Common rail

A technology of common rail and metal base, applied in the field of combined common rail, can solve the problem of difficulty in manufacturing high-precision combined common rail, and achieve the effect of increasing cost and ensuring joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

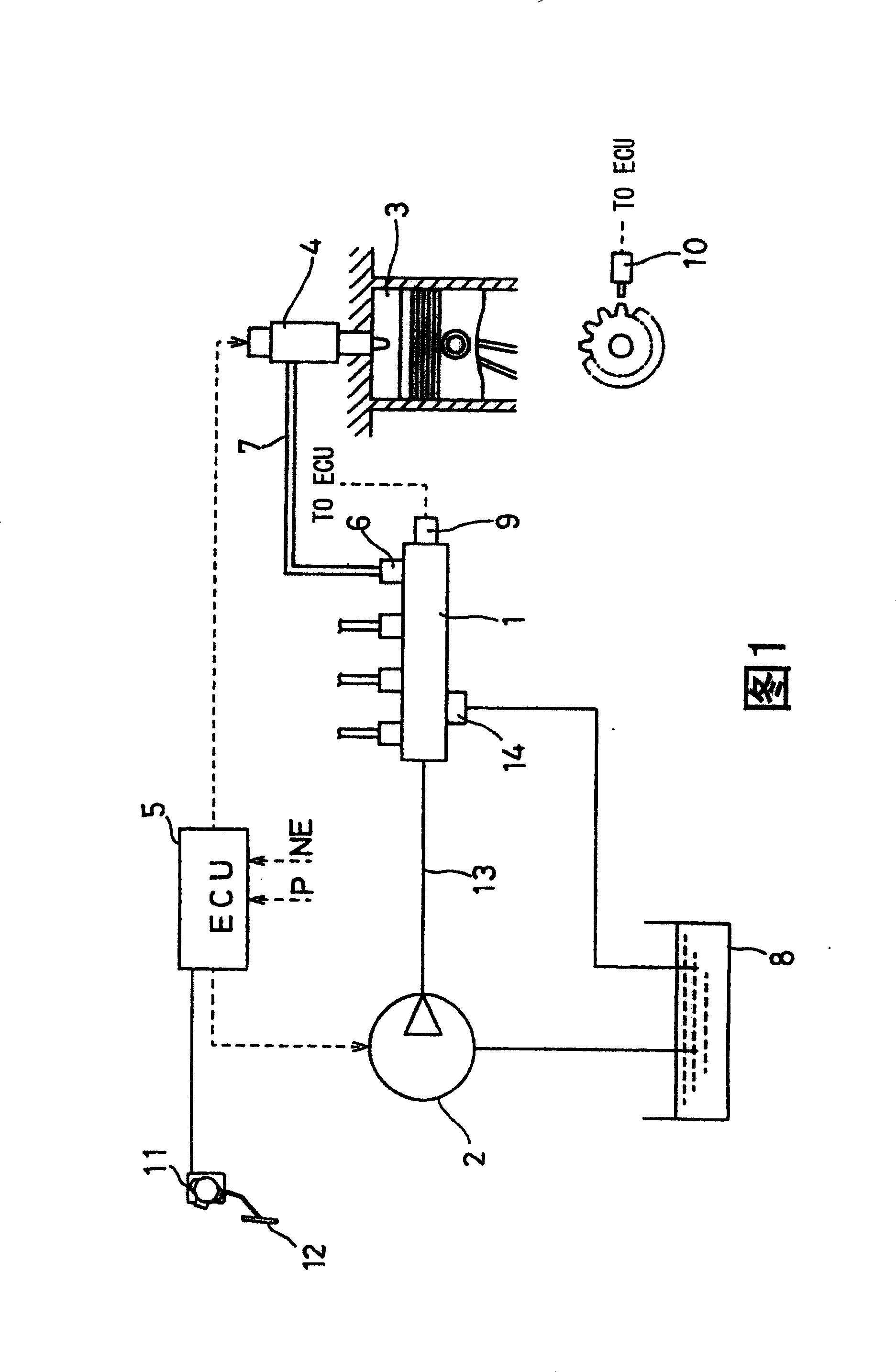

[0070] Referring to FIG. 1, there is shown an accumulator fuel injection system in accordance with a first example embodiment of the present invention.

[0071] For example, the accumulator fuel injection system according to the first embodiment is applied to a four-cylinder diesel engine. As shown in FIG. 1, the fuel injection system has a common rail 1 that stores fuel, a fuel supply pump 2 that pressure-supplies fuel to the common rail 1, and at least one (four cylinders in this embodiment) that inject fuel into a diesel engine. ) injector 4 and so on. An electronic control unit (ECU) 5 controls the fuel injection system.

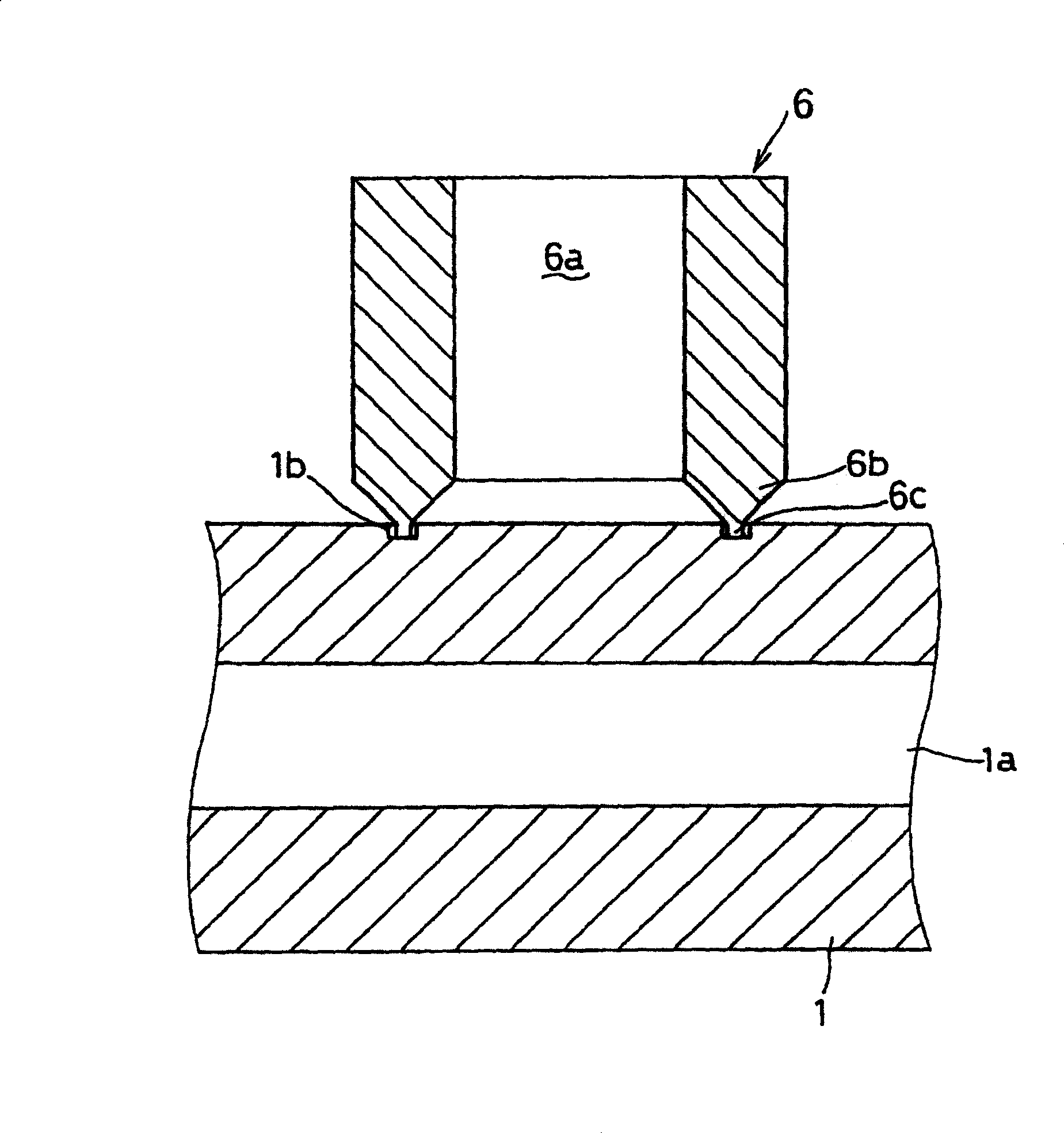

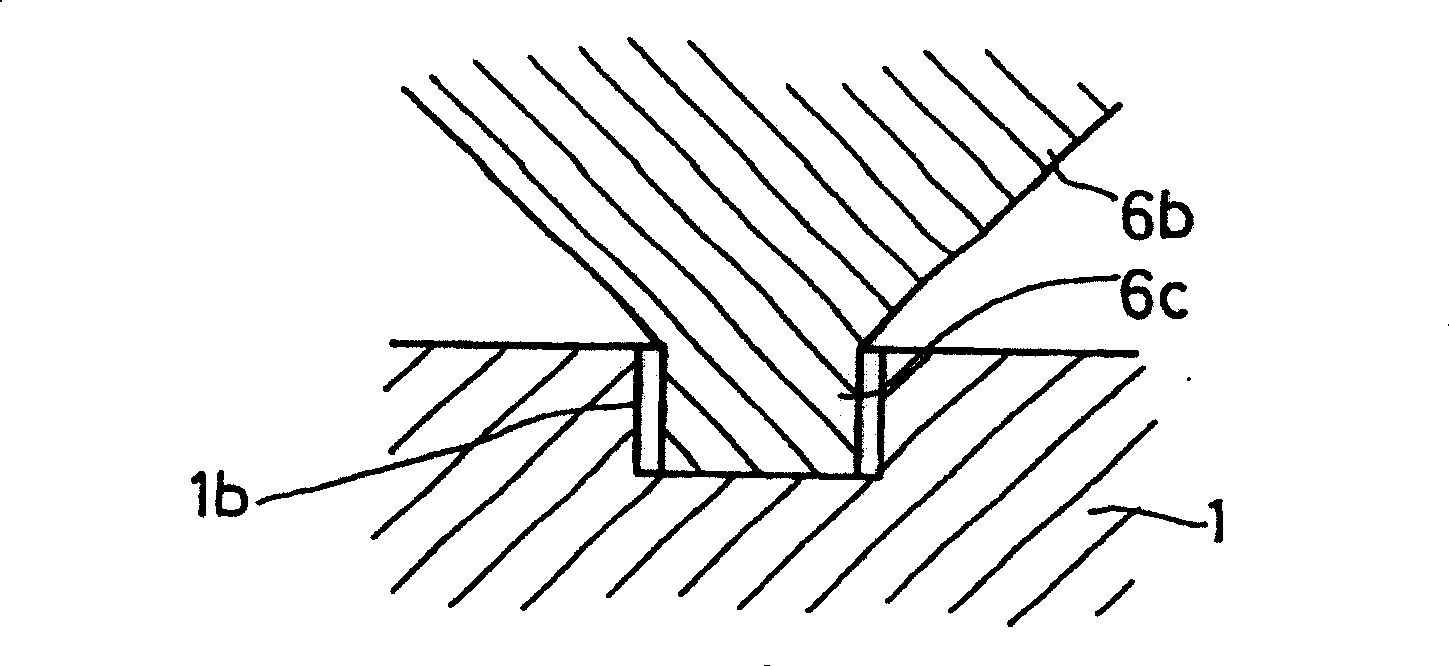

[0072] The common rail 1 accumulates the fuel supplied by the fuel supply pump 2 up to the injection pressure (target rail pressure). The ECU 5 calculates the target rail pressure in accordance with the operating state of the engine (for example, accelerator position and engine speed). The common rail 1 is formed with the same number of pipe connector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com