Gas kitchen range and gas generator supplying gas to the same

A gas stove and gas technology, which is applied to coke ovens, biofuels, household stoves/stoves, etc., can solve the problems that the firepower is difficult to achieve the expected effect, the purification effect is not ideal, the gas stove pipeline is blocked, etc. Easy to clean and improve the effect of firepower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

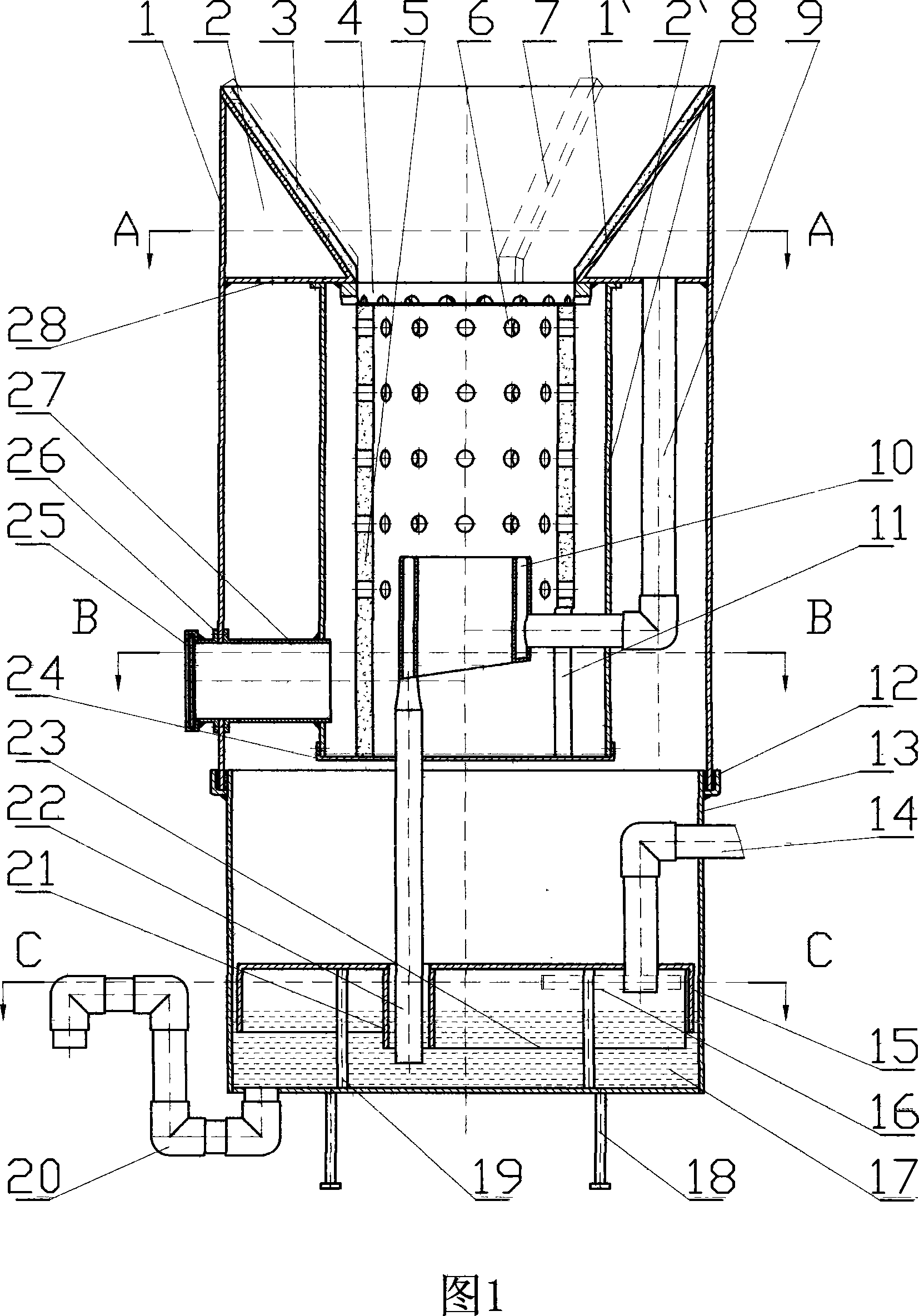

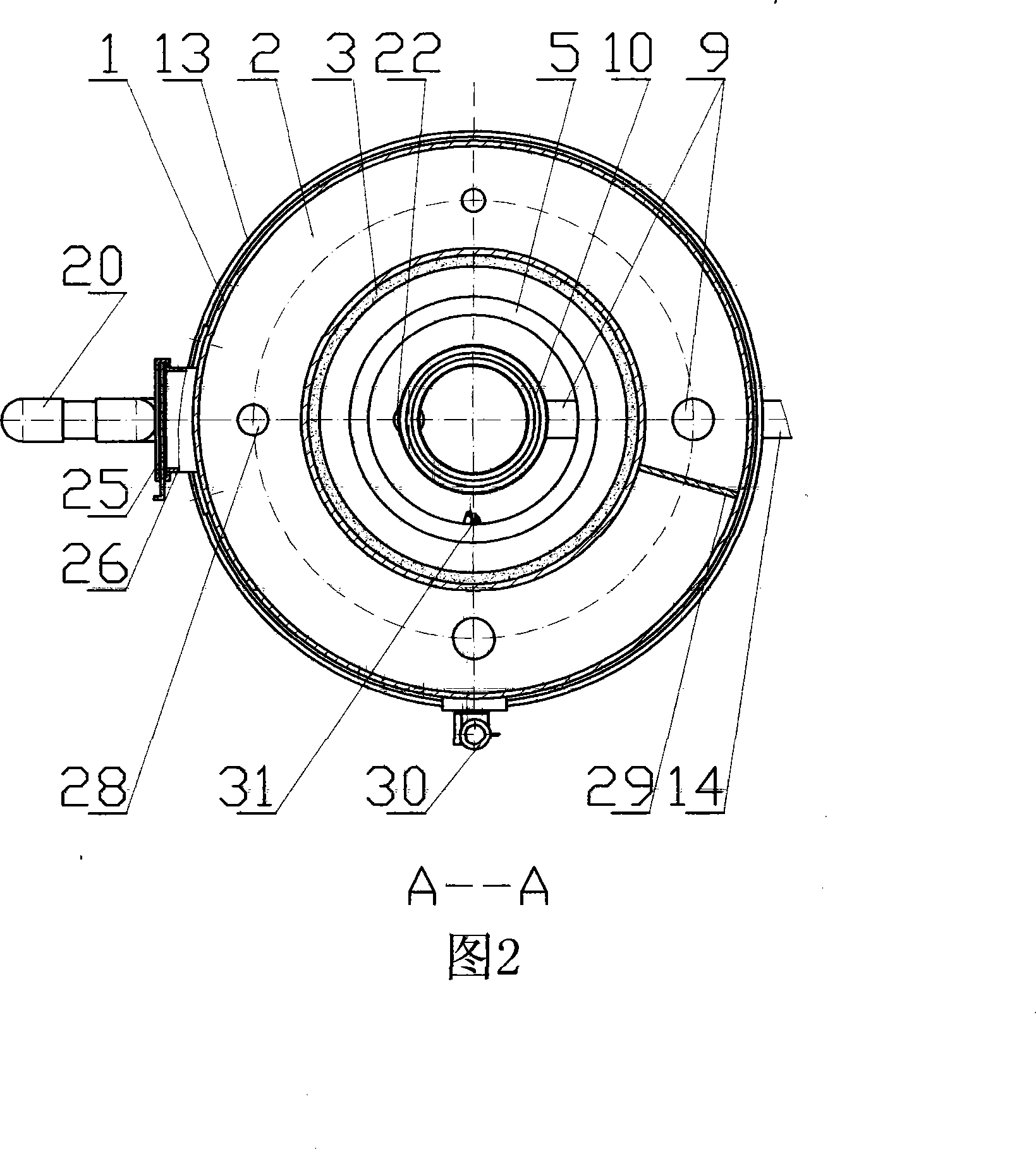

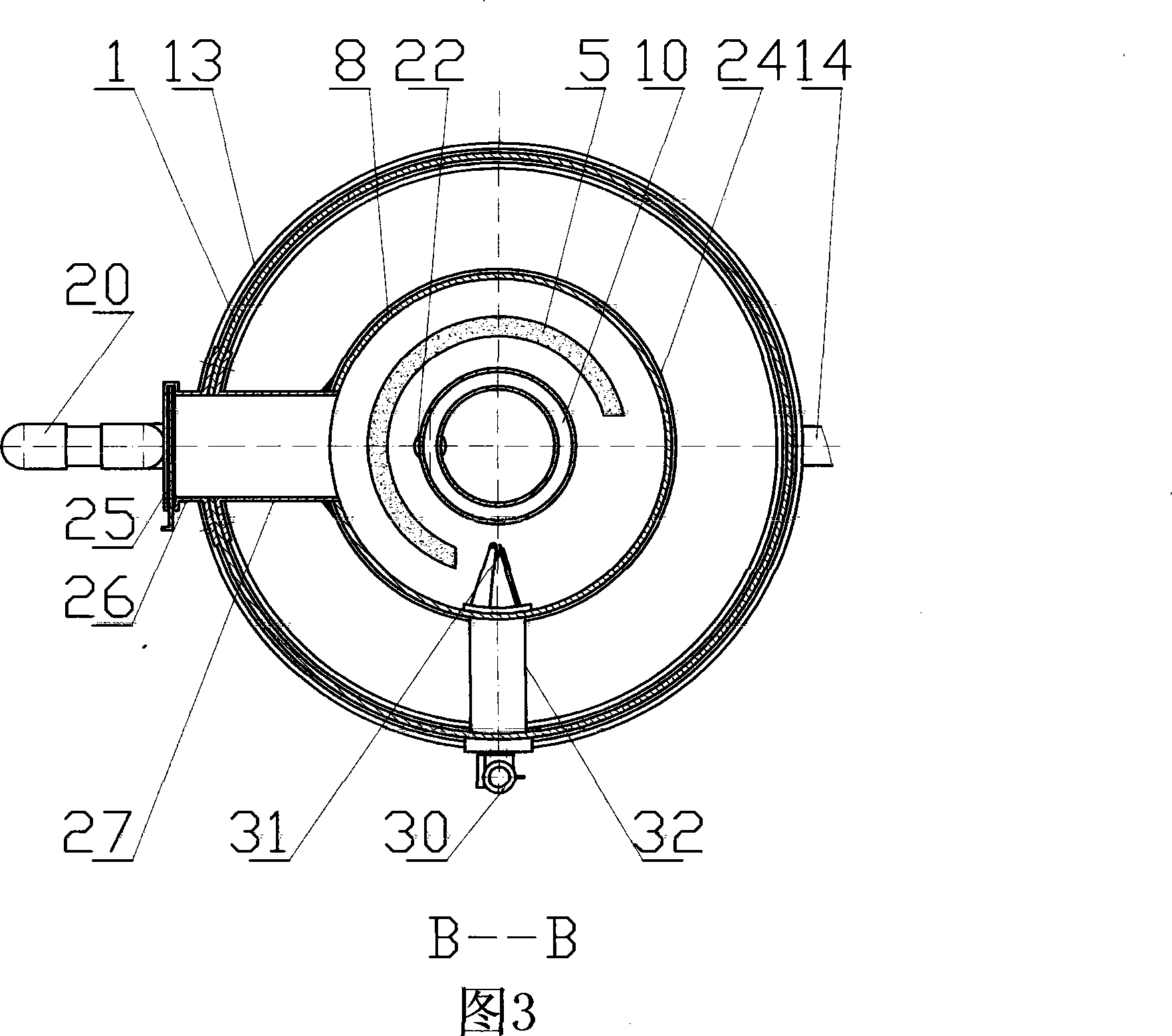

[0029] The gas stove of the present invention is composed of a stove body 1, a stove body 5, a pan bar 7, a hot and cold gas isolation cover 8, a hot gas guide pipe 9, a gas uniform distributor 10, a gas purification cylinder 13, an air intake pipe 14, a gas purification Disc 15, stove foot 18, tar discharge pipe 20, tar guide pipe 22, outer air inlet cylinder 26 and inner air inlet cylinder 27 and ignition device 30 constitute.

[0030] The stove body 1 is a cylinder, and its upper end forms an inner conical gas preheating cavity 2 with a triangular inner cavity section with the ring plate 2` and the conical cylinder 1`. The upper conical surface of the conical cylinder 1` is covered with Refractory layer kitchen range wall 3, the top device of kitchen range wall 3 puts pot bar 7, is used for shelving cooking all. There are four air inlet holes 28 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com