Electric-controlled diesel oil fuel oil injector driven by telescoping element

A technology of diesel fuel injector and fuel injector, which is applied in the direction of engine components, machines/engines, fuel injection devices, etc., to achieve the effect of high-pressure diesel injection, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

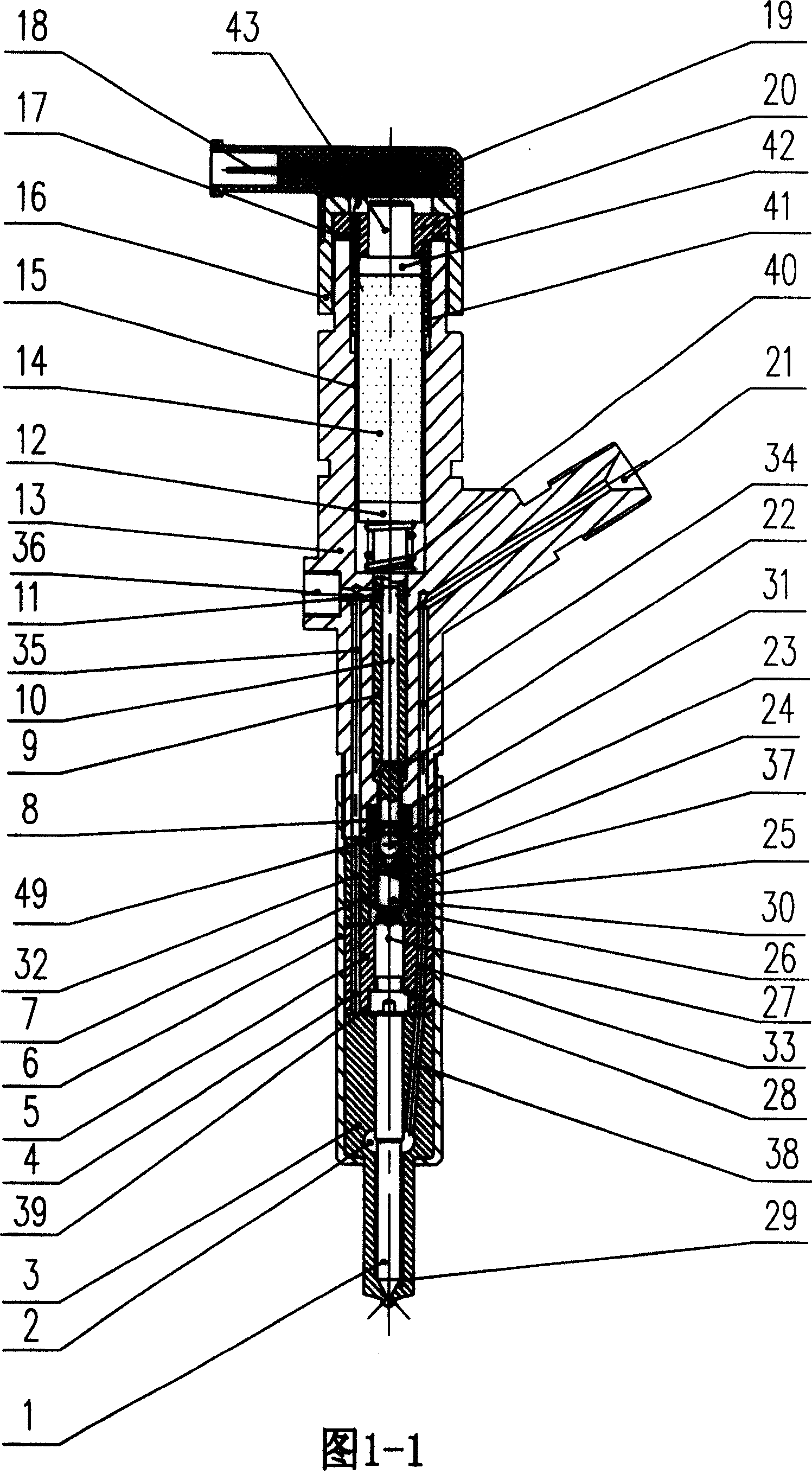

Embodiment 1

[0030] An electronically controlled diesel fuel injector driven by an electrostrictive element, in which a push rod spring (40), a push rod (9), and a push rod seat (12 ), consisting of an electrostrictive element (14), a plastic spacer (15) covering the outer lower part of the electrostrictive element (14) and an insulating cylinder (41) covering the outer upper part of the electrostrictive element (14) The electrostrictive element assembly, the gasket (42), the upper end cover (20), the axial positioning shaft (43), and then tighten the upper nut (16), and install the ball valve seat at the lower end of the injector housing (13) (8), install the injector assembly (1) and (3), the command plunger (27) and the command plunger valve body (5), the command oil chamber valve body (7) in sequence in the nut sleeve (6) ), spring (24), steel ball seat (37) and steel ball (23), wherein the steel ball (23) and the steel ball seat (37) are welded together, the lower end surface of the i...

Embodiment 2

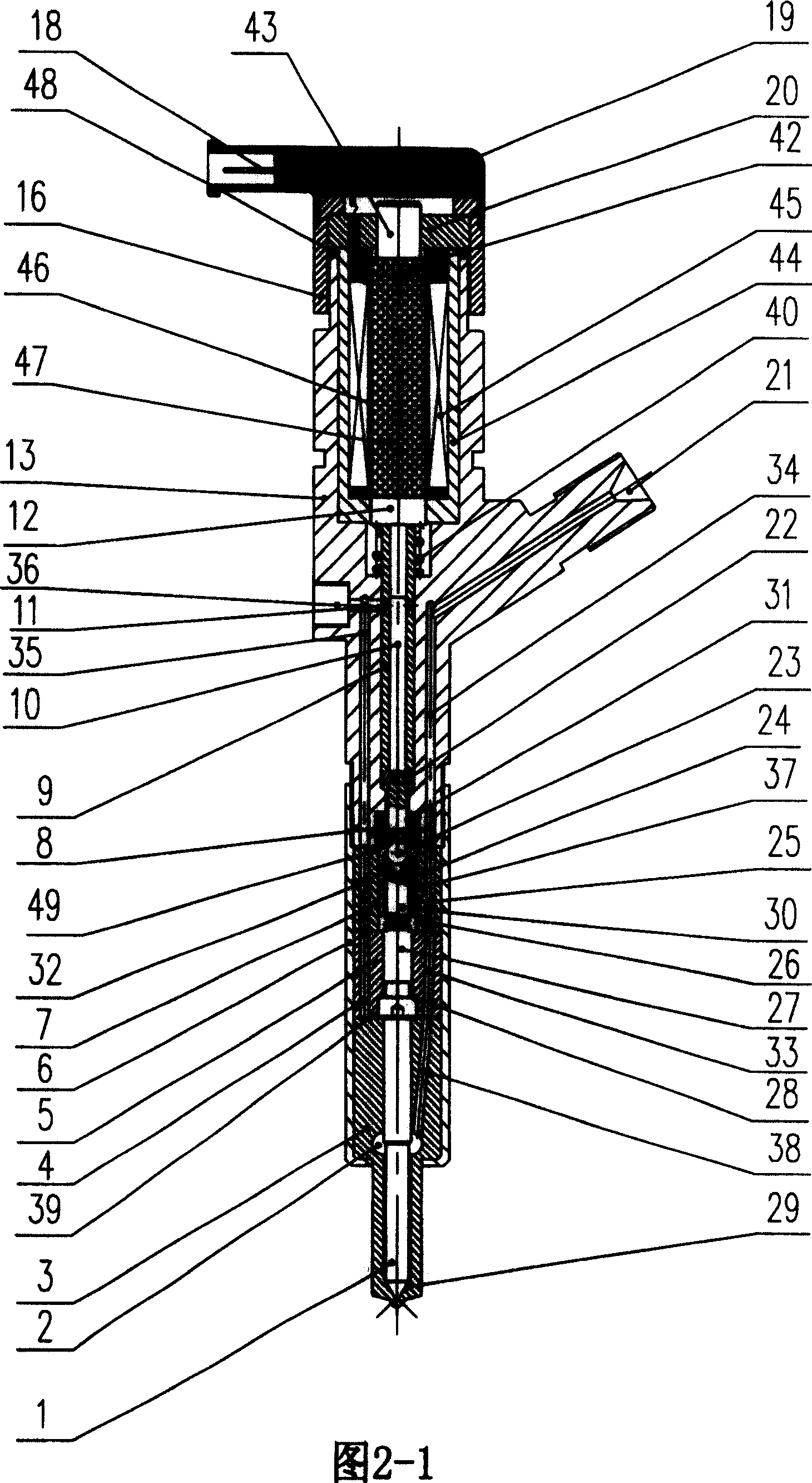

[0042] An electronically controlled diesel fuel injector driven by a magnetostrictive element, its basic structure is the same as that of Embodiment 1, the difference lies in: a push rod seat (12), a gasket ( There is no electrostrictive element assembly between 42), but a wire frame (46) made of a magnetic sleeve (44) and a magnetic wire (45) is installed, placed inside the wire frame (46), and positioned at the push rod seat. (12), the magnetostrictive element assembly composed of the magnetostrictive element (47) between the spacers (42), the push rod spring (40), Push rod (9), push rod seat (12), and the wire frame (46) that is wound with electromagnetic wire (45) by magnetic conduction cover (44), is positioned at the magnetostrictive element (47) on the wire frame (46) ) composed of a magnetostrictive element assembly (see Figure 2).

[0043] The fuel injector housing (13) is also a cylinder with unequal diameters like the housing (13) in Embodiment 1, with a large uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com