Method for realizing bar array semiconductor laser shaping by means of reflecting prism stack

A technology of lasers and semiconductors, applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problems of inconvenient adjustment and mechanical parts design, unfavorable cost, and inconvenient adjustment, so as to achieve the promotion of the method and the cost. The effect of reducing and adjusting is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

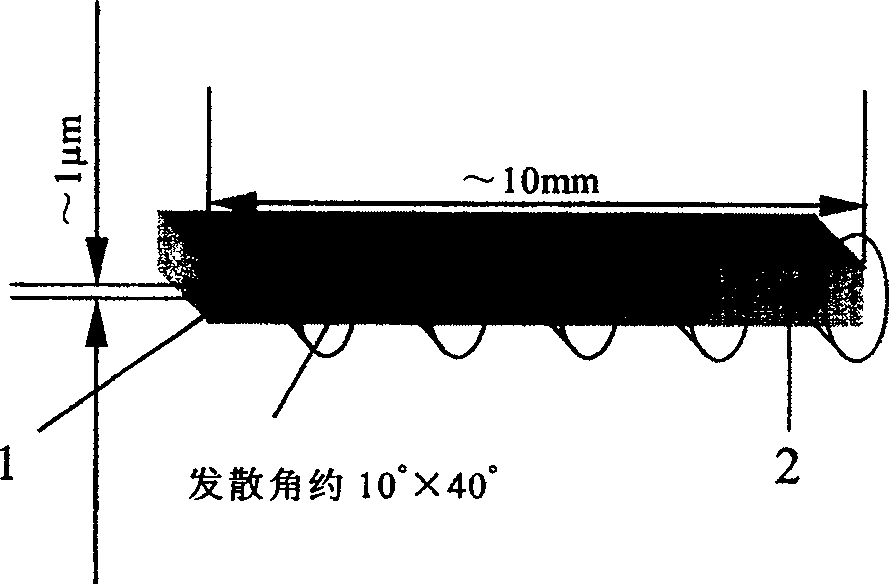

[0025] The strip semiconductor laser designed by the method of the present invention realizes the shaping process coupled with 800 μm core diameter, 0.37 numerical aperture optical fiber, and its design process is as follows:

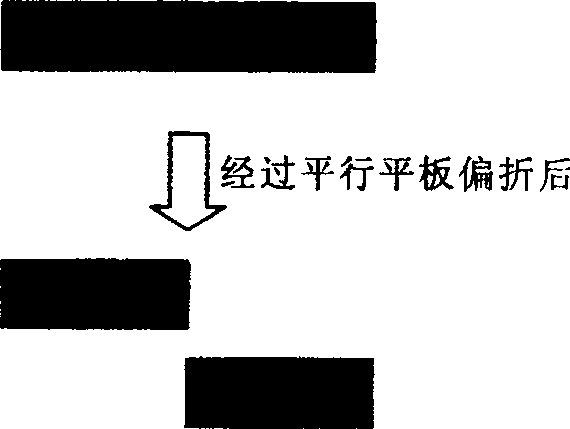

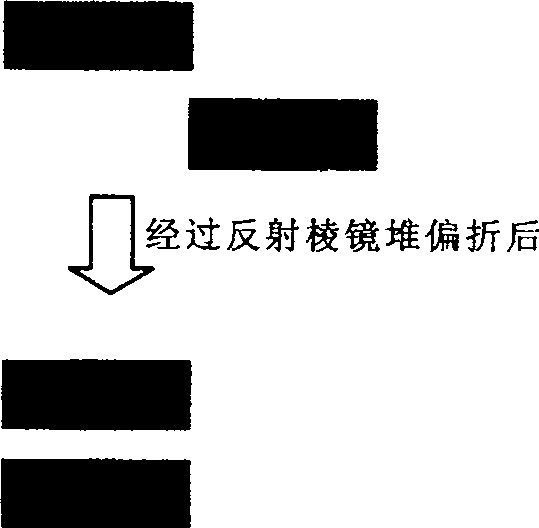

[0026] (1) In this embodiment, after the fast and slow axes of the strip semiconductor laser are collimated, the spot size in the slow axis direction is about 10mm, and the slow axis spot is deflected twice by a catadioptric prism stack, and aligned along the fast axis direction. The shaping system needs a reflective prism stack composed of a parallel plate and two reflective prisms. For the laser wavelength of 808nm, you can choose cheap K9 glass to make a parallel plate. Because the slow axis beam has a certain divergence, the length of the parallel plate is selected as 7mm. If the laser is 7.5mm away from the base, the height of the parallel plate can be chosen to be 12mm. In this example, the width of the parallel plate is selected as 5mm. In orde...

Embodiment 2

[0033] (1) In this embodiment, after the fast and slow axes of the strip semiconductor laser are collimated, the spot size in the slow axis direction is about 10mm, and the slow axis spot is deflected three times by using a catadioptric prism stack, and aligned along the fast axis direction. The shaping system requires a reflective prism stack composed of two parallel flat plates and three reflective prisms. As in the first embodiment, the parallel plate is made of K9 glass, and the length of the parallel plate is selected as 4 mm because the slow-axis light beam has a certain divergence. If the laser is 7.5mm away from the base, the height of the parallel plate can be chosen to be 12mm. In this example, the width of the parallel plate is selected as 5mm. In order to ensure that the light spots in the fast axis direction are as compact as possible without overlapping, the distance between the centers of the two light spots in this direction is selected as 1mm. The height of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com