Golden thickening printed cotton cloth and forming tech. thereof

A technology of printed cloth and gold paste, applied in dyeing method, textile and papermaking, etc., can solve the problems of no crack resistance, high temperature resistance, pattern damage, etc., to achieve warm and brilliant visual effects, improve internal quality, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

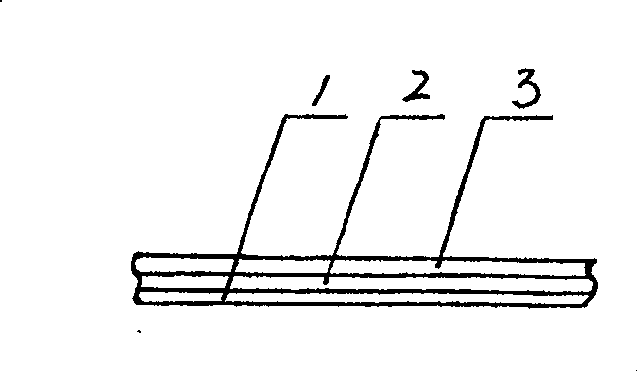

[0009] Embodiment 1: with reference to attached figure 1 . Gold paste calico, it comprises cloth 1, and cloth 1 is velvet fabric (such as brocade velvet, velvet, silk velvet) or home textile fabric (such as cotton cloth or knitting or silk or chemical fiber or wool spinning), and its manufacturing process is the prior art , not described here. The printing position in the cloth 1 is composed of the cloth 1, the bottom layer 2 and the gold paste color layer 3. The bottom layer 2 is a soft layer with elasticity, such as a high elastic pulp layer and made of a polymer material, a polymer with elasticity and softness. The material is a prior art, so it will not be described here. Bottom layer 2 is positioned at the printing position of cloth 1, and gold paste color layer 3 is positioned on bottom layer 2, and gold paste color layer 3 is gold pink or printing color and the craft system of preparation is prior art, as gold powder printing.

Embodiment 2

[0010] Embodiment 2: On the basis of embodiment 1, gold paste printing cloth molding process, it comprises cloth 1, at first on the printing position of cloth 1, one layer of high elastic paste is set and forms bottom layer 2, then the required color Gold paste pattern 3 is printed on bottom layer 2.

Embodiment 3

[0011] Embodiment 3: On the basis of Embodiment 2, when the gold paste color layer 3 is recolored, it is printed in stages using the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com