Air cleaner

An air filter and air technology, applied in the fields of dispersed particle filtration, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of blockage of element mesh, easy pressure loss, inappropriate structure, etc., to increase the passage. The effect of small area and via resistance and large via area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0038]Next, a first embodiment of the present invention will be described with reference to the drawings. In addition, in the second embodiment and below, the same reference numerals are assigned to the same components and functions as those in the first embodiment described below, and descriptions of these components in the second embodiment and below are omitted or simplified.

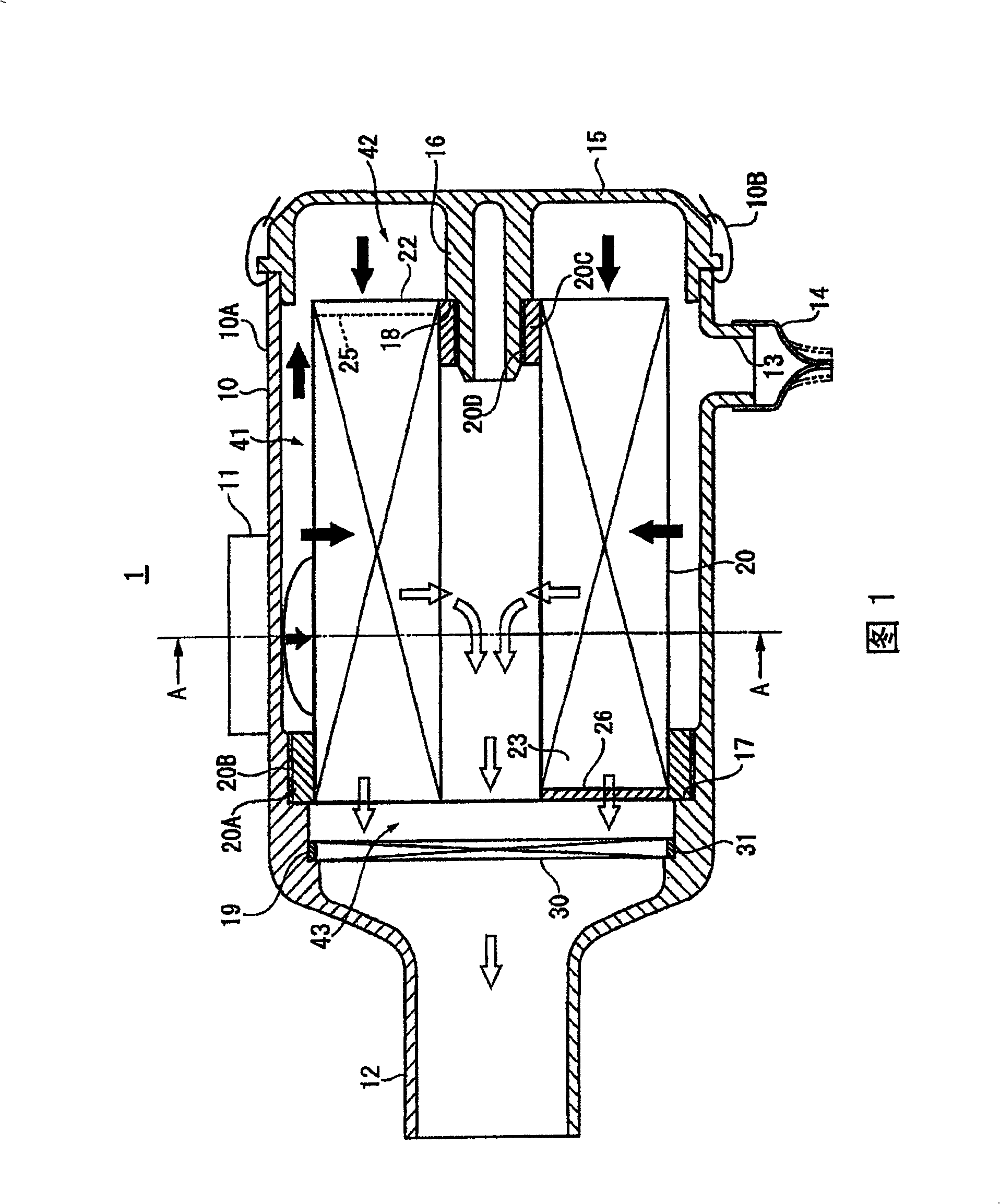

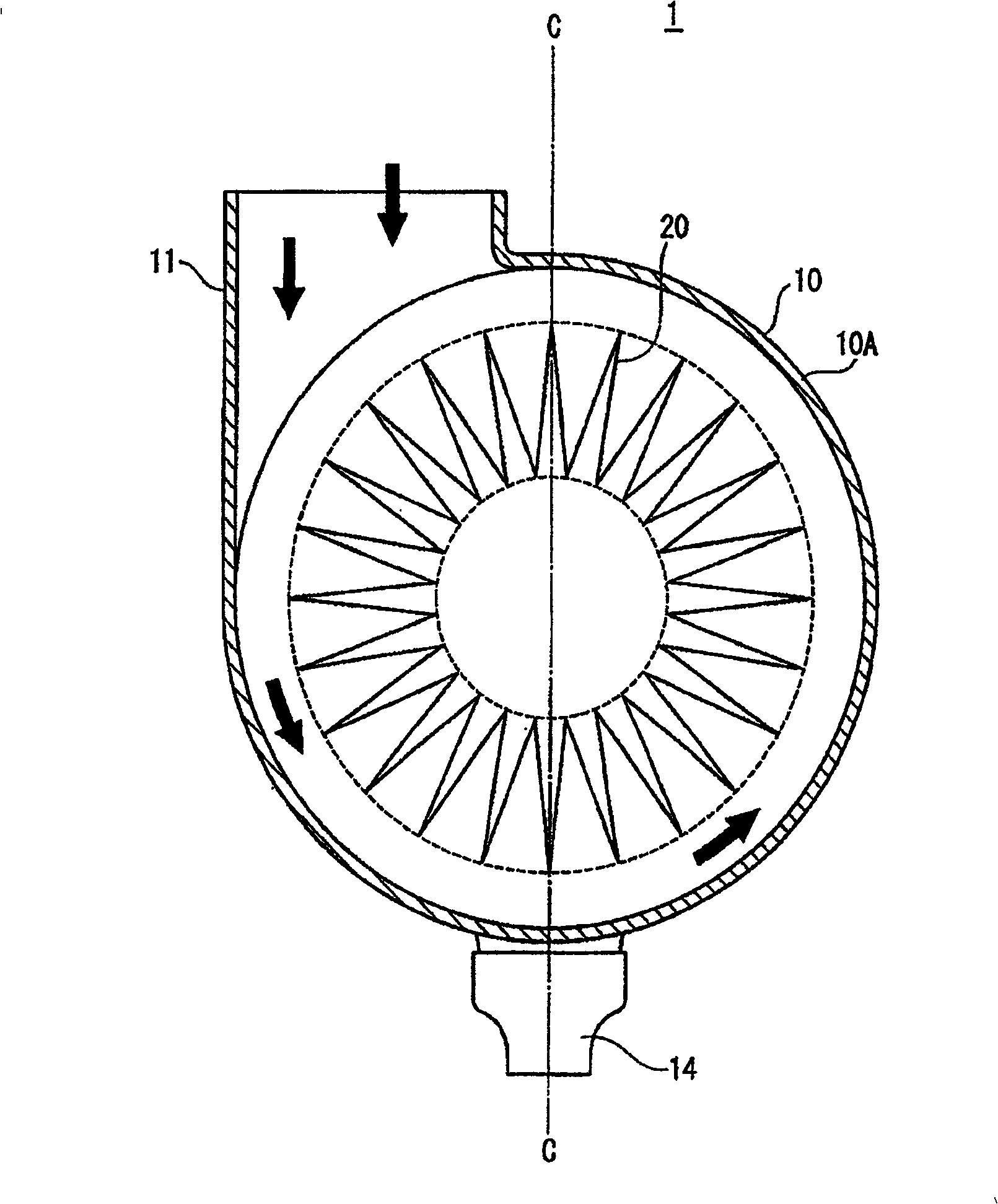

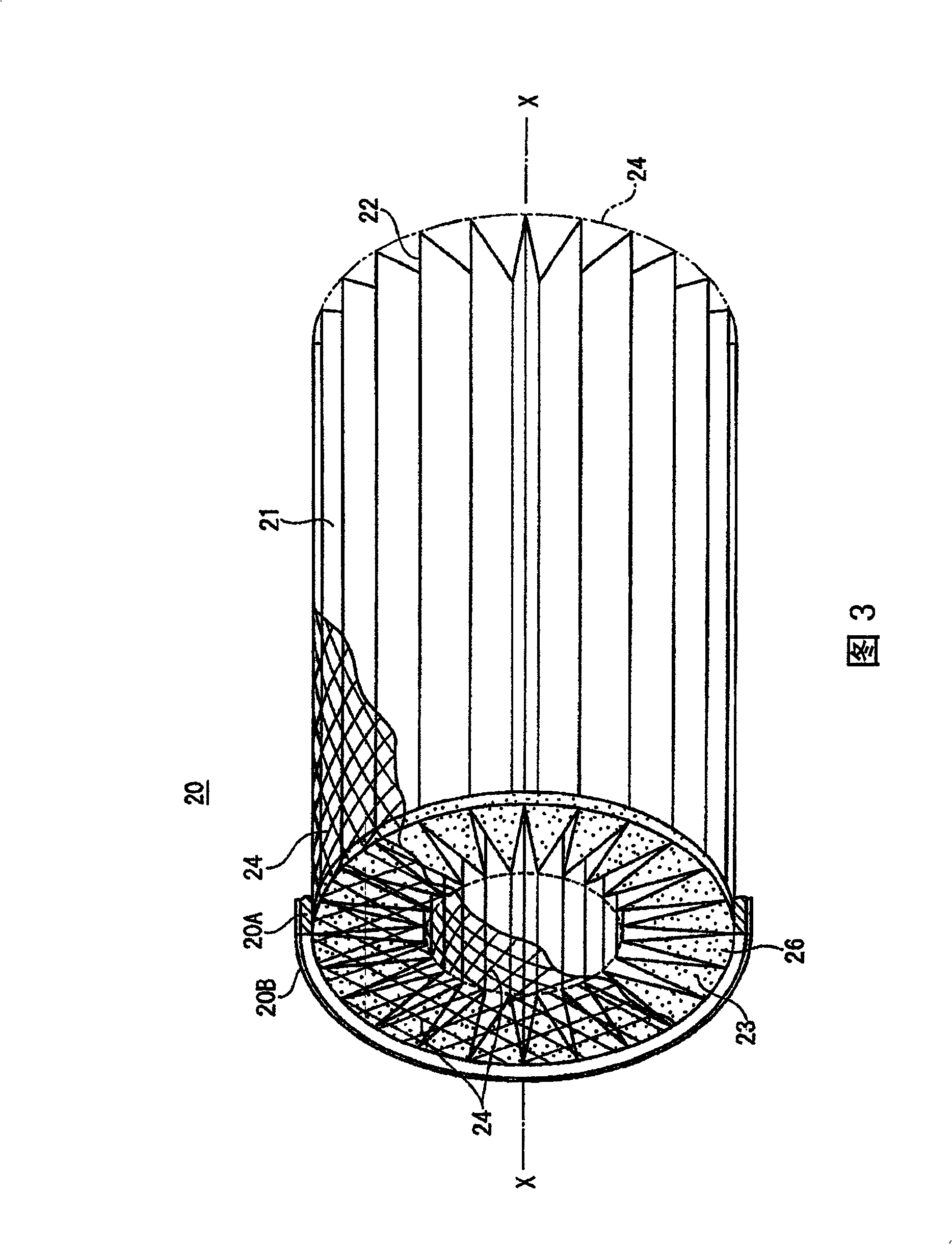

[0039] FIG. 1 shows a cross-sectional view of an air filter 1 according to a first embodiment. figure 2 It is the A-A line view of Fig. 1 .

[0040] In Figure 1, figure 2 Among them, the air filter 1 is a device mounted on a construction machine that works on a sandy and dusty construction site, etc., and includes: a cylindrical casing 10 having a casing main body 10A that is open at one end; A filter element 20 inside; a safety filter (safety filter) 30 disposed on the downstream side of the filter element 20 in the same casing 10 .

[0041] The outer peripheral part of the casing 10, on the ...

no. 2 Embodiment approach

[0062] Fig. 7 is a cross-sectional view of an air filter 2 according to a second embodiment of the present invention. Figure 8 It is a sectional view taken along line VIII-VIII in FIG. 7 .

[0063] In Figure 7, Figure 8 In the air filter 2 shown in , in the inner peripheral side of the end portion on the casing 15 side of the casing main body 10A, a support portion 51 that supports the outer peripheral portion of the filter element 20 is provided. The outer peripheral side holding member 61 is bonded to the outer peripheral portion of the filter element 20 , and when the filter element 20 is stored in the cabinet 10 , the outer peripheral side holding member 61 abuts against the support portion 51 to hold one end of the filter element 20 . The end portion of the casing body 10A side of the casing 15 is provided with a butt joint 52, and when the casing 15 is installed in the casing body 10A, the butt joint 52 abuts with the side surface of the outer peripheral side holding ...

no. 3 Embodiment approach

[0066] In the air filter 3 of the third embodiment shown in FIG. 9 , the shapes of the casing 10 and the filter element 20 are largely different from those of the first and second embodiments.

[0067] That is, the casing main body 10A of the casing 10 in this embodiment is substantially box-shaped with an upper side open, and the air output duct 12 is provided on the lower side of the casing 10 . In addition, an air inlet pipe 11 is provided on the casing 15 to close the opening of the casing main body 10A.

[0068]Inside the casing 10, a housing portion 53 for housing the rectangular parallelepiped filter element 20 is provided. In the accommodating portion 53, set: the upper side opening 54 that is used to drop into the filter element 20 from above; the lower side opening 55 that the filtered air flows out from below; The opposite inlet-side opening portion 56 and the outlet-side opening portion 57 opposite to the open end portion of the peak portion 22 .

[0069] In addi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com