Image quality prediction method and apparatus and fault diagnosis system

A technology of image quality and prediction method, which is applied in the field of fault diagnosis of equipment, design and implementation of fault diagnosis system, can solve problems such as lack of standards and dependence, achieve objective evaluation results, and avoid the effects of subjective factors of experts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

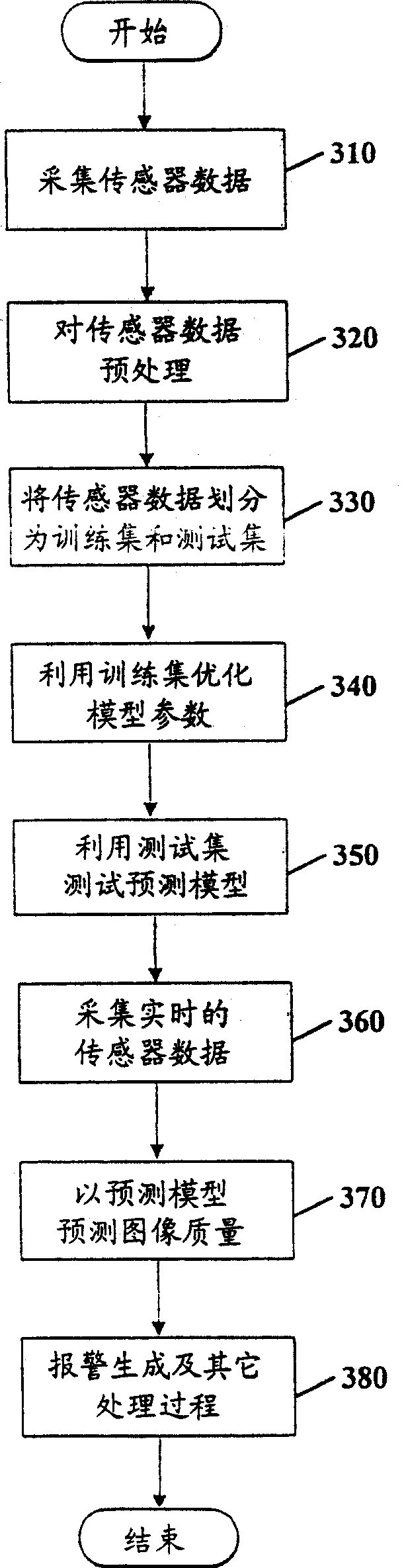

[0031] Generally speaking, the image quality of MFPs can be divided into three categories: vertical defects, horizontal defects and point defects. From the printed image, vertical defects and horizontal defects are vertical or horizontal white lines or dark lines, and point defects are spots with a diameter of about 3 mm. In the present invention, considering that various defects have different degrees of severity, various defects (image quality) are divided into four levels, that is, level 0 is a normal image without defects, level 1 is a slight defect, level 2 Moderate flaws, level 3 serious flaws.

[0032] However, the above four levels do not limit the technical scope of the present invention, and other embodiments of the present invention may adopt other numbers of levels.

[0033] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

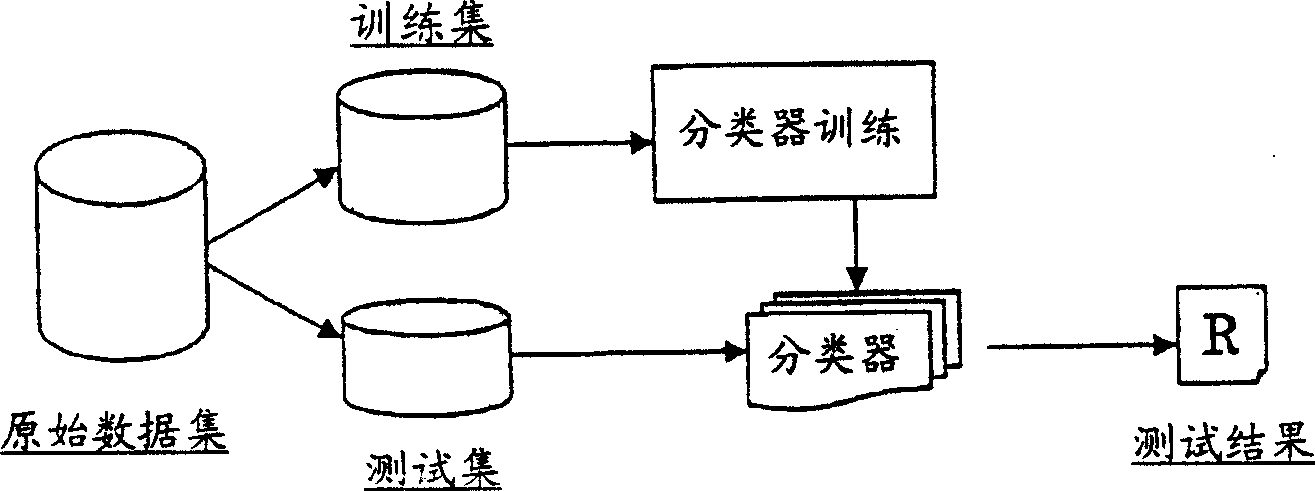

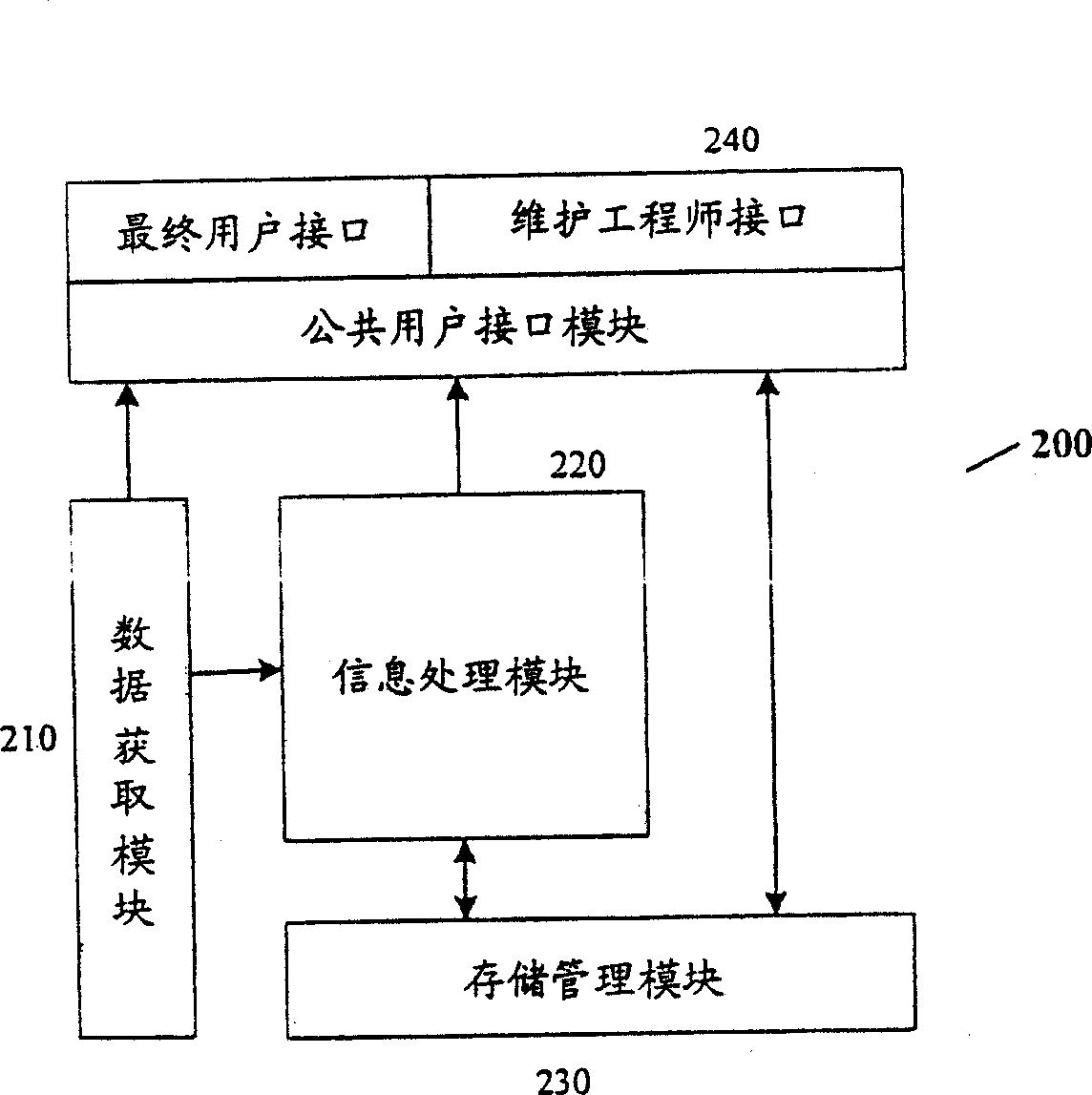

[0034] The basic strategy for predicting image quality in the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com