Method of eliminating arsenic by fluosilicic acid

A technology of fluosilicic acid and arsenic content, applied in the direction of silicon halide compounds, etc., can solve problems such as loss of fluosilicic acid, increase of impurities in fluosilicic acid solution, etc., achieve the effect of less investment, good arsenic removal effect, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

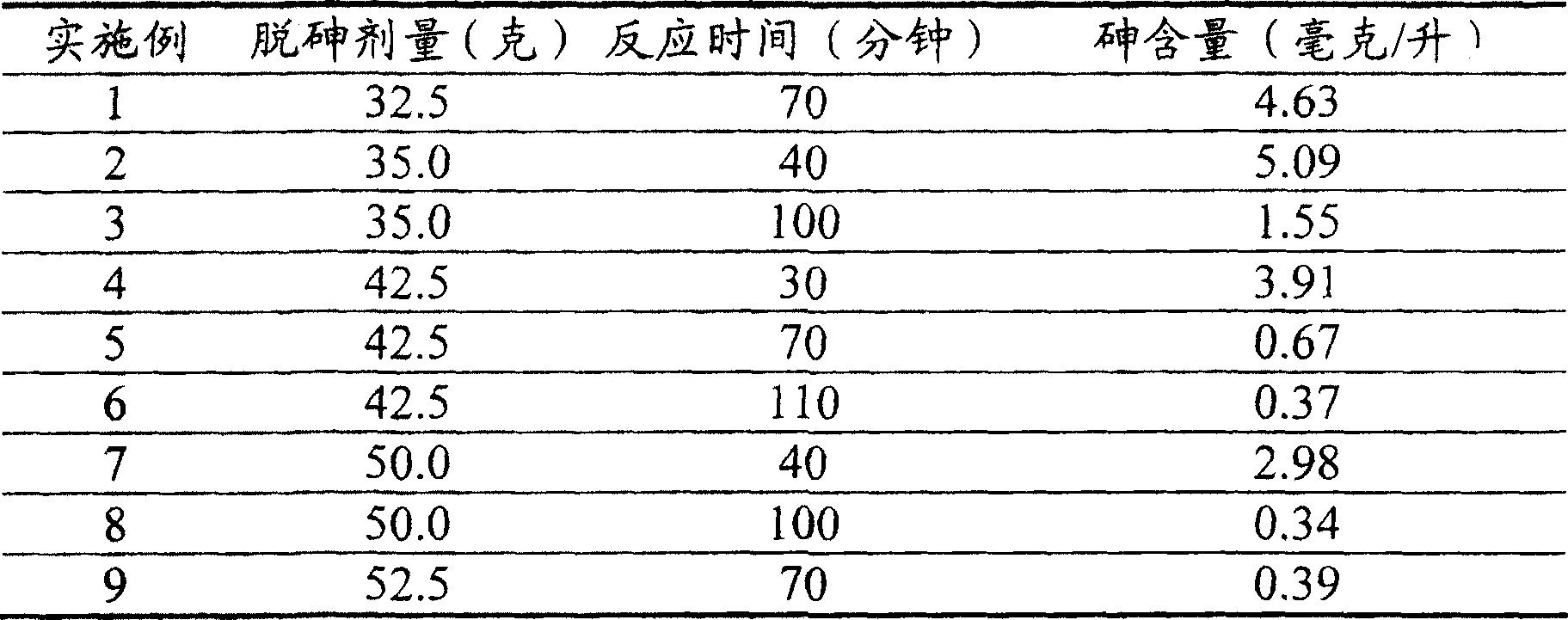

[0017] Take 10 liters (density is 1.17 kg / liter) of fluosilicic acid solution with arsenic content of 67.2 mg / liter and a weight concentration of 18.2% recovered in the wet phosphoric acid concentration process in the reactor, and control the temperature at 60°C. The stirring speed is 200 rpm. After reaching the specified temperature, add 32.5-52.5 grams of ferrous sulfide under stirring, react for 30-110 minutes, let stand for 22 hours and then filter.

[0018] Table 1 Reaction conditions and results of arsenic removal by fluorosilicic acid solution

[0019]

Embodiment 10

[0021] It is 10 liters (density is 1.20 kilograms / liter) of the fluosilicic acid solution 10 liters (density is 1.20 kilograms / liter) of 90.0 mg / liter, weight concentration 19.5% that the arsenic content that the wet-process phosphoric acid concentration process reclaims is in the reactor, and the control temperature is 50 ℃, and stirring speed is 50 rpm. After the specified temperature was reached, 50.0 g of ferrous sulfide was added under stirring, reacted for 100 minutes, left to stand for 1 hour, and then filtered to obtain arsenic content of 0.4 mg / L in a 19.7% arsenic-free fluorosilicate solution.

Embodiment 11-18

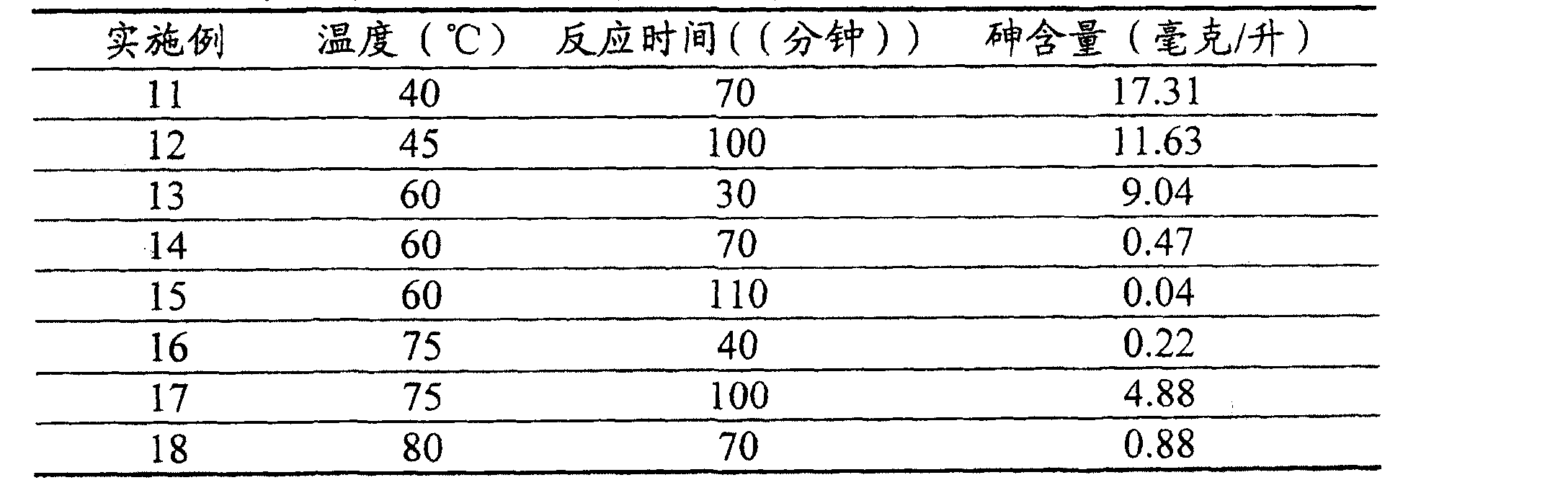

[0023] Take 10 liters (density is 1.19 kg / liter) of fluosilicic acid solution with arsenic content of about 54.5 mg / liter and a weight concentration of 19.1% recovered in the wet phosphoric acid concentration process in the reactor, and control the temperature at 40-80°C. The stirring speed was 400 rpm. After reaching the specified temperature, add 45 grams of ferrous sulfide under stirring, react for 30-110 minutes, let stand for 6 hours and then filter. The arsenic content of the obtained arsenic-free fluorosilicate solution is shown in Table 2.

[0024] Table 2 Reaction conditions and results of arsenic removal by fluorosilicic acid solution

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com