Distilling path dredger on cold end reactor large lid for producing sponge titanium

A technology of dredge and cooling water jacket, applied in the field of non-ferrous metal smelting, can solve the problems of high labor intensity, affecting the production cycle, energy consumption, etc., and achieve the effect of reducing labor intensity, keeping the channel unblocked, and shortening the production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The implementation of the distillation channel clearer of the present invention will be further described below in conjunction with the above-mentioned examples of drawings.

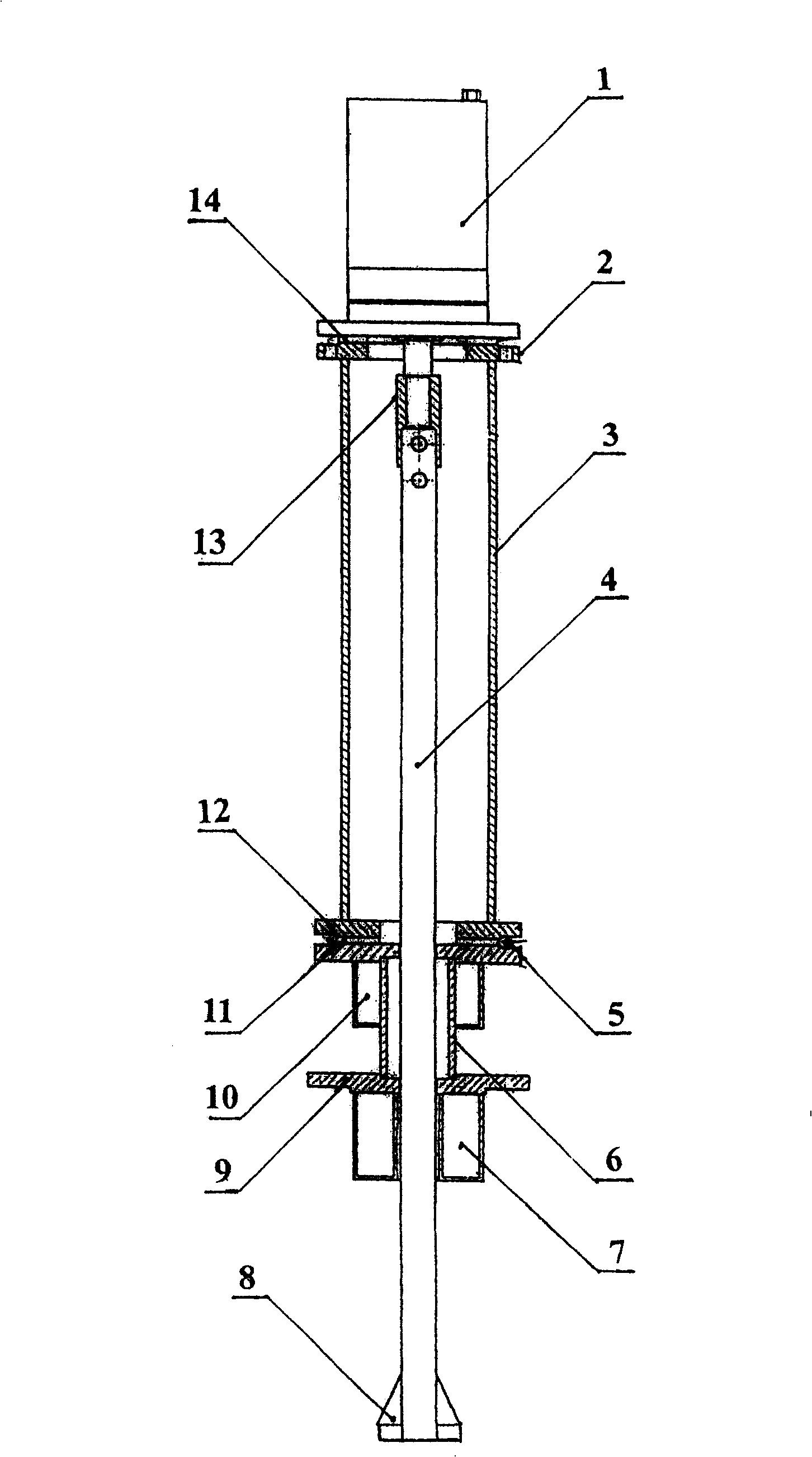

[0011] An example of the composition of the distillation channel clearer of the present invention includes a driving device 1, an upper flange 2, a cylinder body 3, a stopper rod 4, a lower rubber pad 5, a small cylinder body 6, a sealing sleeve 7, a scraper head 8, and a lower flange 9 , Cooling water jacket 10, small cylinder flange 11, cylinder flange 12, joint 13, rubber pad 14.

[0012] One end of the cylinder body 3 of the distillation channel clearer of the present invention is connected to the driving device 1 through the upper flange 2 , and the other end is connected to the small cylinder body 6 through the small cylinder flange 11 and the cylinder flange 12 . The outside of the small cylinder 6 is provided with a cooling water jacket 10, the lower end of which is connected to the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com