Method and device for measuring transverse pressure for powder flow warm compaction

A transverse pressure and warm pressure forming technology, applied in the field of material processing, can solve the problems of manufacturing technology and its process principle research that have not yet been reported, and achieve the effect of intuitive measurement method, high accuracy and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

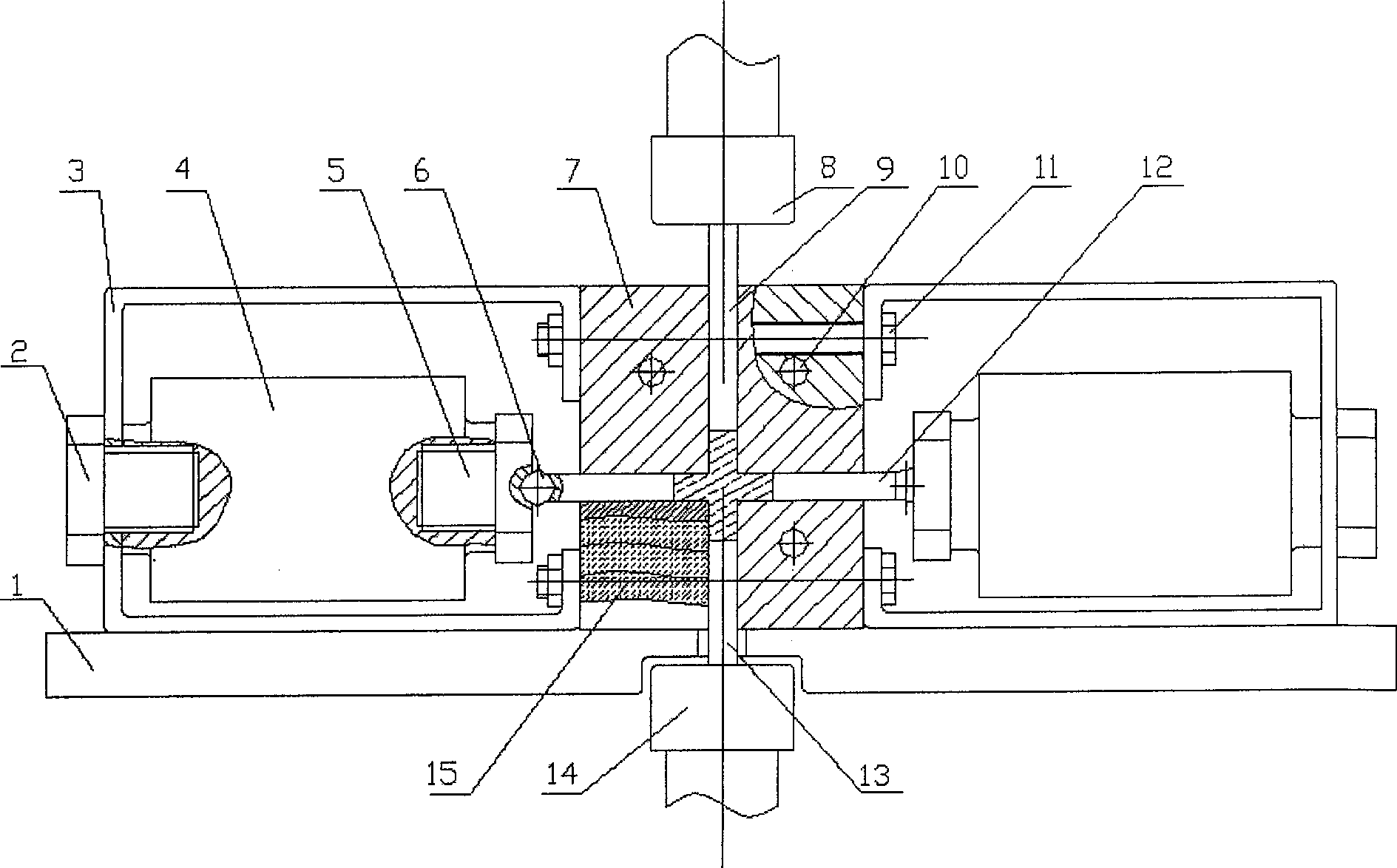

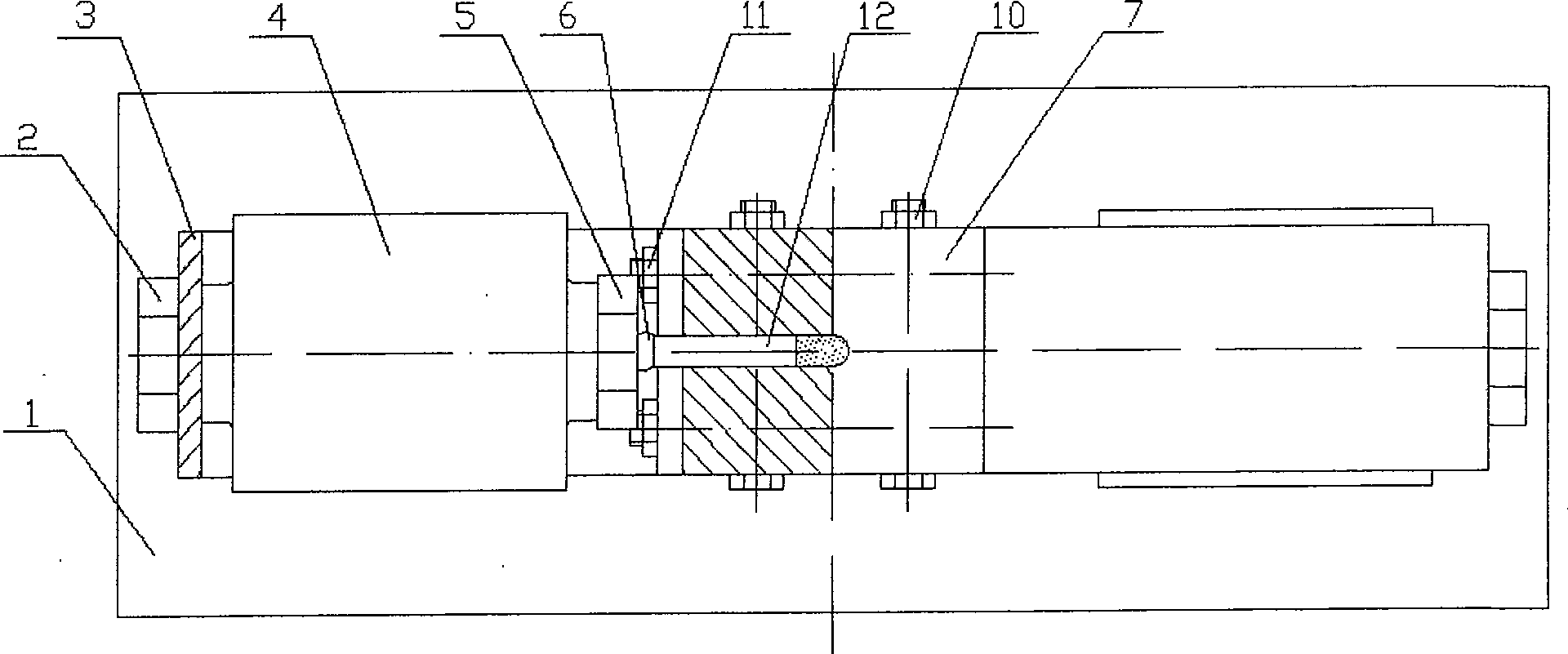

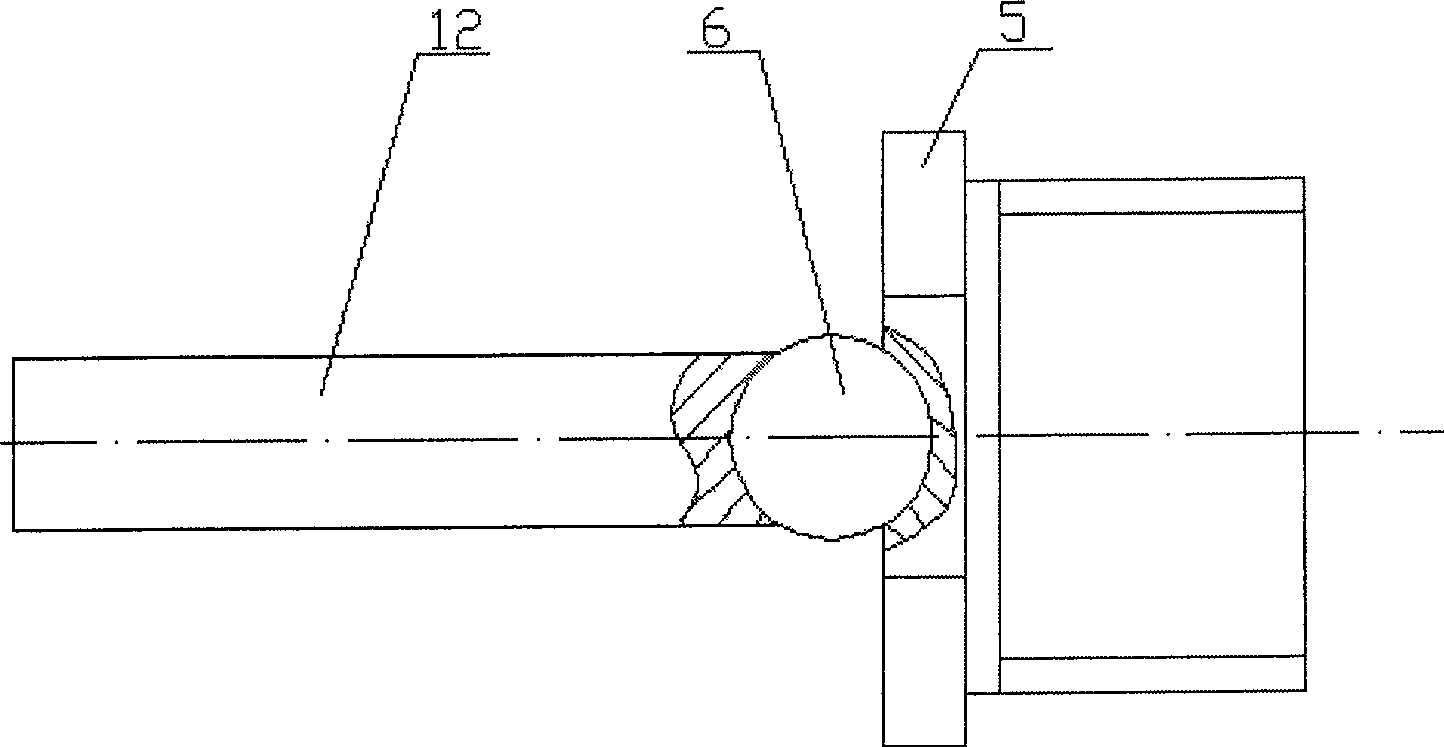

[0022] Such as figure 1 , figure 2 As shown, the powder flow warm pressing forming lateral pressure measuring device is composed of two ejector rods 12, two steel balls 6, two upper and lower die punches 9, 13, two screw ejector columns 5, and two sensor fixing frames installed symmetrically. 3. It is composed of two fixing bolts 2, two pressure sensors 4, a cross mold 7 that can be split into molds for opening and closing, a heating device 15, and a data acquisition card. Such as image 3 Shown is a schematic diagram of the structure of the ejector rod and the screw ejector column connected by steel balls of the measuring device for the lateral pressure of powder flow warm compaction. Clamp the two cross-shaped molds 7 with four sets of bolts 10, and fix the two sensor holders 3 on both sides of the mold cross-shaped mold 7 with four sets of bolts 11; Insert the transverse mold cavity matched with the ejector rod 12 on both sides, screw the two screw ejector columns 5 int...

Embodiment 2

[0027] Such as Figure 4 As shown, in this device, the push rod 12 is directly connected with the screw top column 5, that is, it is not connected by a steel ball. The end face of the push rod 12 is flat and cooperates with the screw top column 5 whose end surface is also flat; the screw top column 5 is connected with the pressure sensor 4 . This embodiment requires that the verticality between the end face of the ejector rod 12 and the centerline of the spiral ejector column 5 and the perpendicularity between the end surface of the spiral ejector column 5 and the center line of the spiral ejector column 5 reach more than 7 levels of perpendicularity, which can avoid causing the ejector rod Tilt to meet the test conditions. In this way, the change of the lateral pressure can also be displayed continuously and directly on the indicator connected to the pressure sensor 4 . All the other implementations are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com