Method and device for dehulling separation of flax seed

A separation method, linseed technology, applied in the direction of solid separation, electrostatic effect separation, chemical instruments and methods, etc., can solve the problems of complex structure of separation equipment, low separation efficiency, high failure rate, etc., to shorten the process time and simplify the equipment system , Energy consumption and failure rate reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

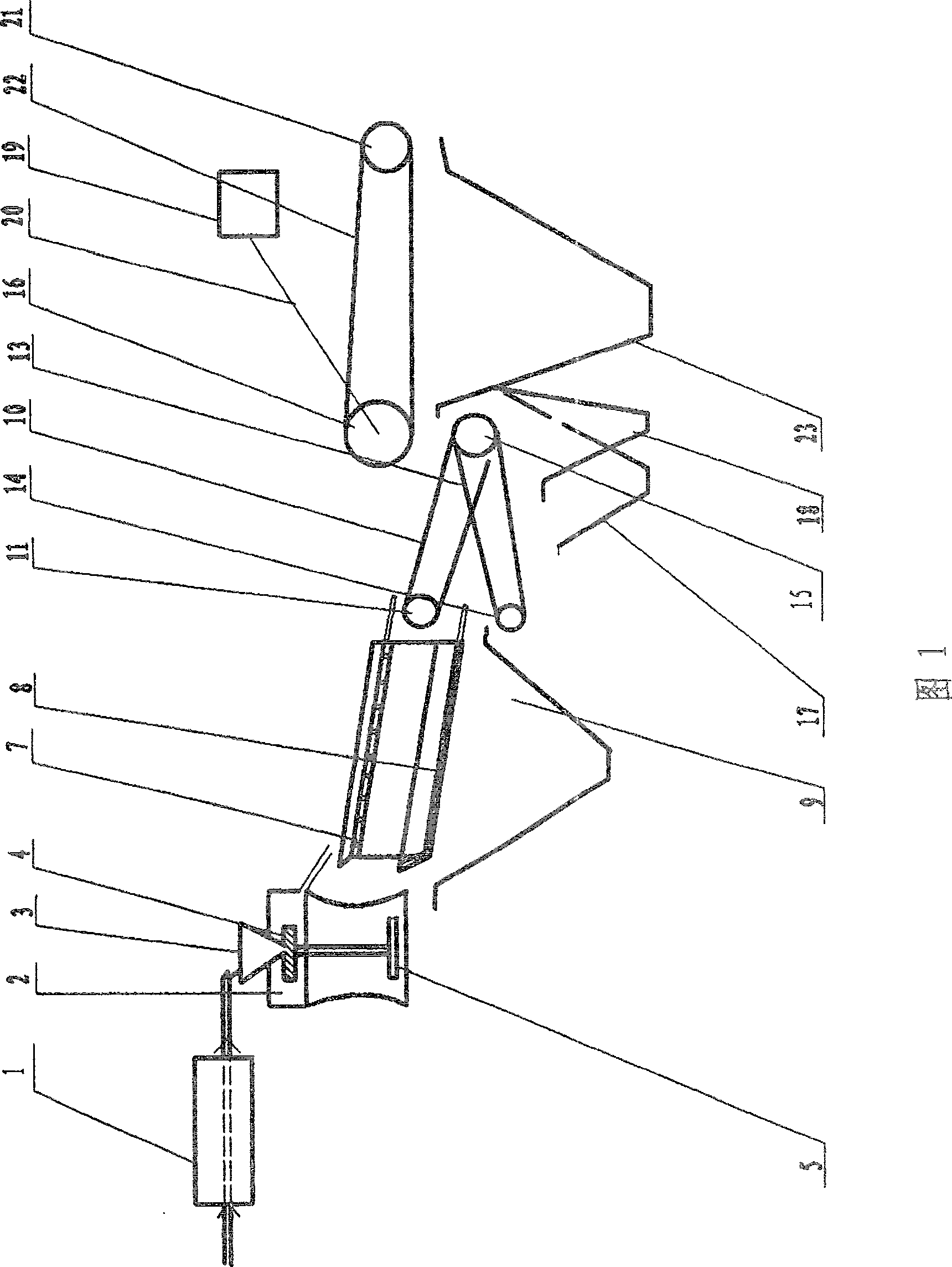

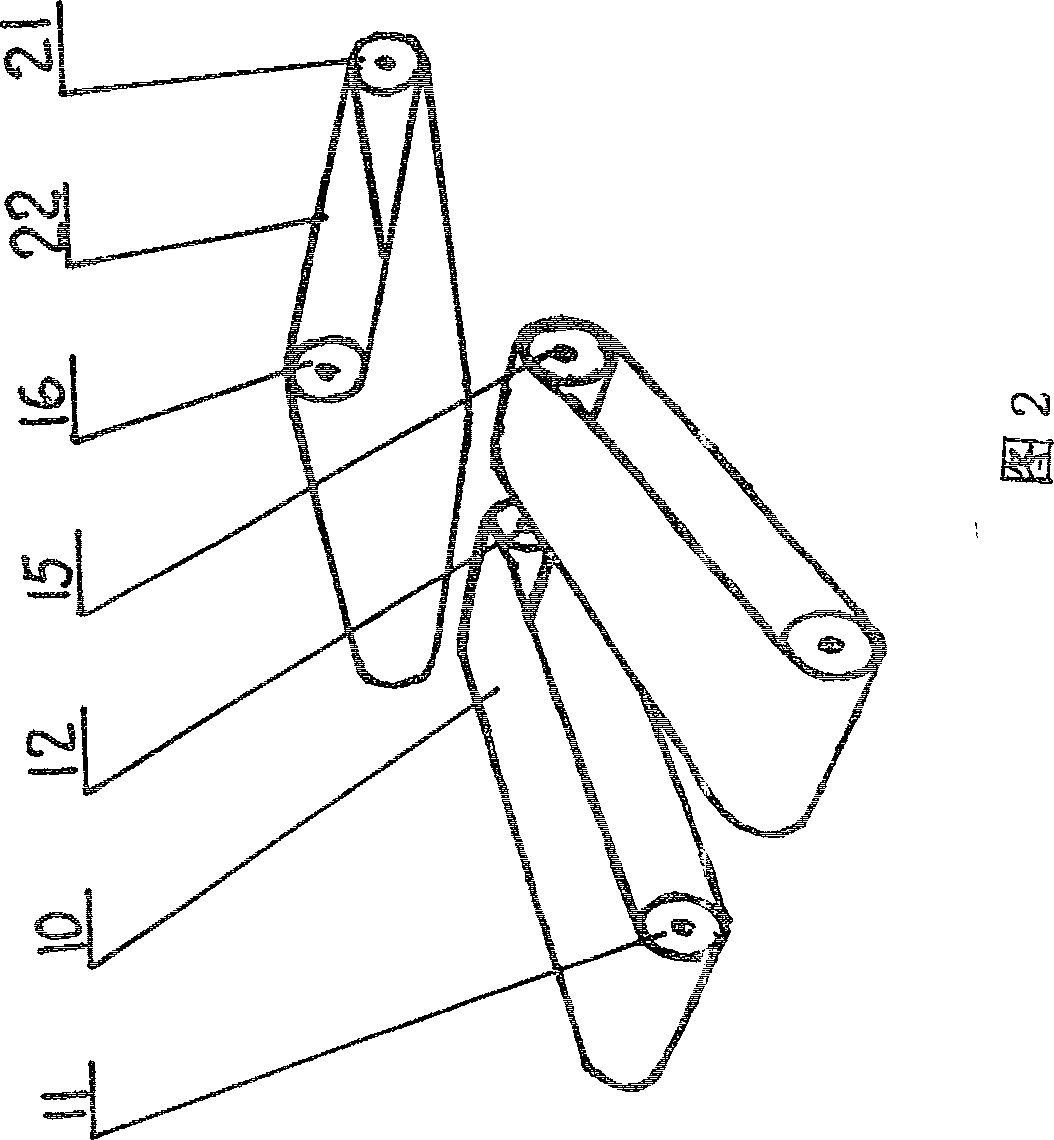

[0027] Embodiment 1 200 kilograms of flax seeds are dried to a moisture content of 4%, and are sent into a centrifugal peeling machine at a speed of 2 kilograms per minute. The radius of the accelerating drum 4 is 15 cm, and the height is 50 cm. A circular hole with a diameter of 12mm, and the rotating speed of the drum is 2500 rpm. The shell radius of centrifugal peeling machine is 50cm. The peeling rate reaches 60%. The upper screen of the screen equipment is 12 mesh, and the lower screen is 36 mesh. Electrostatic roller voltage 8000 volts. The separation rate of shell skin and kernel is 97%.

Embodiment 2

[0028] Embodiment 2 200 kilograms of flax seeds are dried to a moisture content of 2%, and are sent into a centrifugal peeling machine at a speed of 2 kilograms per minute. The radius of the accelerating drum 4 is 15 cm, and the height is 50 cm. A circular hole with a diameter of 12mm, and the rotating speed of the drum is 3500 rpm. The shell radius of the centrifugal peeling machine is 50cm, and the peeling rate reaches 65%. The upper screen of the screen equipment is 10 mesh, and the lower screen is 40 mesh. Electrostatic roller voltage 6000 volts. The separation rate of shell skin and kernel is 98.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com