A biomass straw instantaneous combination collection forming machine

A biomass straw and forming machine technology, which is applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems of large investment in rolling forming, fast wear of parts, low output rate, etc., and achieves a wide range of applications , high efficiency and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

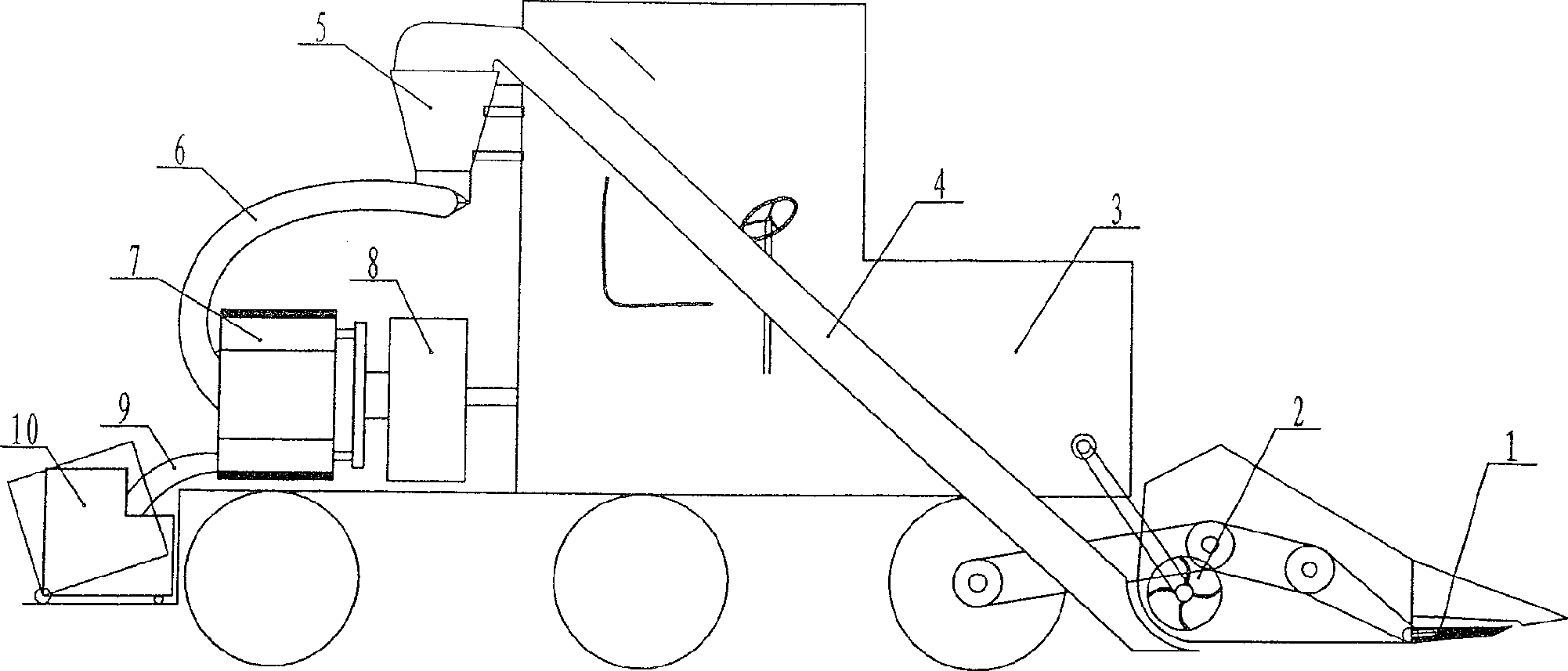

[0036] figure 1 Among them, the front portion of the tractor 3 is equipped with a collection device 1 and a straw crushing device 2, and the straw crushing device 2 is connected with the dust removal device 5 located above the rear of the tractor 3 through the wind power transmission device I4, and the dust removal device 5 is connected with the dust removal device 5 through the wind power transmission device II 6 The straw forming mechanism 7 located under the rear part of the tractor 3 is connected, the power input device of the straw forming mechanism 7 is connected with the power device of the tractor 3 through the reduction device 8, and the output device of the straw forming mechanism 7 is connected with the forming bar material through the forming bar material conveying device 9 The collector 10 is connected.

[0037] The power source of the equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com