Metal filtering core and production thereof

A technology of metal filter elements and manufacturing methods, applied in separation methods, chemical instruments and methods, and dispersed particle filtration, etc., can solve problems such as poor resistance to shock and vibration, inability to increase the ratio, anisotropy of physical parameters, etc., and achieve effective The effect of interception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

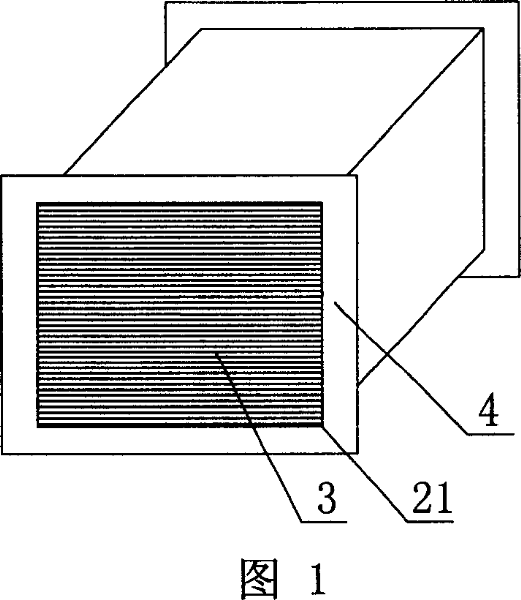

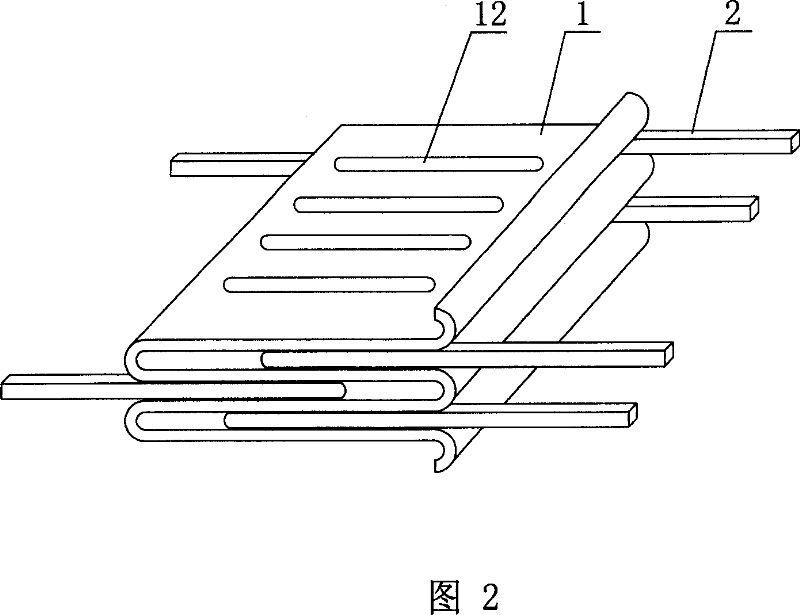

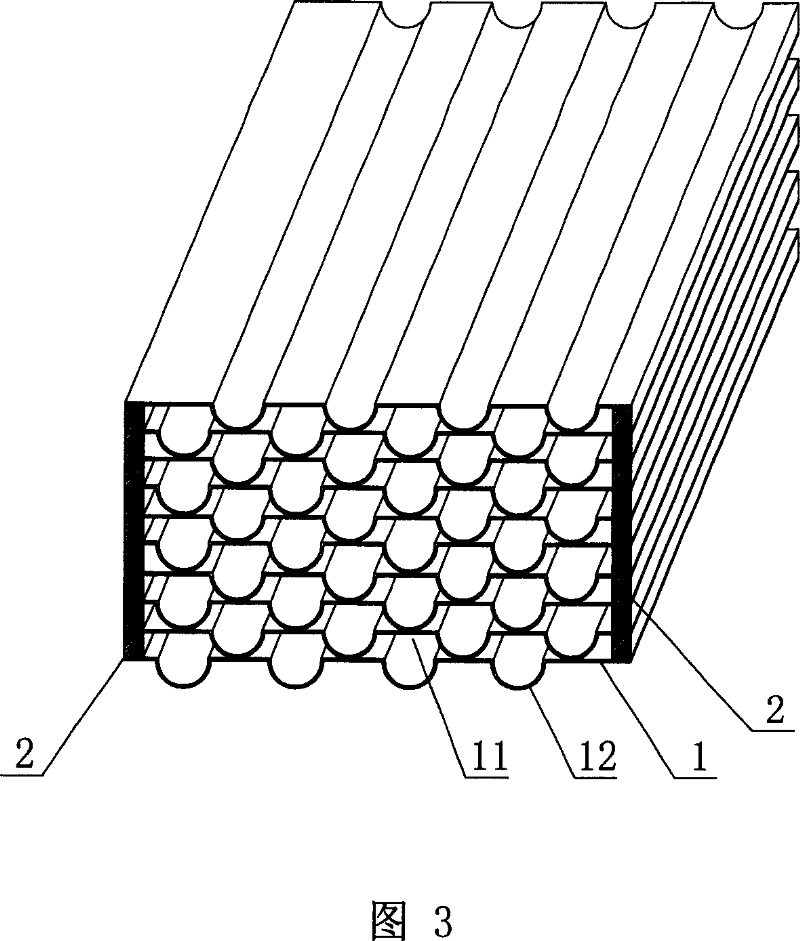

[0028] As shown in Figures 1 to 4, a metal filter element according to the present invention includes:

[0029] A group of filter element units folded, welded and compacted by multi-layer porous metal strips 1 and metal strips 2 packaged on both ends of the filter element group in the direction of the vertical welding seam, wherein the surfaces of two adjacent layers of porous metal strips 1 are respectively pressed There are columnar support channels 12 that are mutually misaligned and can support each other, and the space formed by two adjacent columnar support channels 12 between adjacent two porous metal strips 1 can capture and remove the exhaust gas contained in diesel engines. Exhaust gas filter channel 11 for black smoke particles.

[0030] The manufacture method of metal filter element of the present invention, comprises the following steps:

[0031] Step 1, the metal powder, binder and wire mesh are coated, sintered, and rolled to make a porous metal strip 1; at thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com