Self-adapting wire coil to power of induction cooker

A self-adaptive, induction cooker technology, applied in applications, household stoves/stoves, electric heating fuels, etc., can solve problems such as bursting, wire coil insulation breakdown, adverse resonance, etc., to alleviate the influence of thermostat and automatic functions, and improve power factor, optimizing the effect of electromagnetic coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

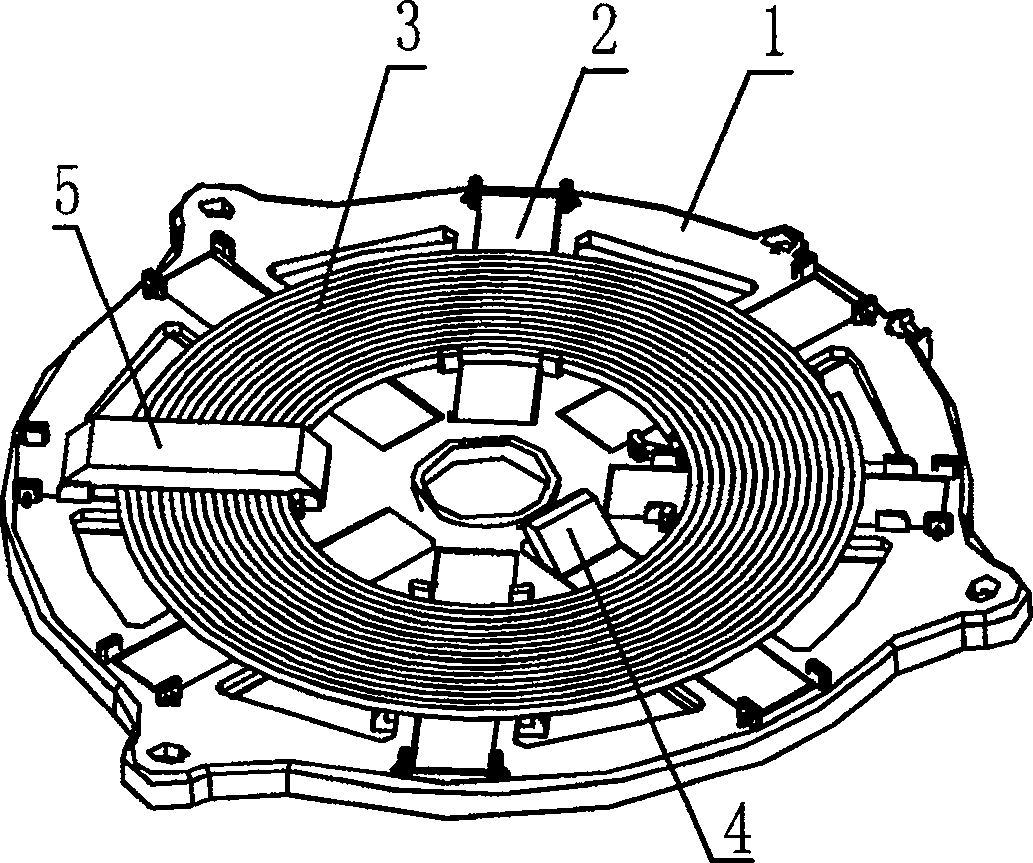

[0020] like figure 1 As shown, a power self-adaptive wire reel for an induction cooker includes a bracket 1, a radially distributed magnetic strip 2, and a coil 3 fixed on the bracket. The proximal end of the magnetic strip has an upward corner 4, and the height of the corner 4 is greater than the height of the upper surface of the annular magnetizer, with a height difference of 3mm.

[0021] Of course, the annular magnetizer is formed by enclosing one of the magnetic strips and the magnetizer.

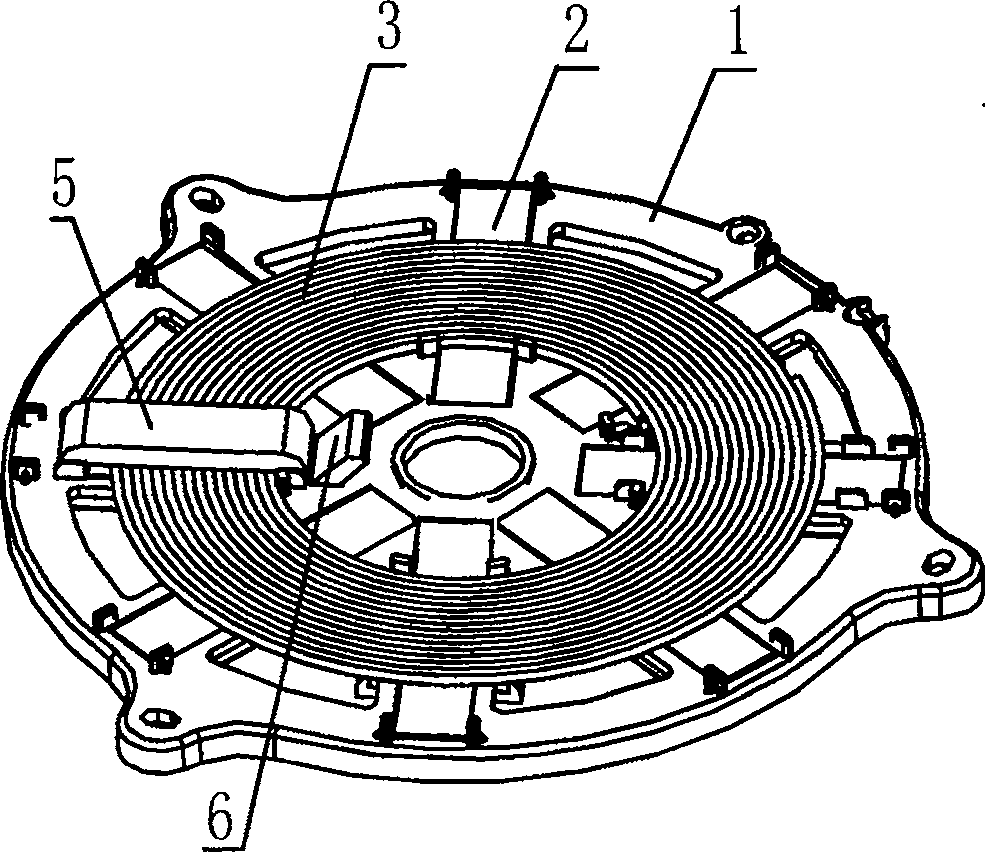

[0022] like figure 2 As shown, an induction cooker power self-adaptive reel includes a bracket 1, a radially distributed magnetic strip 2, a fixed coil 3 on the bracket, and the coils 3 all pass through a ring-shaped magnetizer 5, and the ring-shaped magnetizer 5 The proximal end has an upward corner 6, and the height of the corner 6 is greater than the height of the upper surface of the annular magnetizer, with a difference of 0.1mm in height.

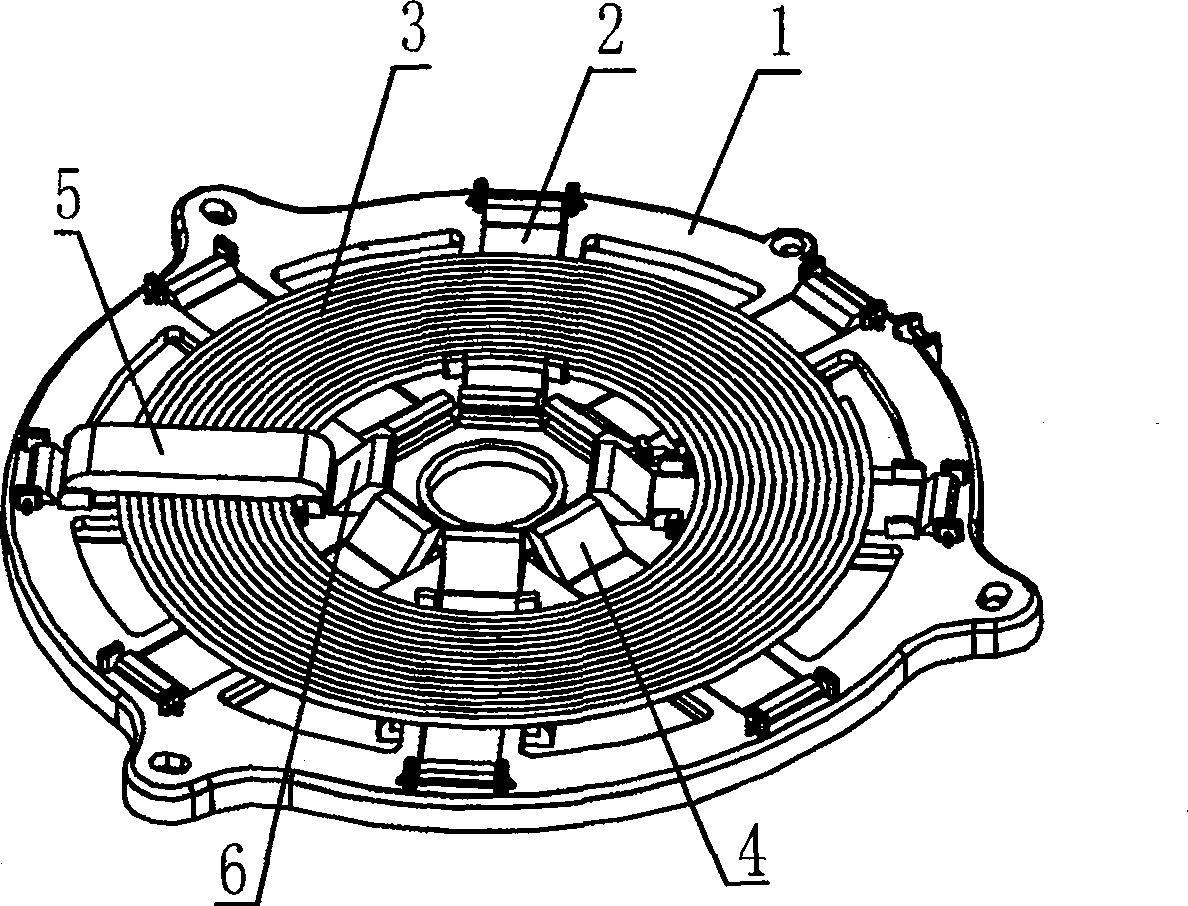

[0023] like image 3 As shown, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com