Cleaning unit and image forming apparatus

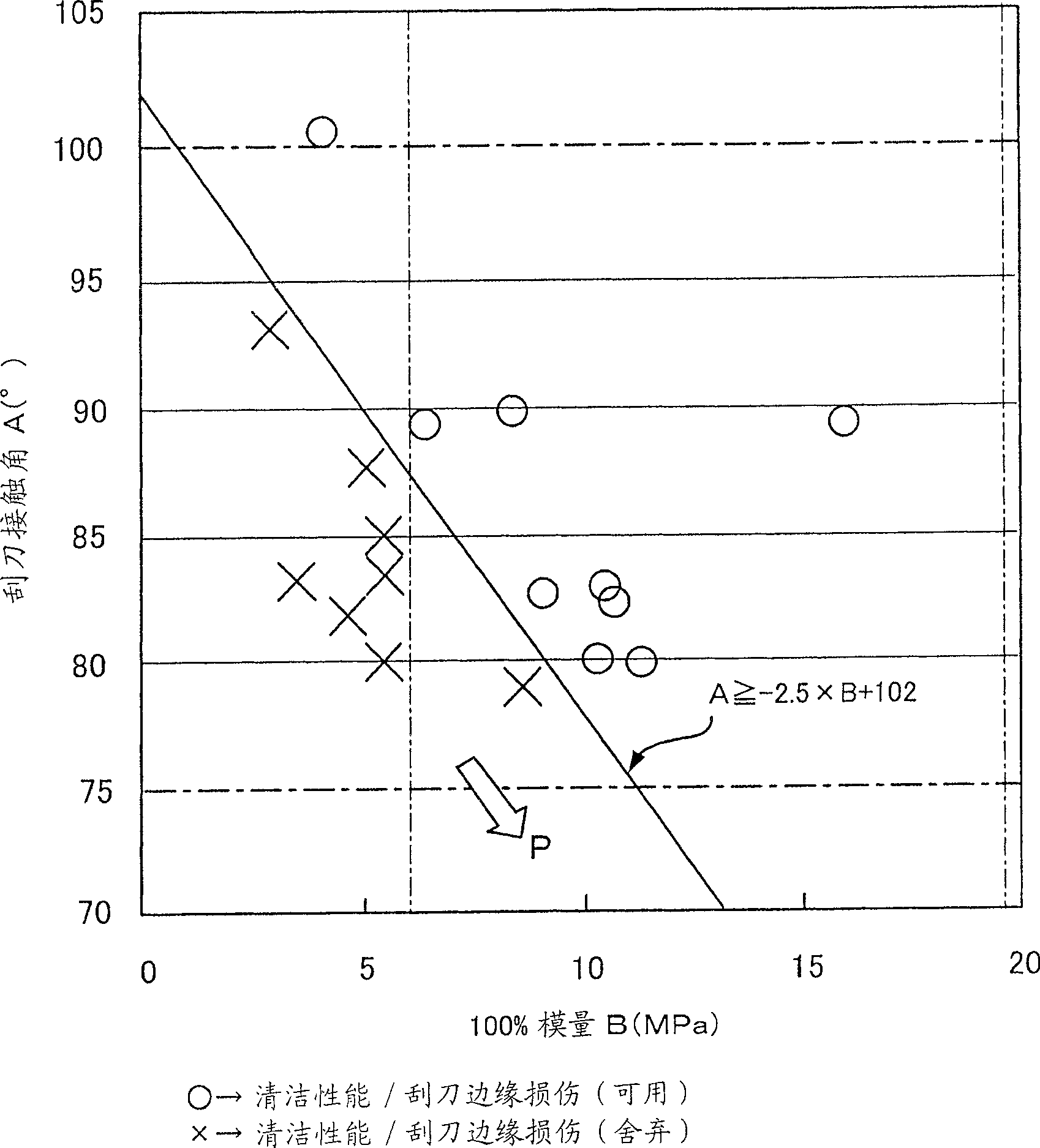

A technology for cleaning units and imaging equipment, applied in the direction of equipment, electrographics, optics, etc. using electric recording technology of charge patterns, to achieve the effects of long service life, suppression of damage, and improvement of cleaning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0263] As a test machine, a modified Fuji Xerox Co., Ltd. Docu-Center Color 500 was used. That is, a photoreceptor A having a protective layer formed on its surface was assembled as a photoreceptor. Assemble the cleaning unit equipped with cleaning blade A and cleaning accessory A. Durability of about 100,000 images was performed at low temperature / low humidity (10°C, 20% relative humidity) and high temperature / high humidity (28°C, 80% relative humidity) using a product developer of Docu-Center Color500 as the developer A resistance test to evaluate wear of the photoreceptor and scratches on the photoreceptor (photoreceptor roughness). In addition, the occurrence of filming at low temperature / low humidity was evaluated, and the image flow at high temperature / high humidity was evaluated. These results are presented in Table 2 together with a comprehensive assessment.

[0264] Table 2

[0265]

[0266] The details of each assessment are as follows.

[0267]...

Embodiment 2~5

[0290] The same tests and evaluations as in Example 1 were performed using the same image forming apparatus as in Example 1 except that the cleaning blade was changed to that shown in Table 2. The results are shown in Table 2.

Embodiment 6~8

[0292] The same tests and evaluations as in Example 1 were performed using the same image forming apparatus as in Example 1 or 2 except that the cleaning blade was changed to that shown in Table 2. The results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com