Transmission mechanism of curtain slice braiding machine

A transmission mechanism and weaving machine technology, applied in mechanical equipment, sugarcane machining, etc., can solve the problems of large equipment occupation, long transmission mechanism, low processing efficiency, etc., and achieve the effect of increasing speed, compact structure and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

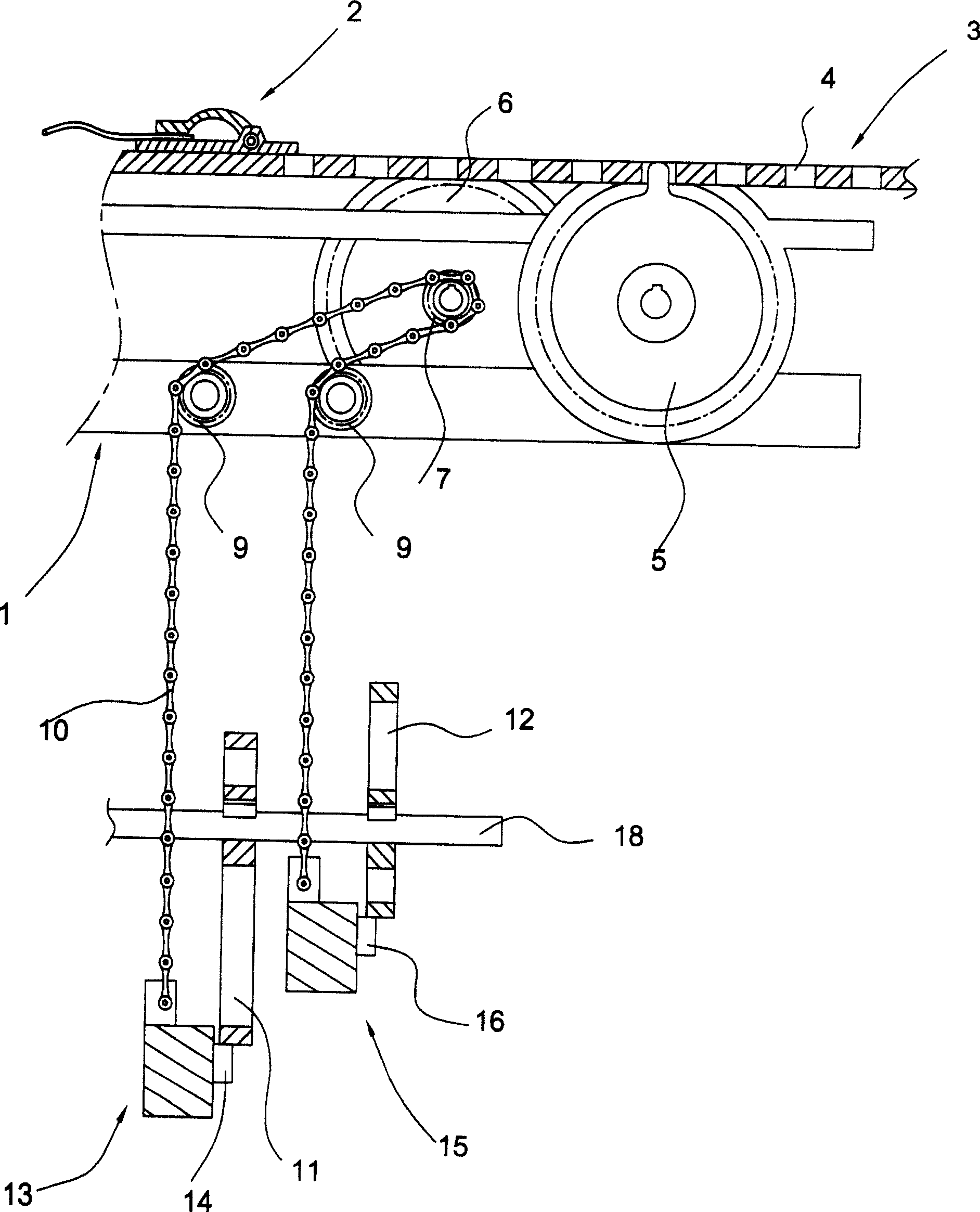

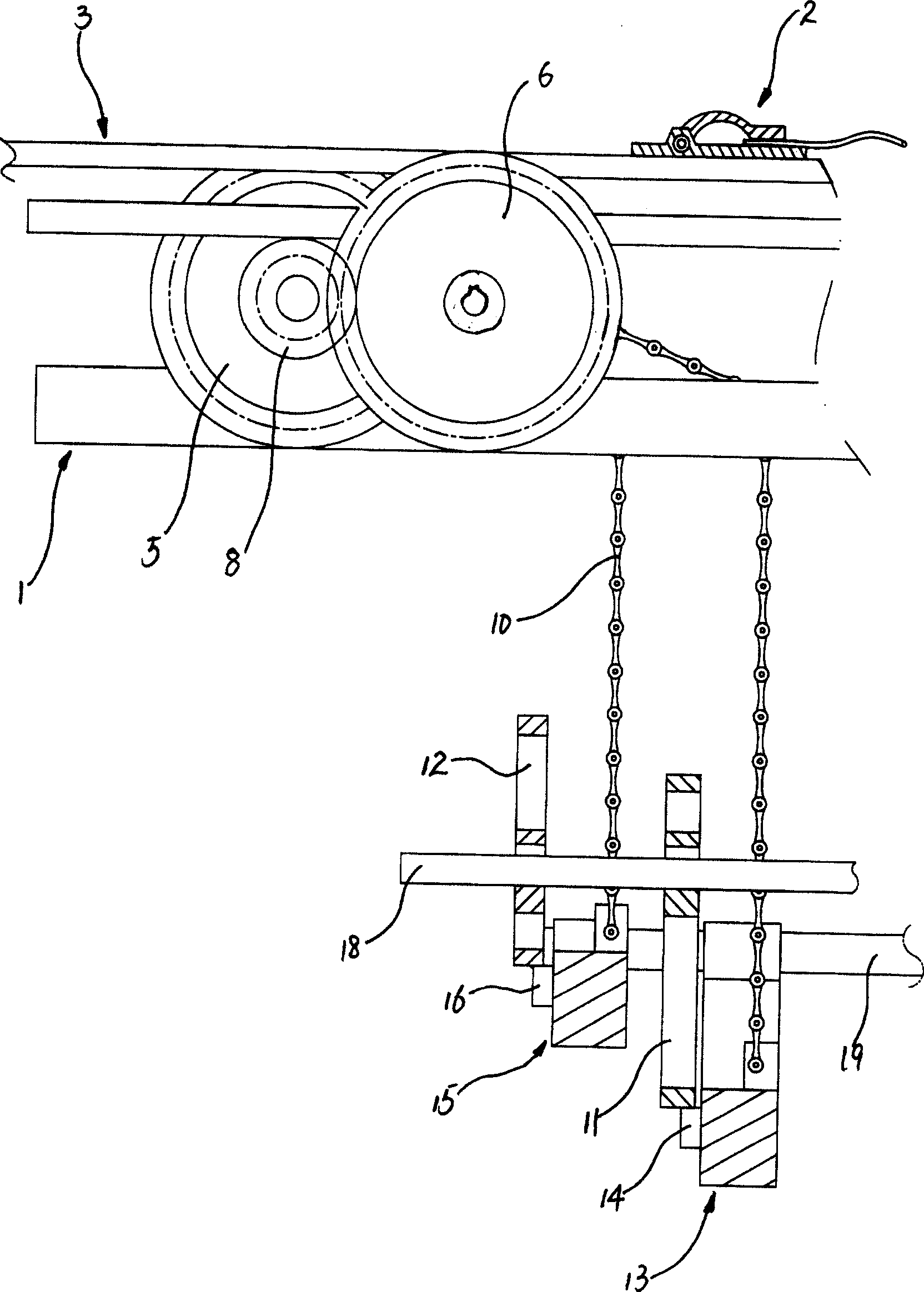

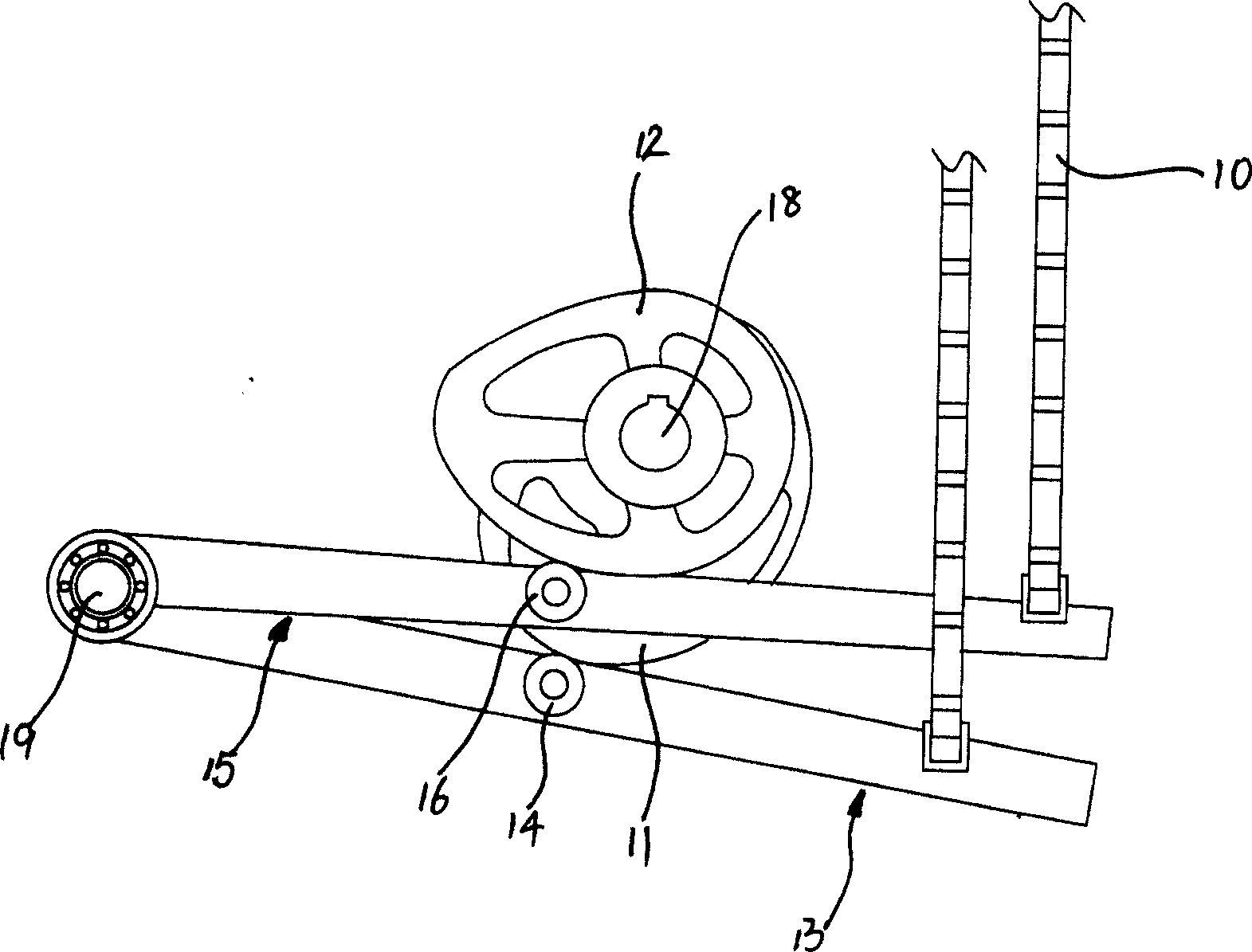

[0017] See attached figure 1 to attach image 3 , a transmission mechanism of a curtain knitting machine, comprising a weaving shuttle 2 that reciprocates relative to a frame 1, a belt 3 fixedly connected to the weaving shuttle 2, and a belt 3 connected to the belt 3 in phase transmission The first gear 5 has a plurality of key slots 4 on the strap 3 , and the teeth of the first gear 5 are sequentially inserted into the key slots 4 to move the strap 3 . Therefore, when the first gear 5 rotates clockwise or counterclockwise, it can drive the belt 3 and the weaving shuttle 2 to reciprocate linearly. Thereby the weaving thread on the weaving shuttle 2 can reciprocate and enter the shed opening for weaving.

[0018] The transmission mechanism also includes a power shaft 18 fixedly connected to the rotor part of the motor, the power shaft 18 is rotatably connected to the frame 1, and the first cam 11 is coaxially fixed on the power shaft 18 and the second cam 12.

[0019] The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com