Biplate lock mould structure injection moulding machine and its manufacturing method

An injection molding machine and mold clamping technology, which is applied in the field of manufacturing method and equipment structure of the mold clamping part of the injection molding machine, and achieves the effects of compact structure, simple production and simplified mold clamping procedure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with the best embodiment shown in the accompanying drawings, it will be further described in detail.

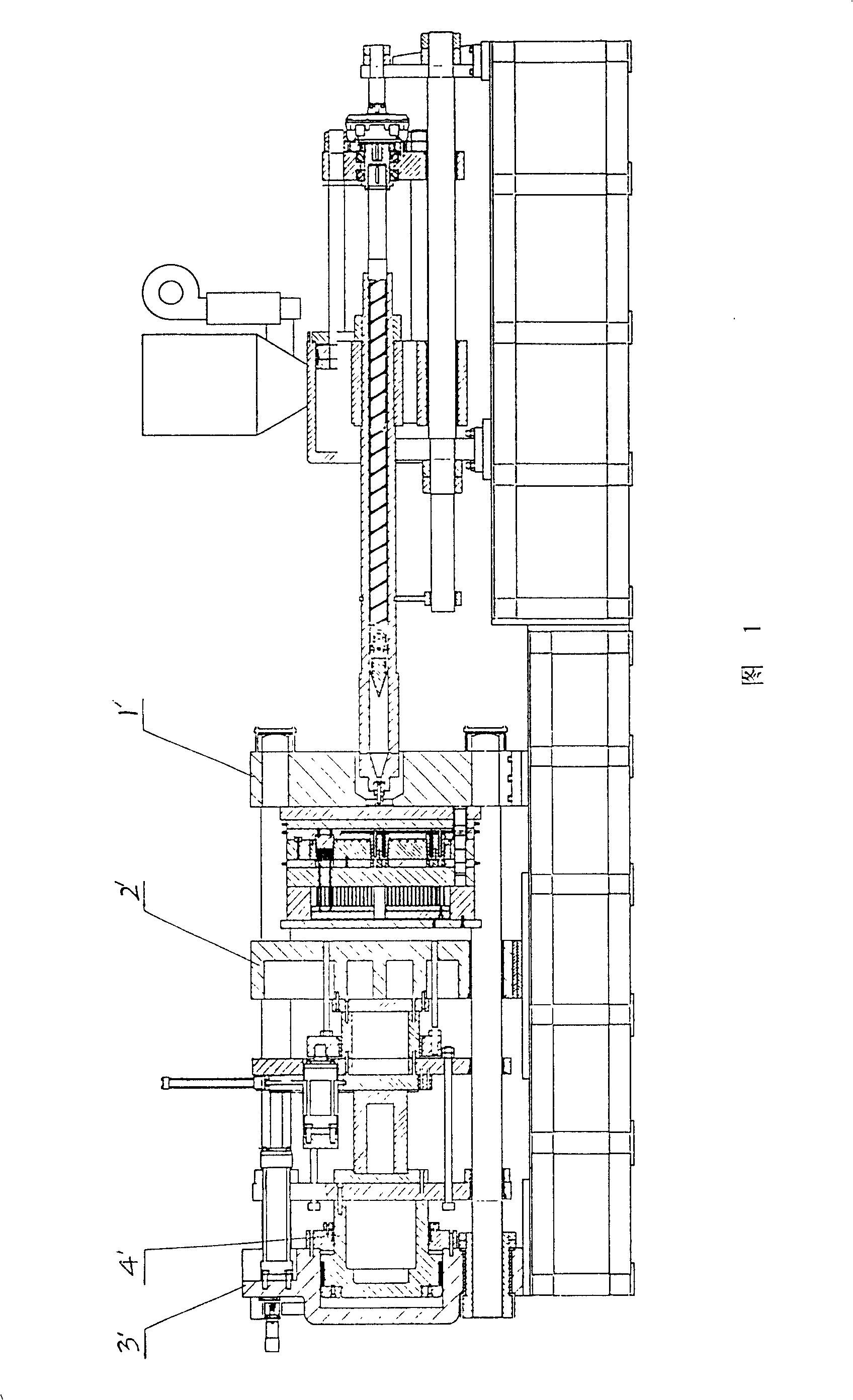

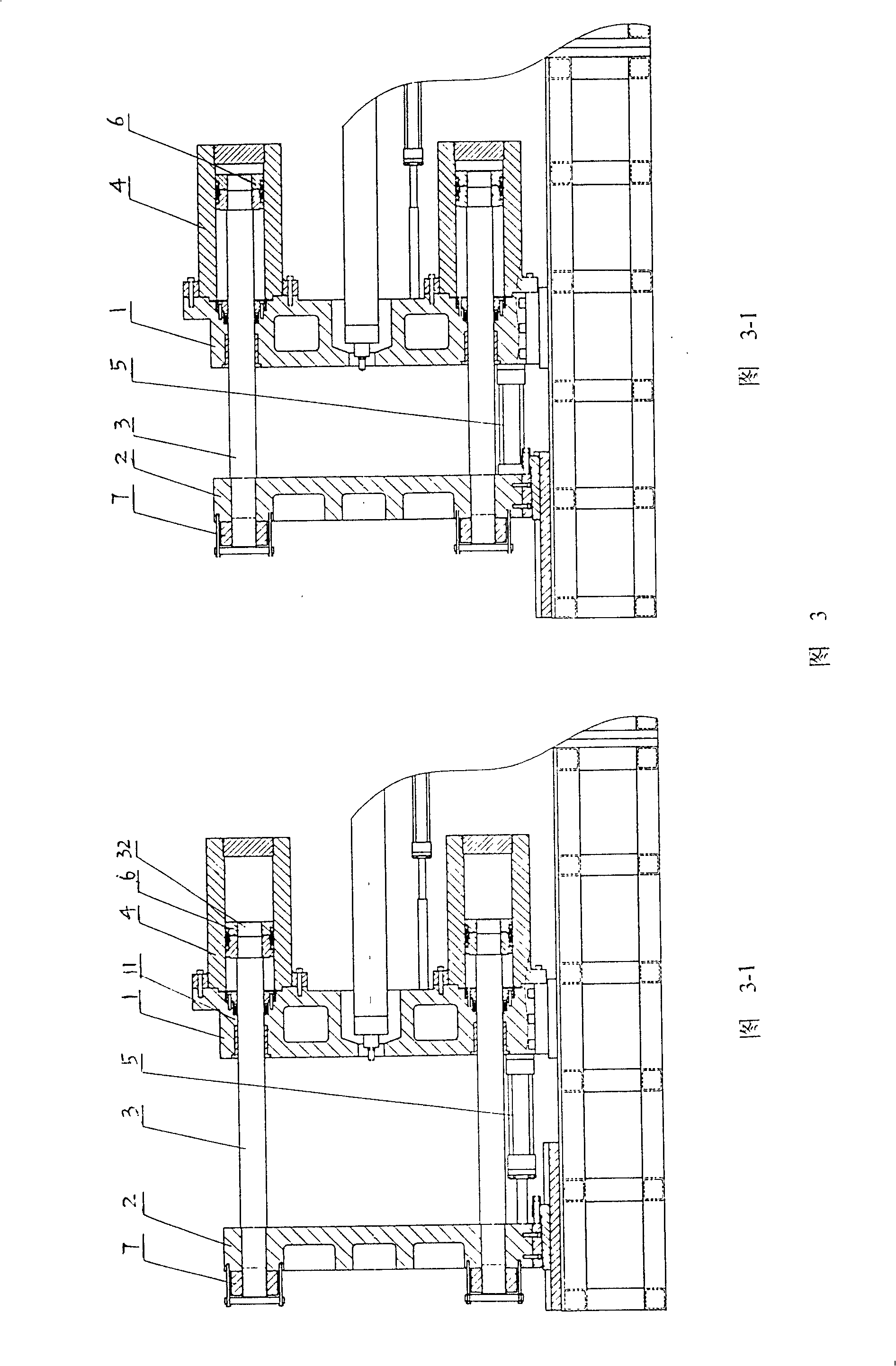

[0026] A method for manufacturing a double-plate clamping structure injection molding machine, as shown in Figure 3, comprising the following steps:

[0027] ①Arranging a fixed template 1, a movable template 2, four clamping rods 3 and a fast driving cylinder 5, and fixing the fast driving cylinder 5 between the fixed template 1 and the movable template 2;

[0028] ② Fix the front ends 31 of the four mold locking tie rods 3 to the four corners of the movable formwork 2 respectively by means of fasteners, and the tail ends 32 of the four mold locking tie rods 3 pass through the four corners of the fixed formwork 1 corner through hole 11;

[0029] ③ After the tail end 32 of the mold clamping tie rod 3 passes through the through hole 11, a piston 6 is sleeved and fixed on the tail end 32 so that the mold clamping tie rod 3 and the piston 6 are fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com