Liquid fuel for industrial boiler by using diesel oil slurry of powdered coal as raw material, and preparation method

A technology for industrial boilers and liquid fuels, which is used in liquid carbon-containing fuels, petroleum industry, fuels, etc. to achieve the effects of good fluidity, lower costs, and improved coal utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The selected raw material composition distribution ratio (quality) of the present invention is pulverized coal: 50-60%, the best quality: 53%, diesel oil: 5-10%, the best quality: 5%, oil slurry: 30-40%, the best Best quality: 40%, anionic and nonionic surfactants 0.5-3.0%, best quality: 2%.

[0017] Prepare liquid fuel method of the present invention by above-mentioned each component is:

[0018] Put the oil slurry dispersant and diesel oil into the container tank according to the given ratio at normal temperature and pressure, and blend evenly, then add coal powder ground to a certain particle size into the container tank in batches, and then fully stir until The product can be made when the viscosity is 1000-1800MPa·S in the vortex state.

[0019] The dispersant is composed of two compounds, that is, an anionic surfactant and a nonionic surfactant, and the volume fractions of the two compounds are 70-92% and 8-30% or 80-97% and 3-20% respectively.

[0020] The dies...

Embodiment 2

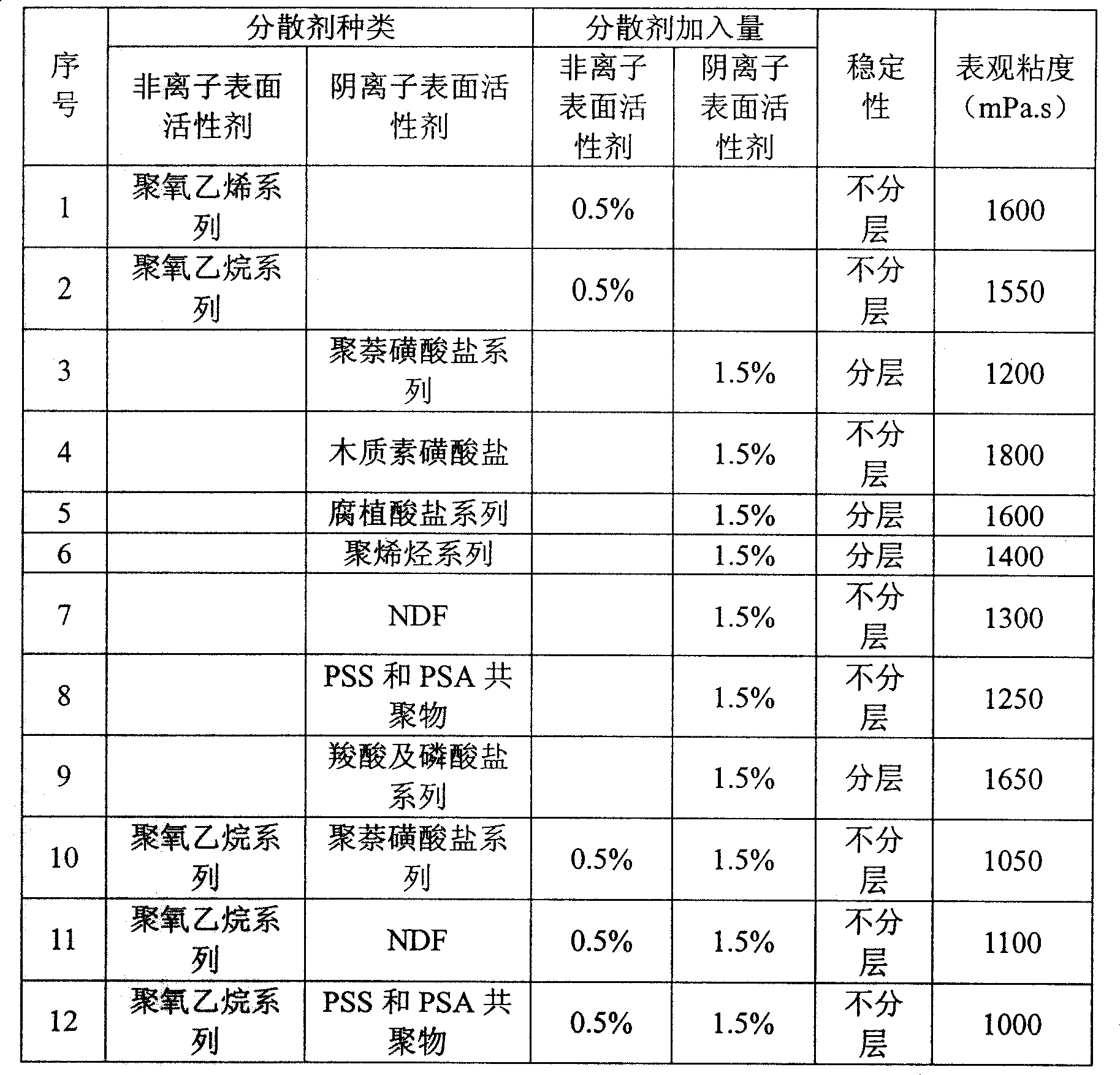

[0022] 1. Screening of dispersant types

[0023] The main function of the dispersant is to change the lipophilicity of the surface of coal particles, enhance the electrostatic repulsion, promote the uniform dispersion of coal particles in the composite system of oil slurry and diesel oil, prevent coal particles from agglomerating, and Characteristics Select the following anionic surfactants and nonionic surfactants (cationic surfactants are rarely used as dispersants) as the main research objects. 55% of coal powder (200 mesh), 35% of oil slurry, 8% of diesel oil, and 2% of dispersant are fully mixed to a slurry state at room temperature. The specific results of the apparent viscosity and stability of the test system are as follows:

[0024]

[0025] Note: The stability in the table refers to the product system standing at room temperature for 48 hours to see if it is delaminated

[0026] It can be seen from the results that non-ionic surfactants have good stability while ...

Embodiment 3

[0040] 6. Preparation method:

[0041] Blend the oil slurry, dispersant and diesel oil according to the given ratio at normal temperature and pressure. After blending evenly under closed conditions, add coal powder ground to a certain particle size in batches, and stir until the vortex is closed. Can.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com