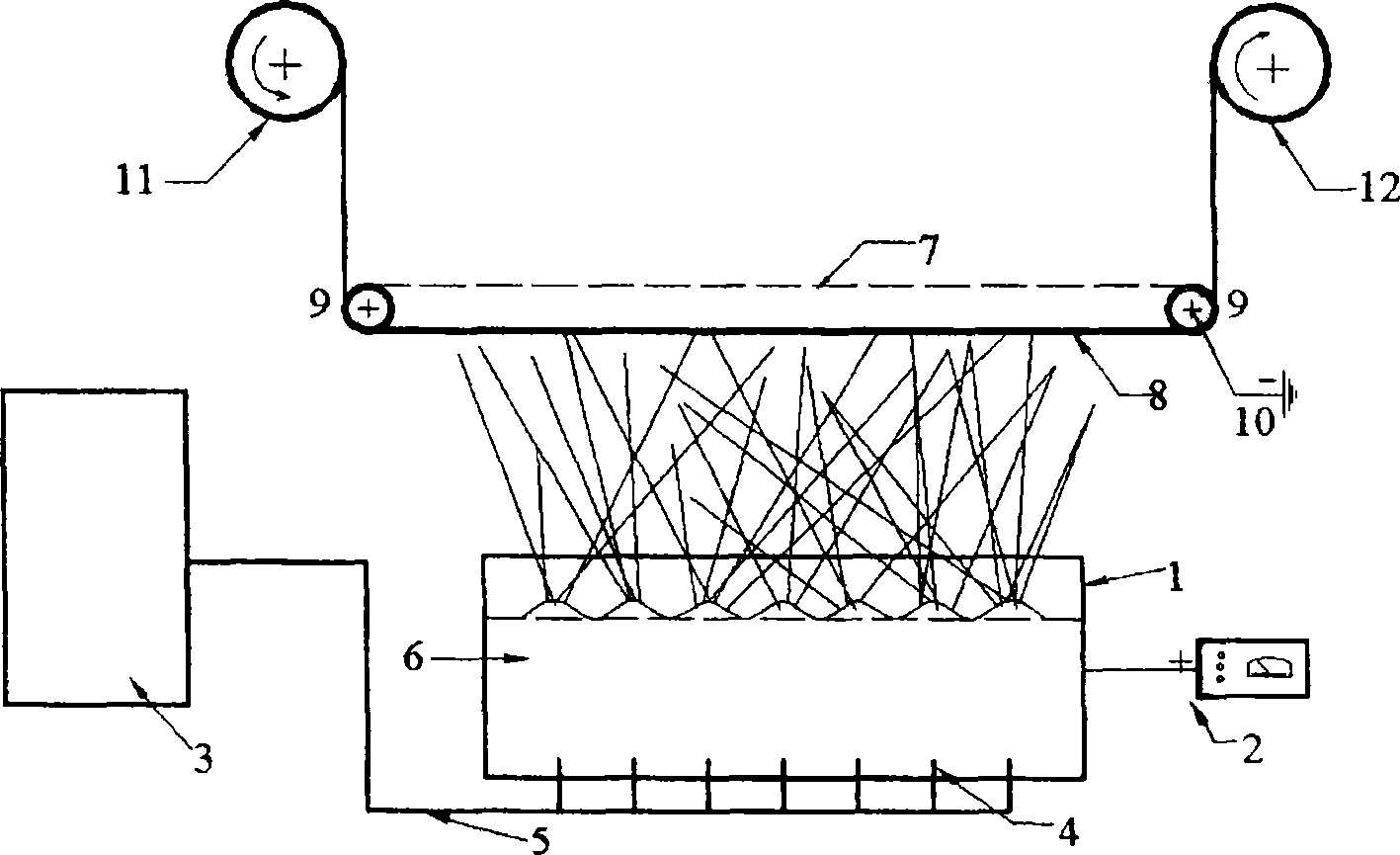

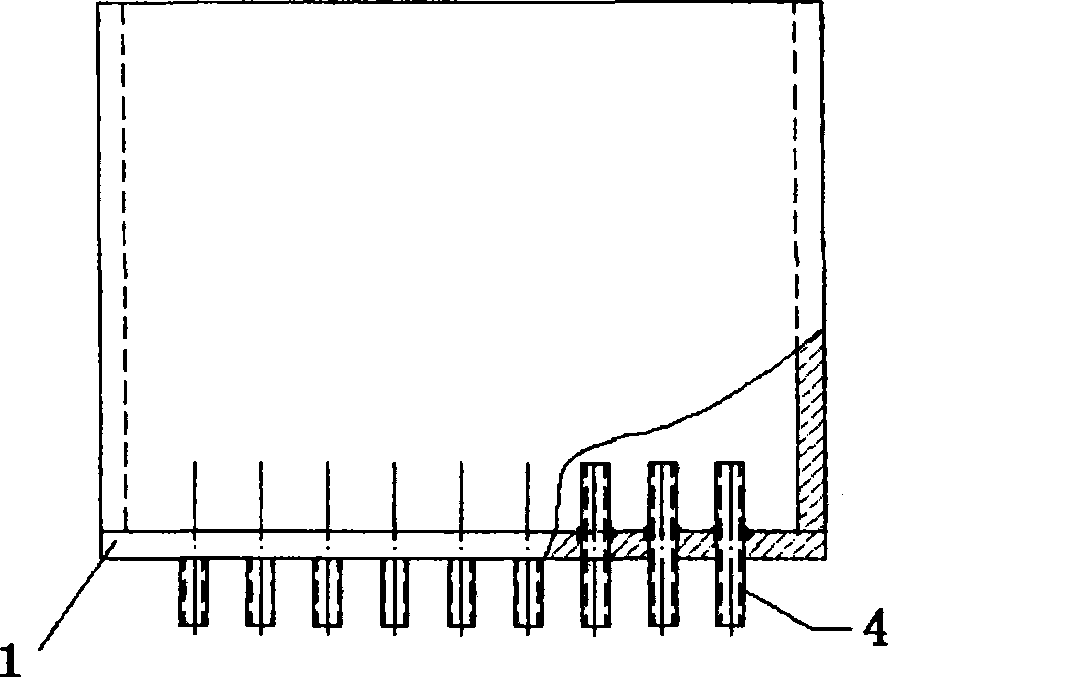

[0016] An air-jet electrospinning device that can be used to produce nanofibers, comprising a liquid storage tank 1, a high-voltage electrostatic generator 2, a nozzle 4, an air pump 3 and a receiving plate 7, the upper end of the liquid storage tank 1 is open, and the storage The bottom surface of the liquid pool 1 is provided with vertically upward nozzles 4 arranged in a matrix. The nozzles 4 are connected to the air pump 3 through the air guide tube 5, and the connection between the conduit and the air pump 3 is higher than the liquid level of the liquid storage pool 1. Connected with the high-voltage electrostatic generator 2, there is a transmission device and a receiving curtain 8 directly above the liquid storage tank 1, the transmission device is composed of a receiving plate 7 and a guide roller 9, and the receiving plate 7 is connected to the ground electrode 10 through the guide roller 9 One end of the receiving curtain 8 is connected to the unwinding roller shaft 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com