automatic shoe washing machine

A shoe washing machine, automatic technology, applied in the field of shoe washing machines, can solve the problems of long drying time, troublesome, unclean brushing, etc., achieve good decontamination cleaning effect, avoid cross-contamination, and reduce labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

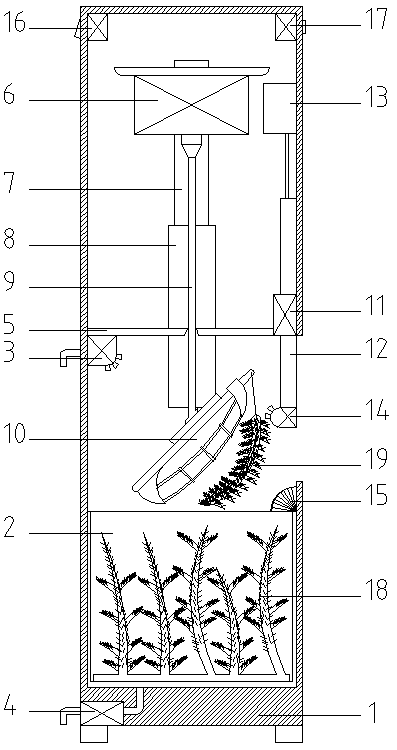

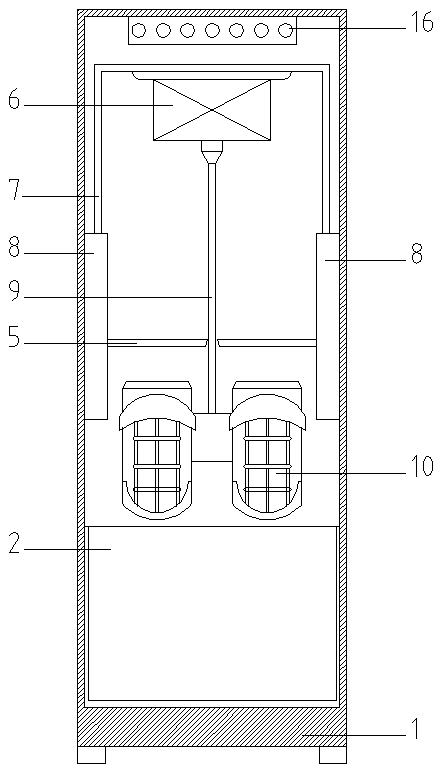

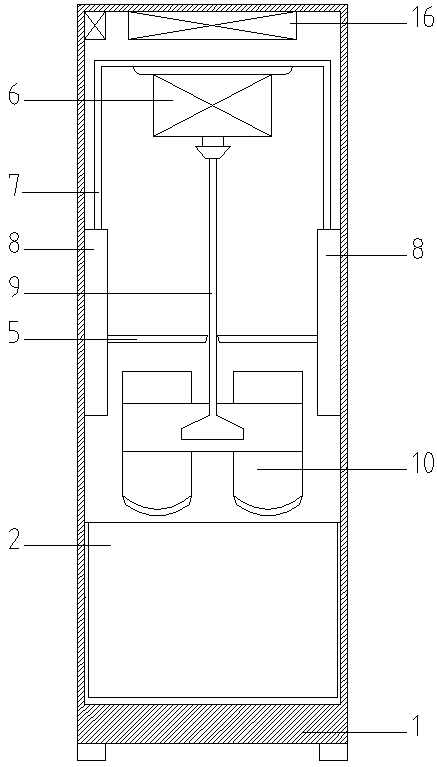

[0021] Such as figure 1 figure 2 image 3 As shown, it has the functions of automatic soaking and cleaning and automatic dry control. It is lifted by the shell 1, the water tank 2, the water inlet control unit 3, the drainage control unit 4, the partition 5, the driving motor 6, the motor fixing frame 7, and the motor fixing frame. 8, transmission rod 9, shoe rack 10, door stop lifter 11, door stop 12, detergent storage tank 13, detergent nozzle 14, sterilizing / drying lamp 15, intelligent control unit 16, power control unit 17, The branch brush 18 and the strip brush 19 are composed of the water tank 2, the water inlet control unit 3, the drainage control unit 4, the clapboard 5, the motor fixing frame lifter 8, the door stop lifter 11, the detergent storage tank 13, the sterilization / The drying lamp 15, the intelligent control unit 16 and the power control unit 17 are all installed on the housing 1, the driving motor 6 is installed on the motor fixing frame 7, the motor f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com