Automatic reforming device for fireworks cylinder

A technology of shaping devices and fireworks tubes, which is applied in pyrotechnics, offensive equipment, weapon types, etc., can solve problems such as increasing labor intensity of workers, deformation of paper tubes, and stoppage of jamming tubes, so as to reduce labor intensity of workers and prevent jamming The effect of stopping the machine without stopping and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

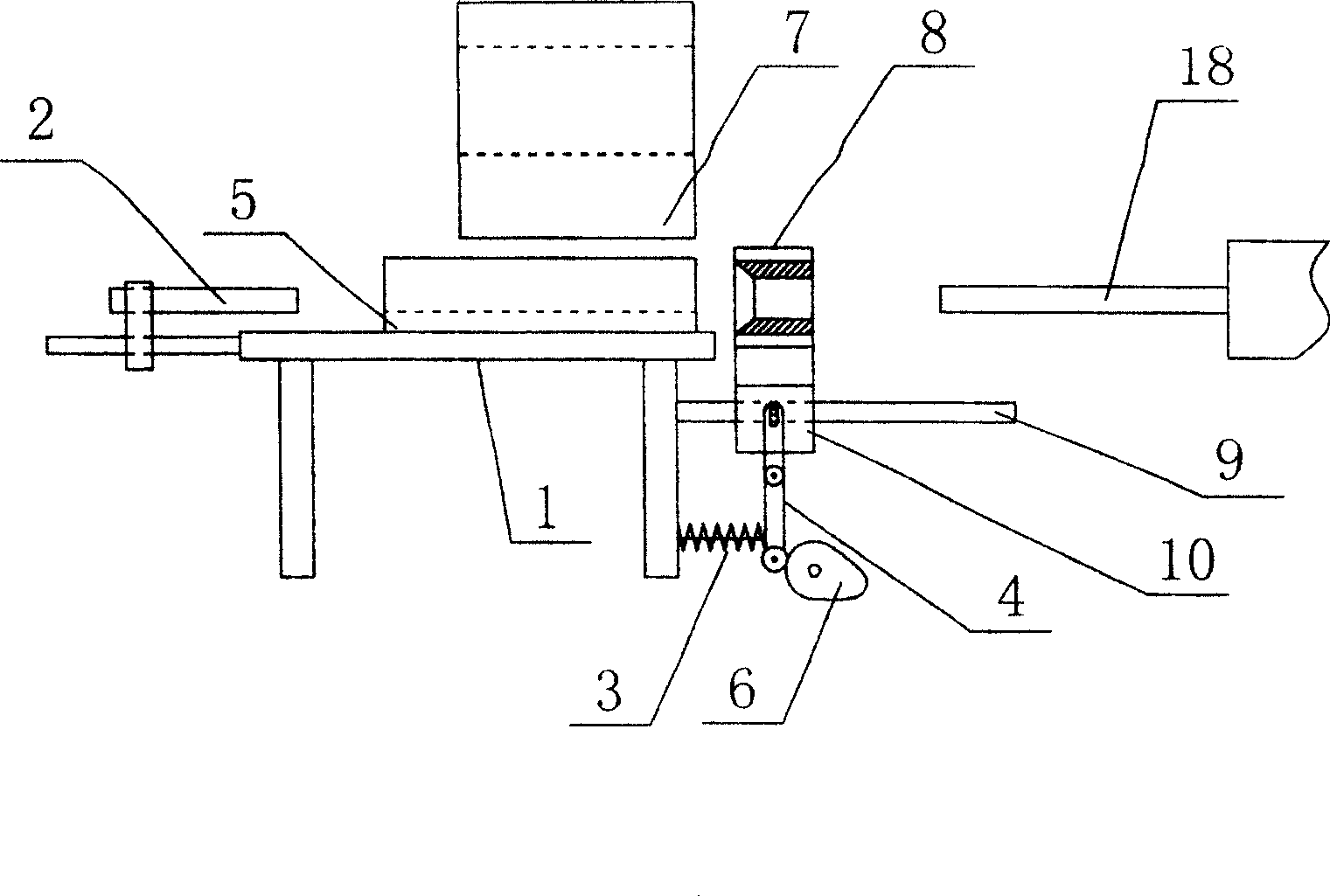

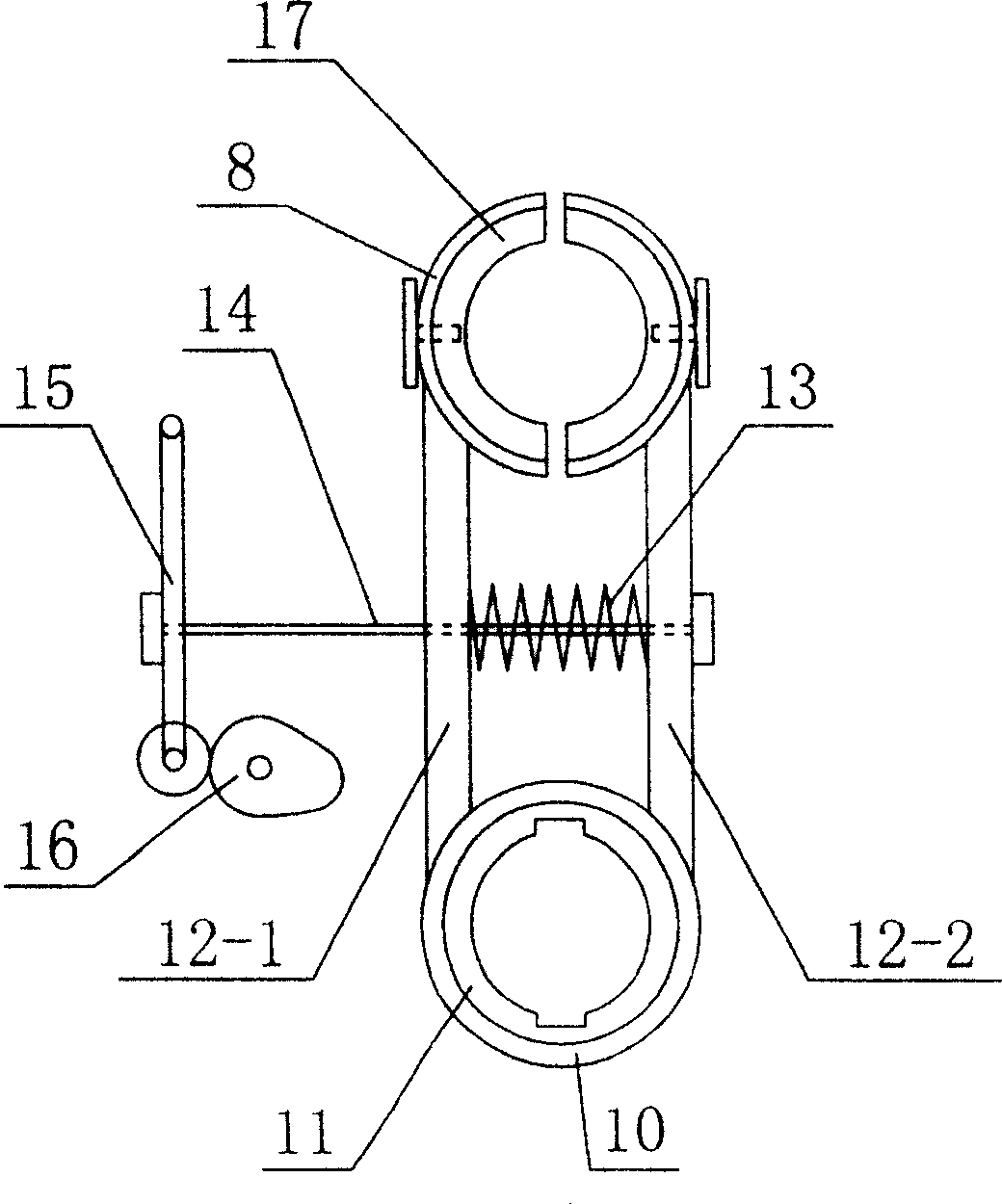

[0023] Refer to attached figure 1 , 2 , the present embodiment includes a frame 1, a cylinder body shaping mechanism, and the cylinder body shaping mechanism is arranged at the discharge port of the trough-shaped material channel 5 of the upper cylinder device of the fireworks and firecracker machine, and it includes a shaping jacket 8, a slide rod 9, and is sleeved on the The sliding sleeve 11 on the sliding rod 9, the cam drive mechanism I6, the outer side of the sliding sleeve 11 is covered with an annular sleeve 10, the shaping jacket 8 is composed of two semi-circular sleeves, and the semi-circular sleeve on one side is installed by a fixed arm 12-1 On the sliding sleeve 11, the other side of the semi-circular sleeve is installed on the annular sleeve 10 through another fixed arm 12-2, and a replaceable bushing 17 is arranged inside the shaping jacket, and the sliding sleeve 11 is hinged on the frame 1 The shift lever 4 on the top is connected with the cam driving mechan...

Embodiment 2

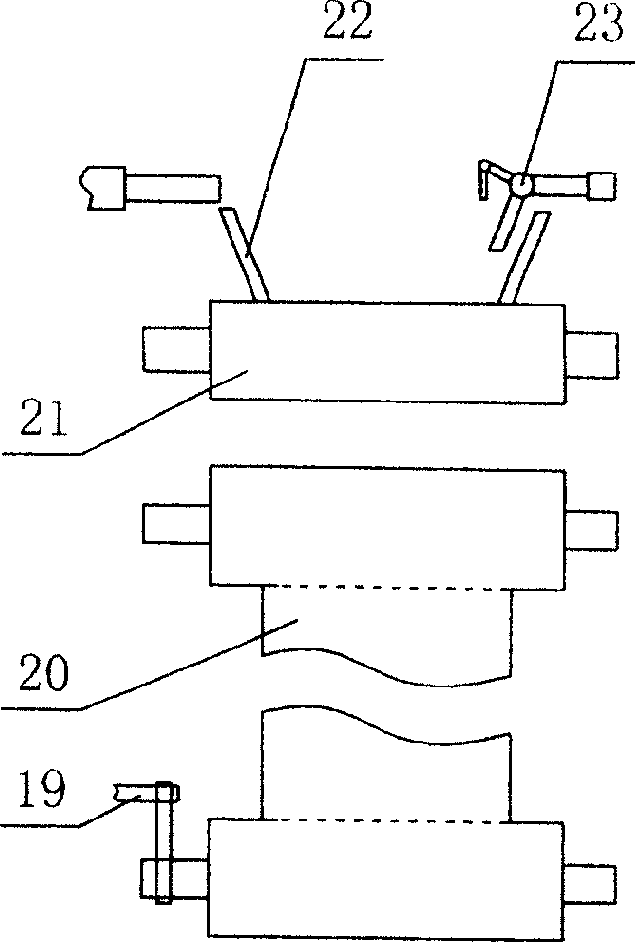

[0026] refer to Figure 4 The difference between the structure of this embodiment and Embodiment 1 is that the opening and closing mechanism of the shaping collet 8 consisting of a compression spring 13' and a backguy 14' is located at the lower part of the sliding sleeve 11, and the fixing arm 12-1' of the shaping collet 8, 12-2' is in the shape of a scissors fork, and the intersection is movably sleeved on the sliding sleeve 11, and the driving mechanism is a hydraulic cylinder 24. All the other are with embodiment 1.

Embodiment 3

[0028] refer to Figure 4 , the structure of this embodiment differs from that of Embodiment 2 in that the compression spring 13' Figure 4 The position shown is moved to the upper part of the sliding sleeve 11. All the other are with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com