Improved preparation process of 8-chlorotheophylline

A chlorotheophylline and process technology, applied in the field of pharmaceutical chemical intermediates, can solve the problems of 8-chlorotheophylline, such as unsatisfactory quality, high labor intensity of workers, and harsh operating environment, so as to reduce fixed asset costs and shorten the production cycle , The effect of improving the operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

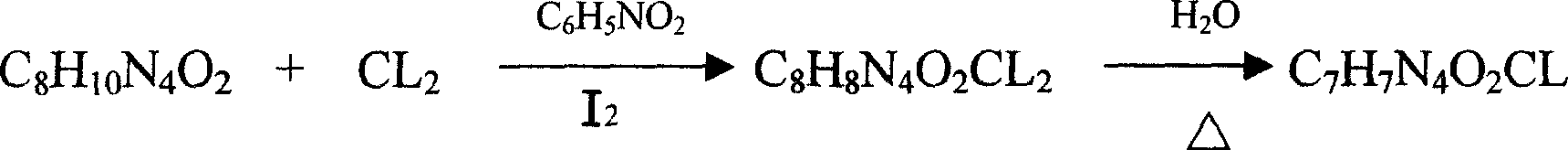

[0032] Taking the 8-chlorotheophylline production plant with an annual production scale of 50 tons as an example, the production process is shown in Figure 2, and the relevant production operations are as follows:

[0033] 1. The chlorination process is an existing technology;

[0034] 2. The process of steaming nitrobenzene is also a prior art;

[0035] 3. Purification process

[0036] 3.1. The material liquid after chlorination and steaming of nitrobenzene is added to the purification tank, and the proportion of the material is shown in Table 3.

[0037] table 3

[0038] raw material name Proportion (weight ratio) Feeding amount Raw material specification 7,8-Dichlorocaffeine 1 60-80kg Decomposition point above 293°C pure water 12 720-960L Clarity, transparency, no impurities

sodium hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com