Multicolored organic LED

A light-emitting diode, organic technology, applied in the direction of light-emitting materials, electrical components, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

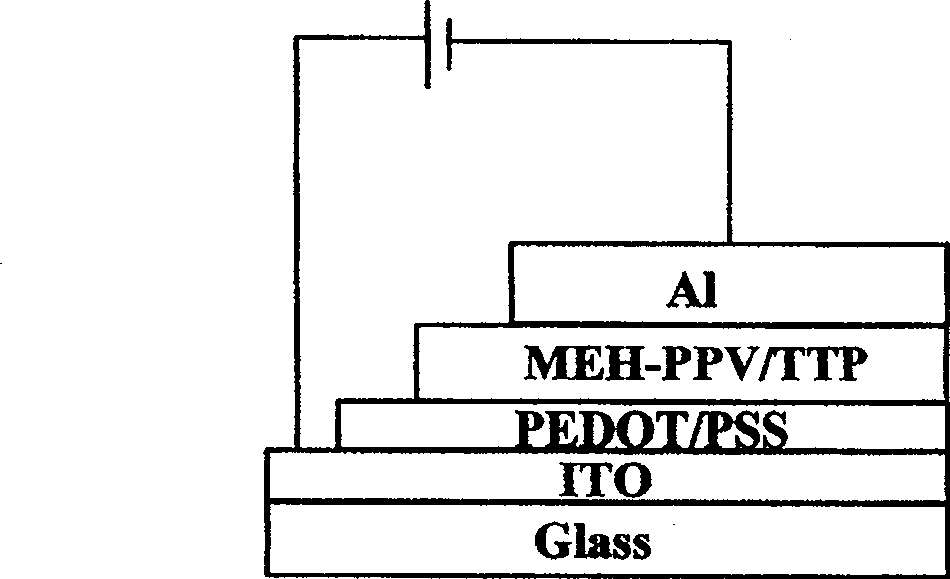

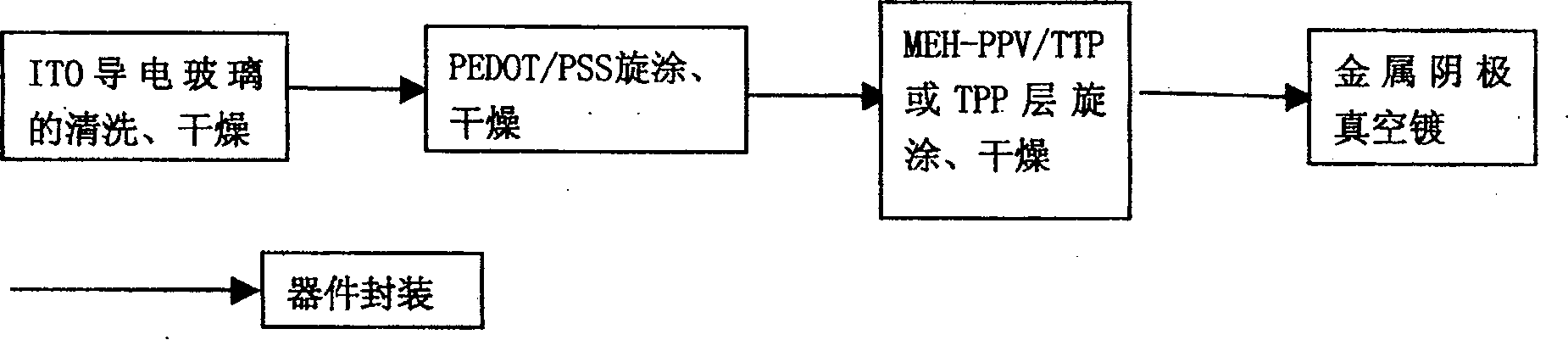

[0069] Device preparation method:

[0070] (1) Doping method: The doping ratio is the weight percentage of TTP or TPP added according to the weight of MEH-PPV, and they are put into a certain amount of organic solvent at the same time to form a mixed solution. The concentration is 1-8%, preferably 3%.

example 1

[0071] Example 1: Add 0.6mg of TTP to 20mg of MEH-PPV, then dissolve them in 1ml of chloroform to form a mixed solution, filter it with a 0.45μm filter, and then use it for spin coating to form a membrane.

example 2

[0072] Example 2: Add 0.6mg of TPP to 20mg of MEH-PPV, then dissolve them in 1ml of chloroform to make a mixed solution, filter it with a 0.45μm filter, and then use it for spin coating to form a membrane.

[0073] (2) The manufacturing process of the device: refer to figure 2 , on the cleaned ITO, apply a 20nm thick PEDOT / PSS film layer by spin coating method, and dry it in vacuum to remove the remaining solvent; then apply a 100nm thick MEH- PPV+3%TTP light-emitting layer, vacuum-dried to remove residual solvent; finally, use vacuum coating technology to deposit a metal cathode with a thickness of 100nm, and the metal cathode can be specifically Al. The thickness of the film layer affects the light emission of the device. Too thick or too thin will affect the light emission, and some may even not emit light.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com