In-tank fuel purifying treatment apparatus

A purification treatment and internal fuel technology, which is applied to fuel injection devices, liquid fuel feeders, internal combustion piston engines, etc., can solve the problems of inability to carry out fuel, troublesome and troublesome, supply or replenishment, etc., and achieve the effect of improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0036] Hereinafter, a first embodiment of the present invention will be described with reference to the drawings.

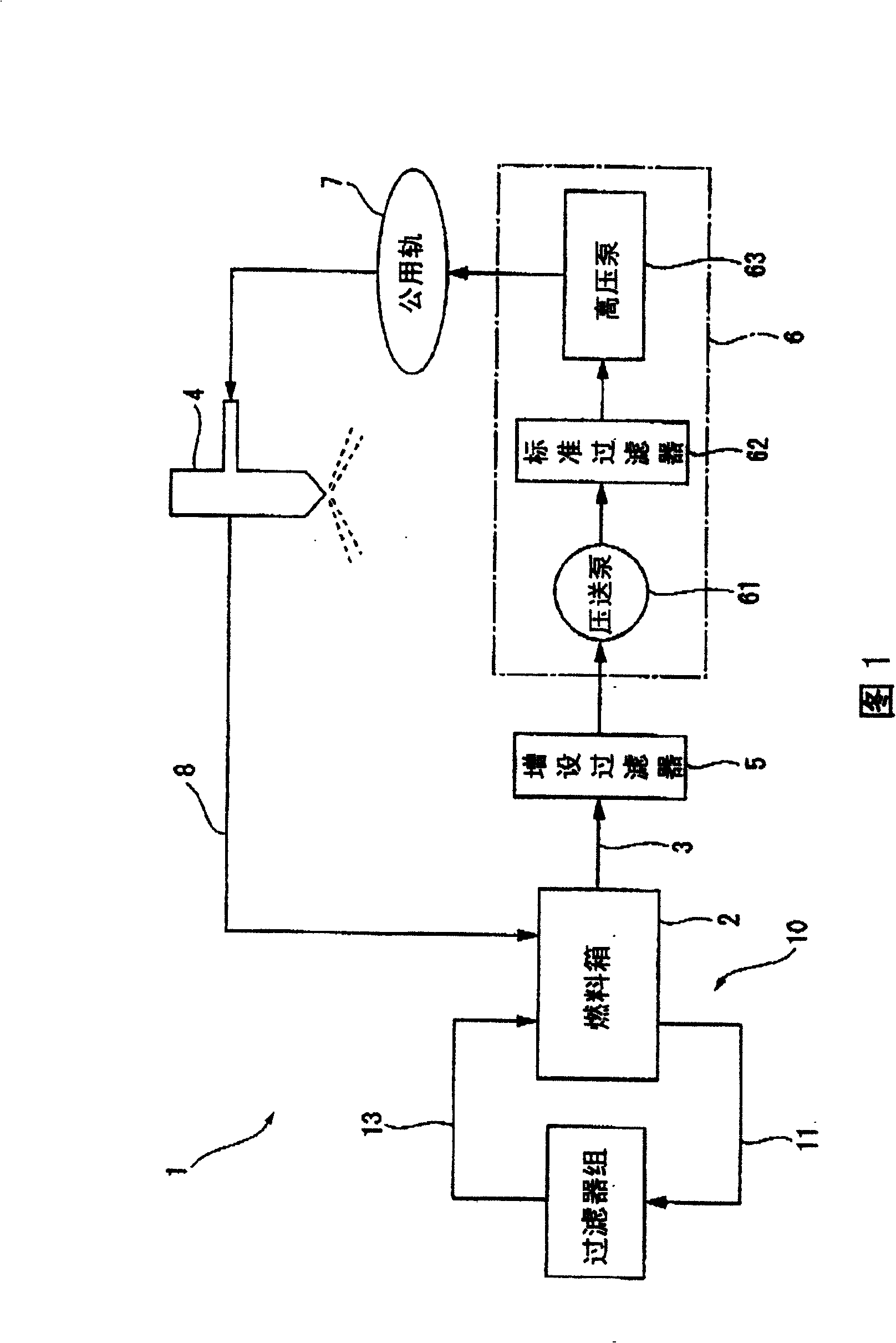

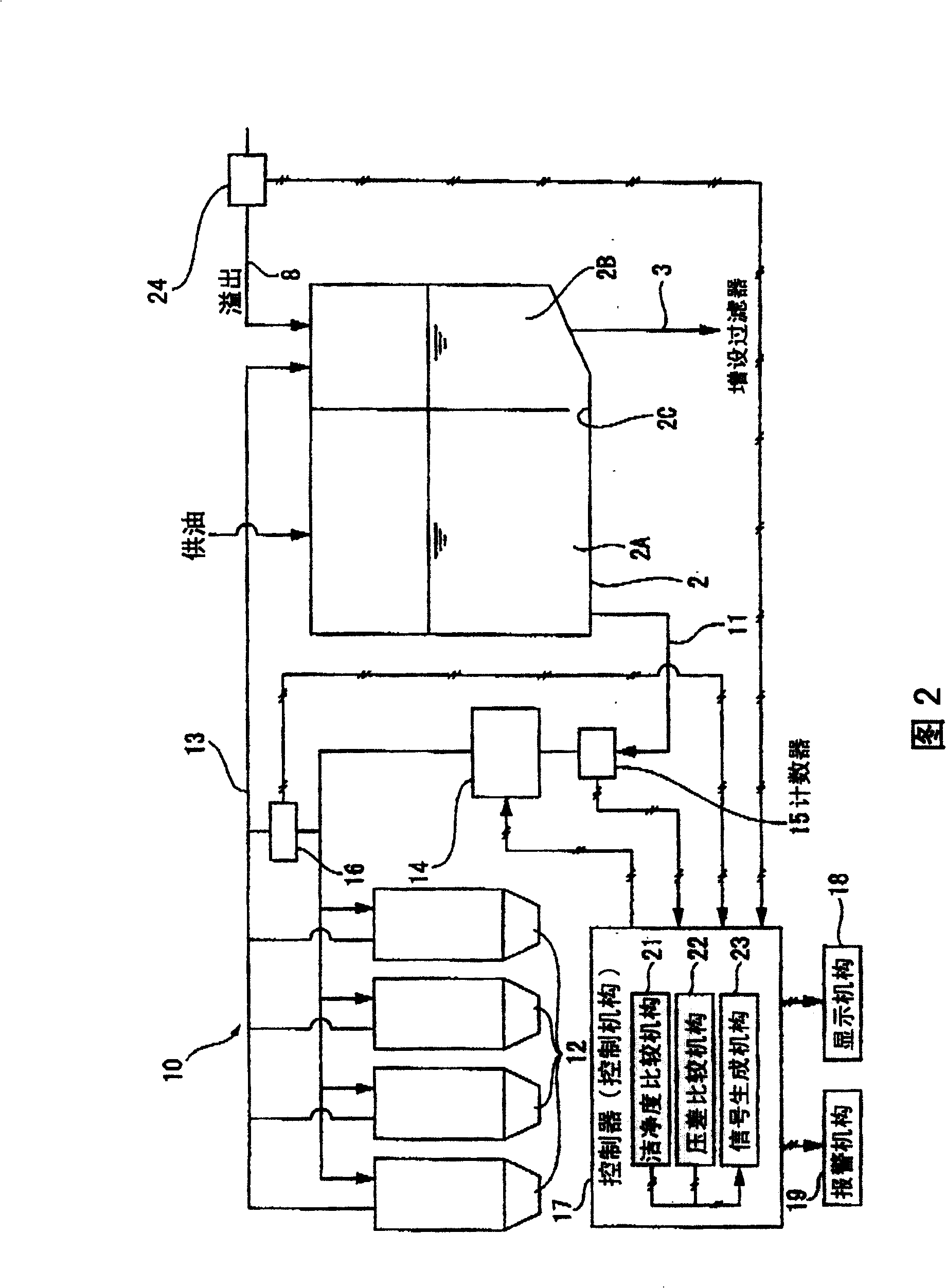

[0037] FIG. 1 is a schematic diagram showing the configuration of main parts of a construction machine 1 such as a hydraulic excavator, a wheel loader, a bulldozer, and a motor grader to which an in-tank fuel purification treatment device 10 according to the present embodiment is applied.

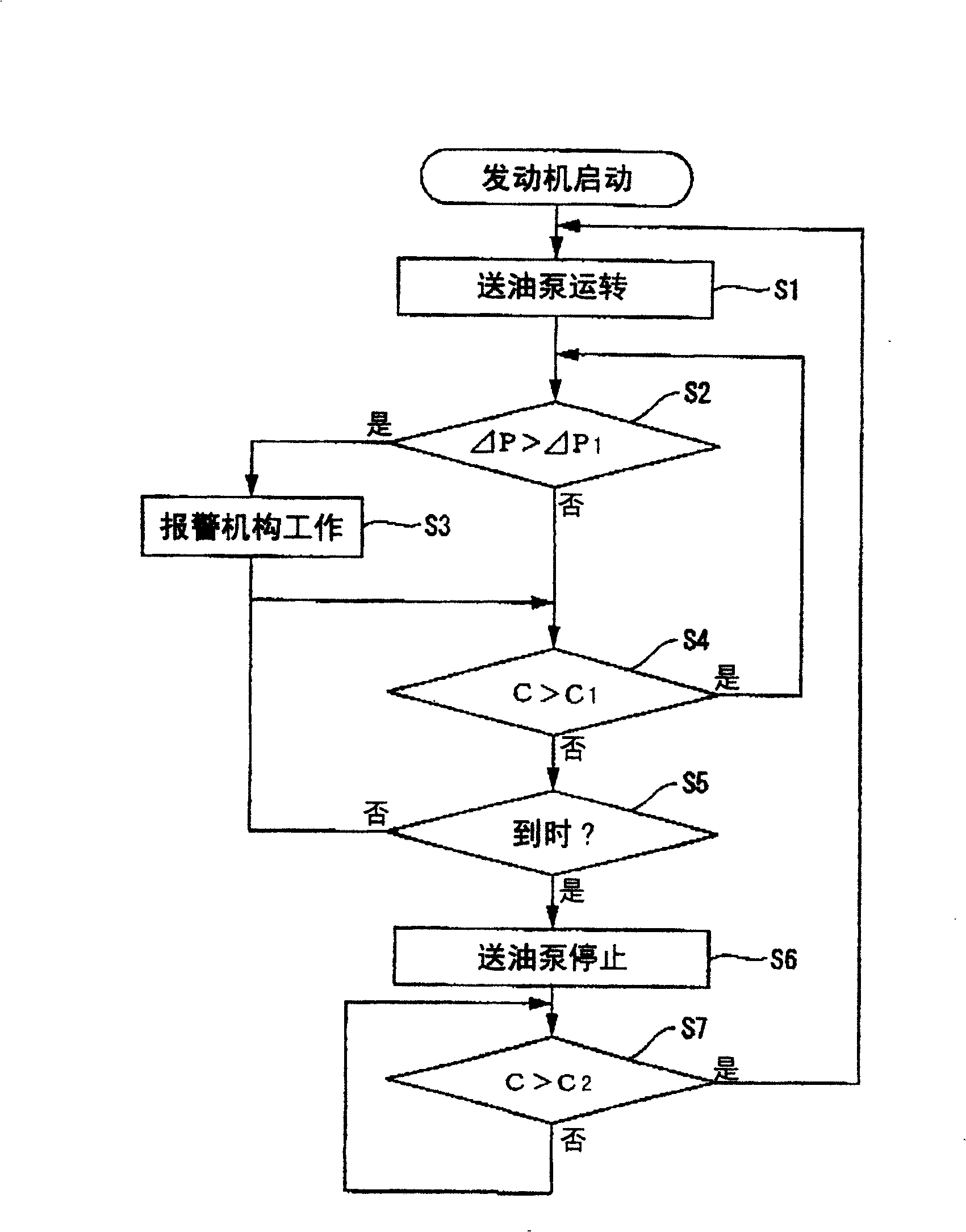

[0038] First, in this construction machine 1, the fuel stored in the fuel tank 2 is supplied to the fuel injection device 4 through the supply path 3, and then injected into the cylinder of the engine (not shown), as in the general specifications. In the supply path 3, an extension filter 5, a fuel pump 6, and a common rail 7 are provided in this order from the upstream side. In addition, the fuel pump 6 includes a pressure feed pump 61 that draws fuel from the fuel tank 2, a standard filter 62 that purifies the fuel discharged from the pressure feed pump 61, and a high pressure...

no. 2 Embodiment approach

[0078] FIG. 4 is a schematic diagram showing the configuration of main parts of an in-tank fuel purification treatment device 10 according to a second embodiment of the present invention.

[0079] In the above-mentioned first embodiment, the fuel tank 2 is divided into the first container portion 2A and the second container portion 2B, but in this embodiment, the sub-tank 30 is provided on the lower side of the normal fuel tank 2 . The supply path 3 is connected to the sub tank 30 .

[0080] In addition, by providing a switching valve 31 on the fuel delivery path 11 connected to the fuel tank 2, switching operation is performed according to a switching signal from the controller 17, and switching is made between the fuel flow to the particle counter 15 ( FIG. 2 ) side and the secondary fuel flow. Case 30 side flow.

[0081] In addition, the flow of fuel from the fuel tank 2 to the sub-tank 30 is not performed by a pump or the like, but the natural drop of the head pressure is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com