Leakage checking up device for fuel oil vapour eliminating system

A technology of cleaning system and inspection device, which is applied in the application of electrical devices to test fluid tightness, measuring devices, charging systems, etc., can solve the problems of inability to meet the leakage reference value and leakage reference value, and it is difficult to improve the leakage inspection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

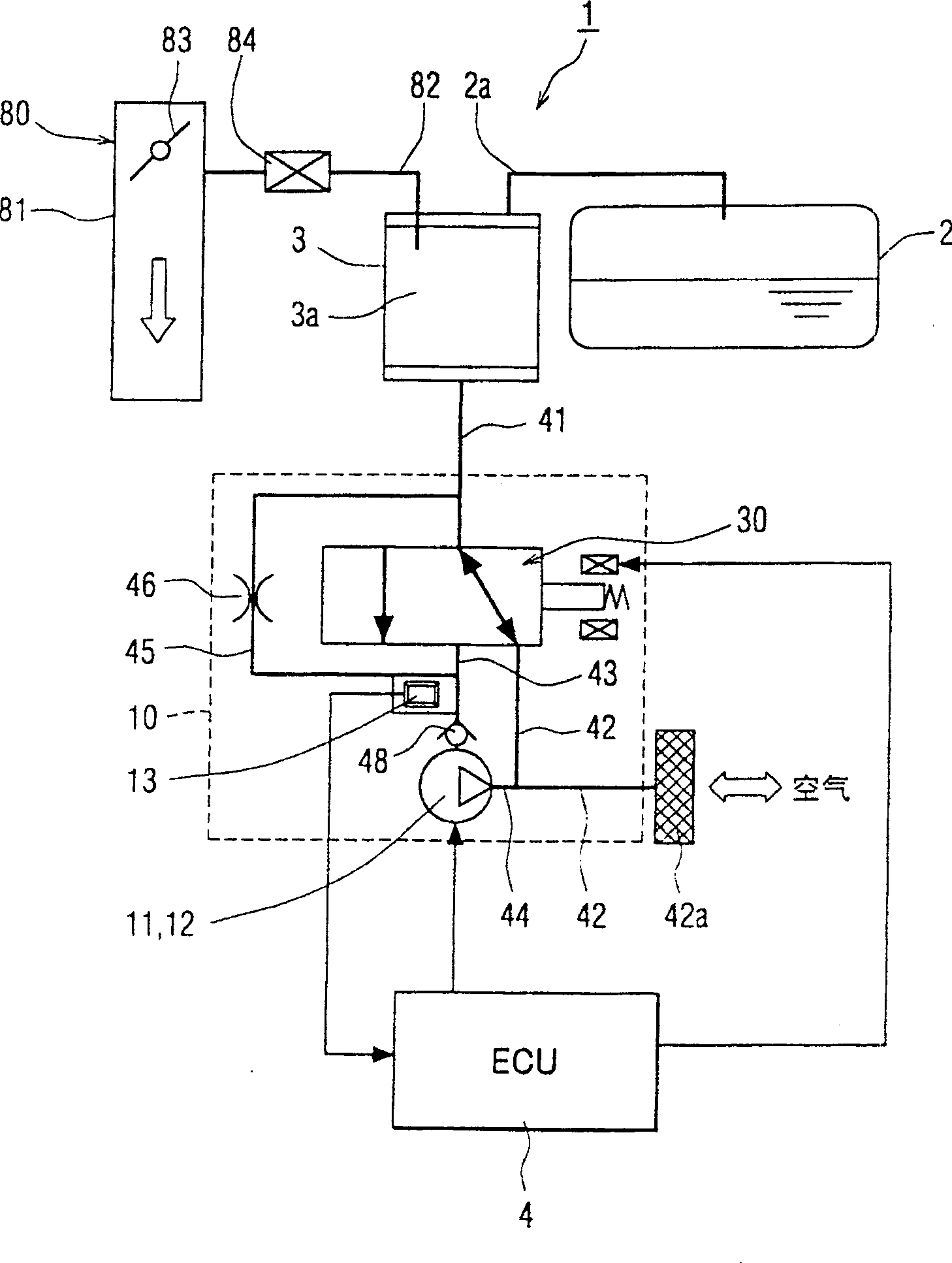

[0033] like figure 1 As shown, the fuel vapor removal system includes: a fuel tank 2; a carbon canister 3 as an adsorption filter, which is connected with the fuel tank 2 through a connection flow channel 2a, and also has a ventilation flow channel 41; Valve desorption control valve 84. One end of the vent valve 84 is connected to the carbon canister 3 through a valve flow channel 82 , and the other end is connected to the intake system 80 of the internal combustion engine through the valve flow channel 82 . The canister 3 contains an adsorbent such as activated carbon.

[0034] Part of the fuel contained in the fuel tank 2 evaporates, thereby generating fuel vapor in the fuel tank 2 . The fuel vapor is guided into the canister 3, and is temporarily adsorbed and accumulated in the canister. When the desorption control valve 84 is opened by the low-pressure air in the intake system 80 , the air is sucked in through an external flow channel 42 , the carbon canister 3 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com