Novel high carbon high wolfram fast steel rolling roller and preparation process thereof

A high-speed steel and high-tungsten technology, which is applied in the field of new high-carbon high-tungsten high-speed steel rolls and their preparation, can solve problems such as shedding and increased cost of rolls, and achieve the effects of increasing density and hardness, reducing additives, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

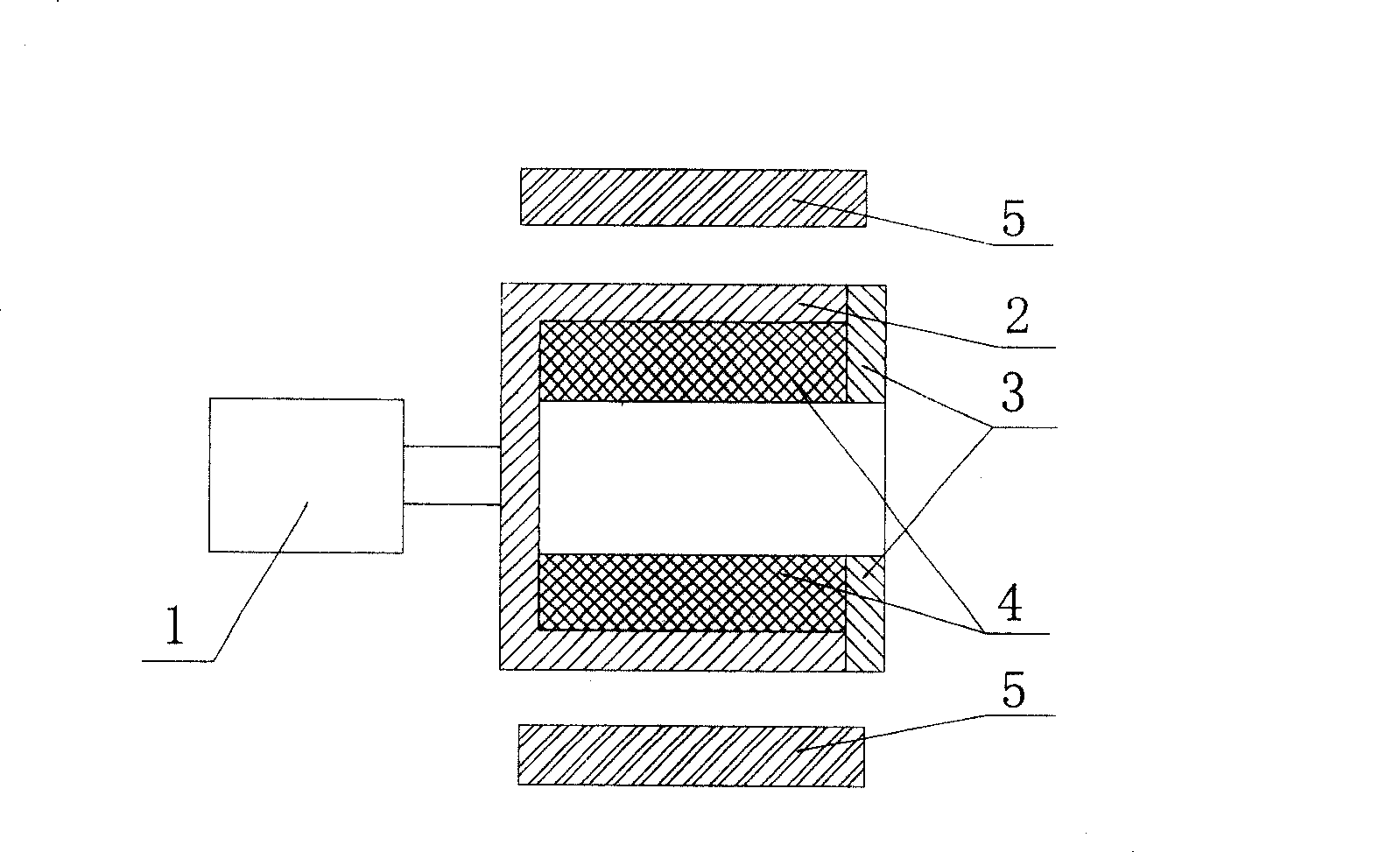

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] The high-carbon high-tungsten high-speed steel roll of this embodiment is melted by a medium-frequency induction furnace, and contains the following elements by weight percentage: 2.4% carbon, 15.0% tungsten, 3.5% vanadium, 2.0% molybdenum, 6.0% chromium, silicon<1.2%, manganese <1.2%, the rest is iron element and unavoidable impurities, sulfur <0.04% and phosphorus <0.04% are controlled in impurities.

[0016] Carbon is used to obtain a certain amount of carbide hard phase, improve the wear resistance of the roll, and part of the carbon dissolved in the matrix can also improve the hardenability; if the amount is too much, the material is brittle, the thermal cracking resistance is poor, and casting cracks are easy to occur , Therefore, its content is controlled at 2.0-3.0%. Tungsten mainly exists in MC composite carbides and M 2 In C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com