Multi-core electric filling structure for large out light hole vertical cavity surface emitting semiconductor laser

A vertical cavity surface emission and semiconductor technology, which is applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problems of strong light in the light hole, low light intensity, and excessive current in the light hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

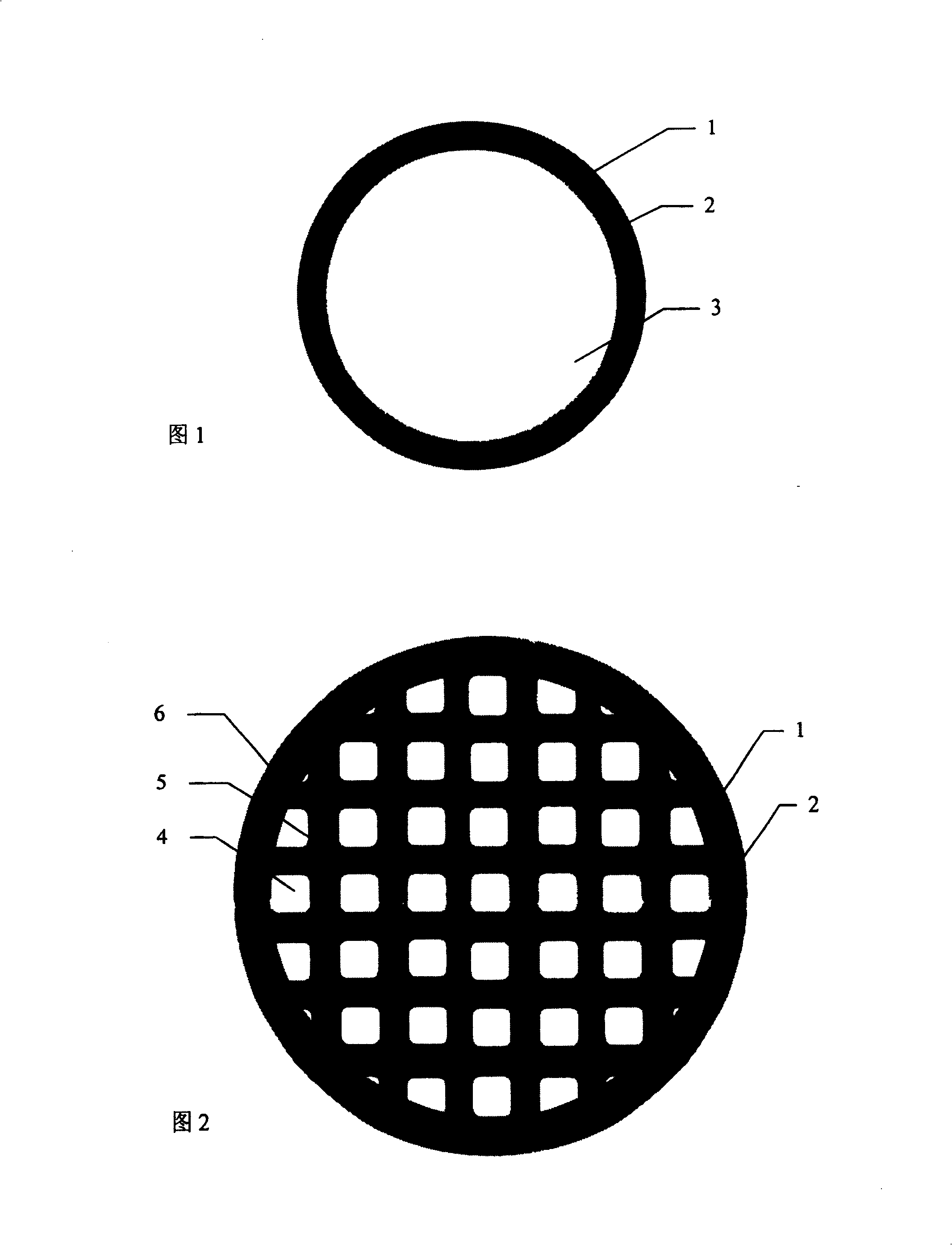

Embodiment 1

[0007] Embodiment 1: As shown in Figure 2, the multi-core electric injection structure of the vertical cavity surface emitting semiconductor laser with large light exit hole is located in the high aluminum layer in the Bragg reflector; in the annular groove 1 and the oxide confinement region 2 on both sides Several discrete current injection regions 4 are evenly distributed in the enclosed area; these discrete current injection regions 4 are separated by a plurality of linear trenches 5 distributed in the region and oxide confinement regions 6 on both sides; the linear trenches The bottom of 5 is the same as the bottom of annular groove 1, and penetrates the high aluminum layer in the depth direction; the oxide confinement regions 6 on both sides of linear groove 5 are the same as the oxide confinement regions 2 on both sides of annular groove 1 The same, all are at the high aluminum layer level; these linear grooves 5 and the oxide confinement regions 6 on both sides are in th...

Embodiment 2

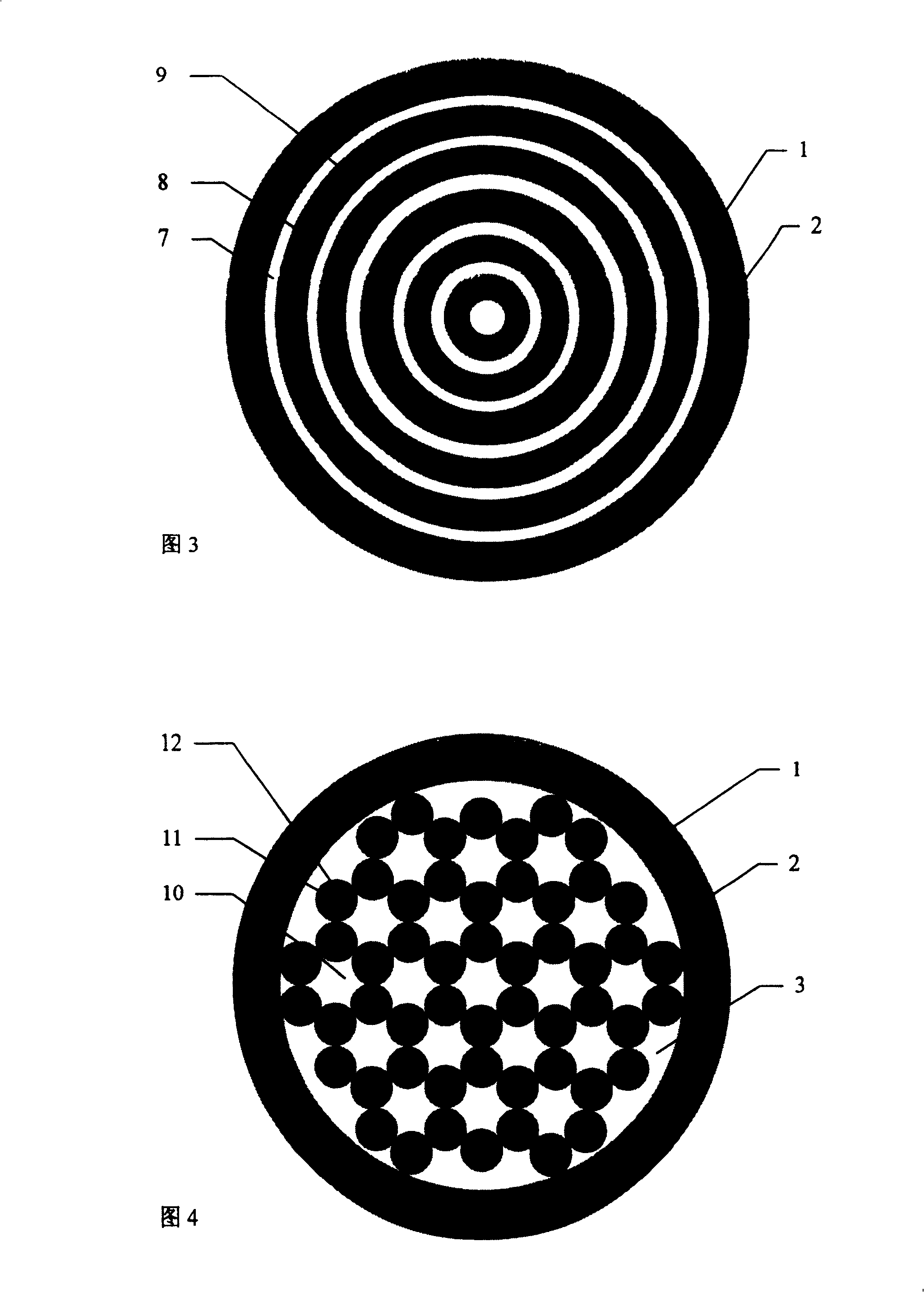

[0008] Embodiment 2; as shown in Figure 3, the multi-core electric injection structure of the vertical cavity surface emitting semiconductor laser with large light exit is located in the high aluminum layer in the Bragg reflector; in the annular groove 1 and the oxide confinement region 2 on both sides A number of discrete current injection regions 7 are evenly distributed in the enclosed area; these discrete current injection regions 7 are separated by a plurality of annular grooves 8 distributed in the region and oxide confinement regions 9 on both sides; the annular grooves The bottom of 8 is the same as the bottom of the annular groove 1, and penetrates the high aluminum layer in the depth direction; same, all at the level of the high aluminum layer; these annular grooves 8 and the oxide confinement regions 9 on both sides are in the shape of concentric rings; the discrete current injection regions 7 are rings with different calibers, and they The rings are evenly distribu...

Embodiment 3

[0009] Embodiment 3: As shown in Figure 4, the multi-core electric injection structure of the vertical cavity surface-emitting semiconductor laser with large light exit hole is located in the high aluminum layer in the Bragg reflector; in the annular groove 1 and the oxide confinement region 2 on both sides Several discrete current injection regions 10 are evenly distributed in the enclosed area 3; these discrete current injection regions 10 are separated by a plurality of holes 11 distributed in the region 3 and oxide confinement regions 12 around them; the bottom of the holes 11 Like the bottom of the annular groove 1, it penetrates through the high aluminum layer in the depth direction; the oxide confinement region 12 around the hole 11 is the same as the oxide confinement region 2 on both sides of the annular groove 1, and is located at the same place. The above-mentioned high-aluminum layer levels are connected to each other; these holes 11 and the oxide confinement region...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com