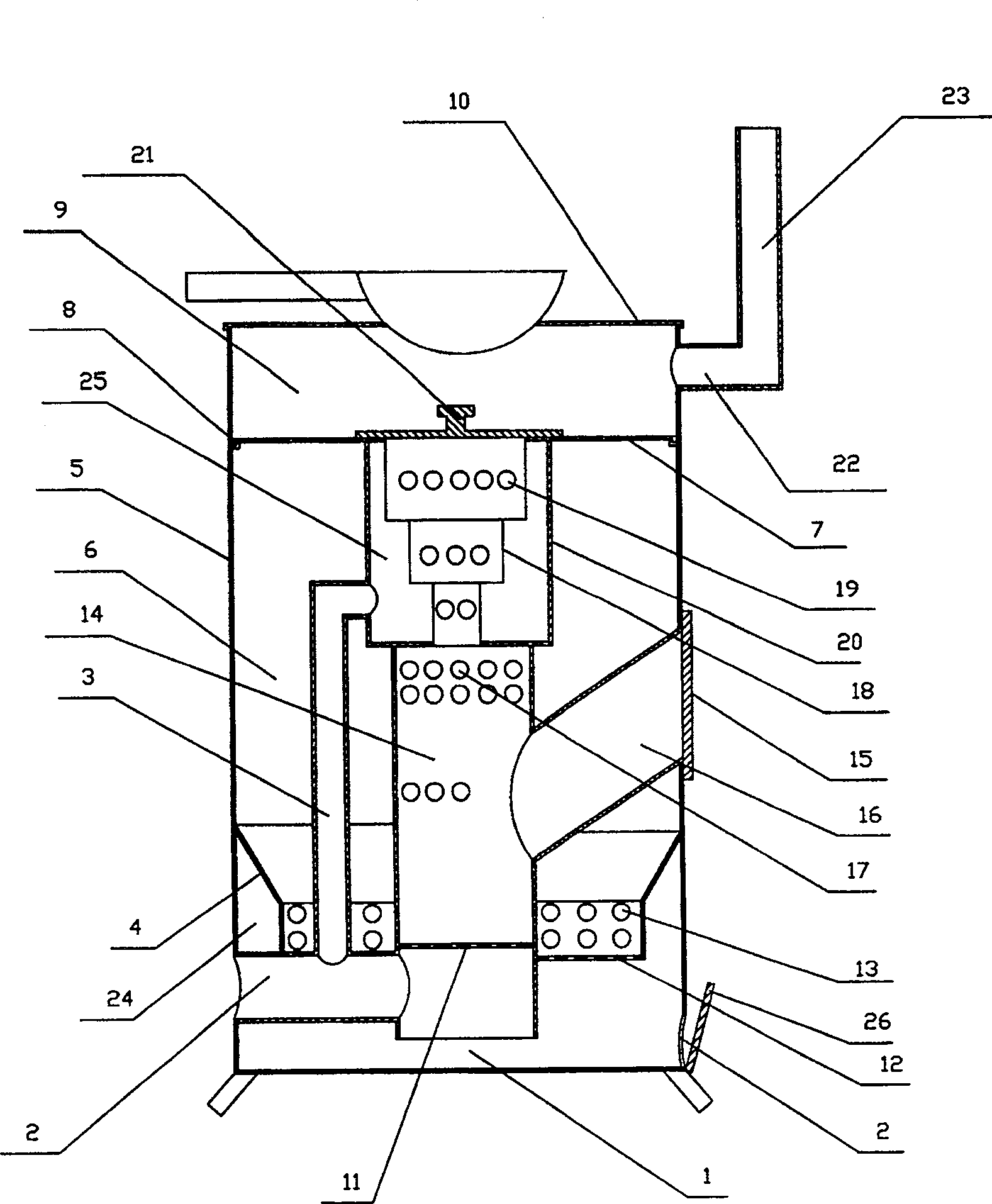

Integral compound gasification stove

A gasification furnace, an integrated technology, applied in the field of stoves for generating gas from biomass fuels, can solve the problems of certain requirements for the use of raw materials, inconvenient feeding, unstable combustion, etc., and achieves convenient operation, stable flame, and high performance. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] specific implementation plan

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] In the accompanying drawings, there is an oxidation combustion chamber 14 inside the gasification furnace 6, and the upper end of the oxidation combustion chamber 14 is connected with a multiple oxygen distributor 20. The multi-time oxygen distributor 20 has three cylindrical oxygen distribution plates 18 with different diameters. There are many evenly distributed oxygen supply holes 19 on the oxygen distribution plate 18. An oxygen supply ring 25 is formed, and the oxygen supply ring 25 communicates with the air inlet 2 through the multiple oxygen distribution pipe 3 , and the multiple oxygen distribution device 20 is also equipped with a fire sealing cover 21 . There are a plurality of gas holes 17 at different heights on the upper part of the chamber wall of the oxidation combustion chamber 14, and the side is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com