Sterilizing environmental protection mop cleaning machine

A mop cleaning machine, the function of technology, applied in the field of cleaning machines, can solve the problems of purchase cost, cross-infection, environmental pollution, etc., achieve good decontamination cleaning effect, prevent the spread of germs, and ensure good performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

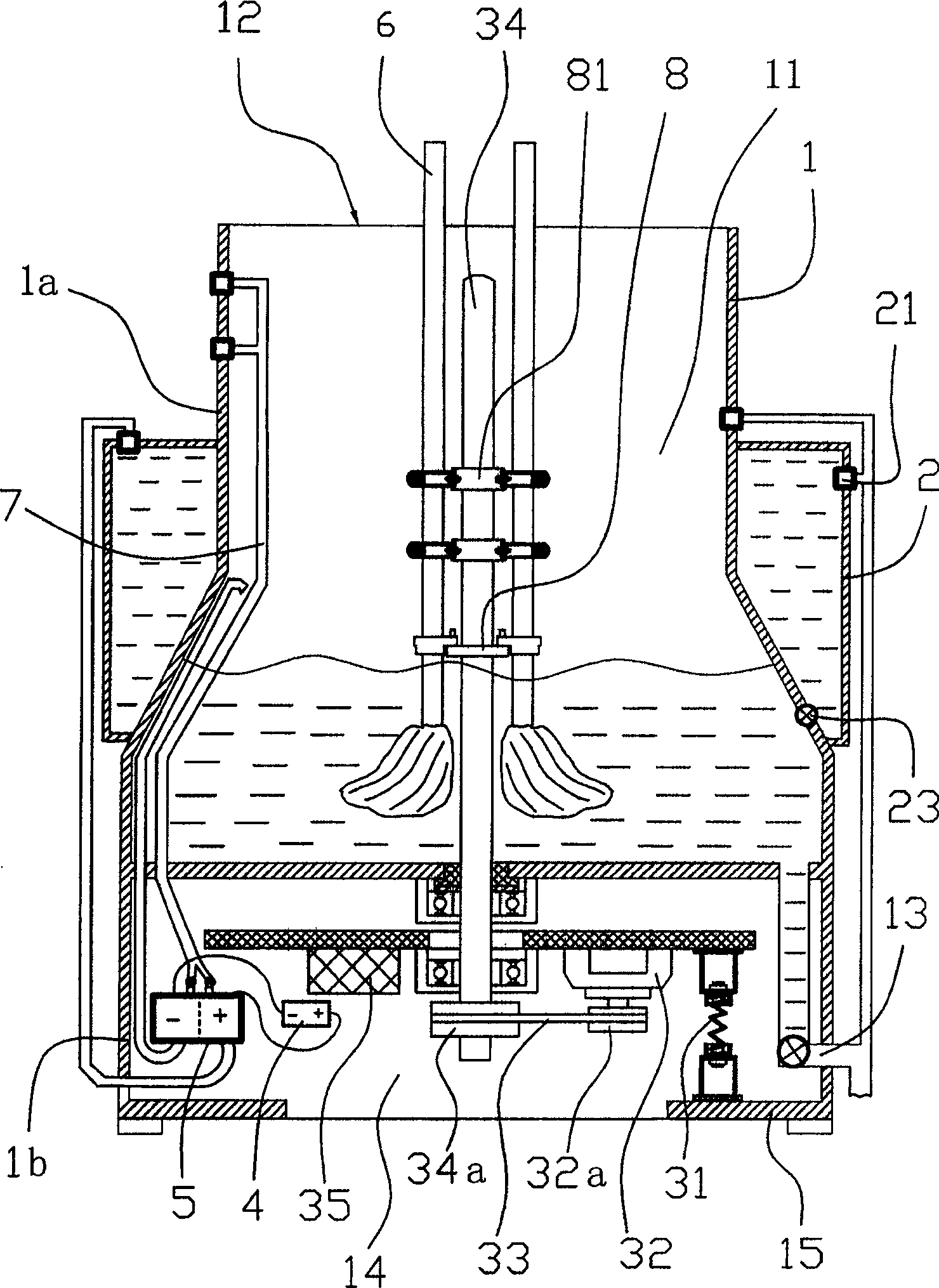

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0013] Such as figure 1 and figure 2 As shown, the mop cleaning machine with sterilization and environmental protection in this embodiment includes a body of the cleaning machine, which includes a barrel body 1, a rotating shaft 34 for fixing the mop 6, and a motor 32. The rotating shaft 34 is rotatably placed in the staving body 1, and a drainage hole 13 is provided in the staving body 1, and the upper end of the staving body 1 is provided with an opening 12 that allows the mop 6 rods to extend out of the staving body 1, the The bucket body 1 is divided into an upper part 1a and a lower part 1b. The upper part 1a and the lower part 2b adopt an integral structure of injection molding. Of course, the upper part 1a and the lower part 2b of the bucket body 1 can also be composed of two parts, which can be determined according to the design and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com