Rechet spanner

A ratchet wrench and wrench technology, applied in the field of wrenches, can solve the problems of insufficiency of operation, high production cost, large width of handle part, etc., and achieve the effects of simple and reasonable structure design, simple and convenient production and processing, and saving working time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

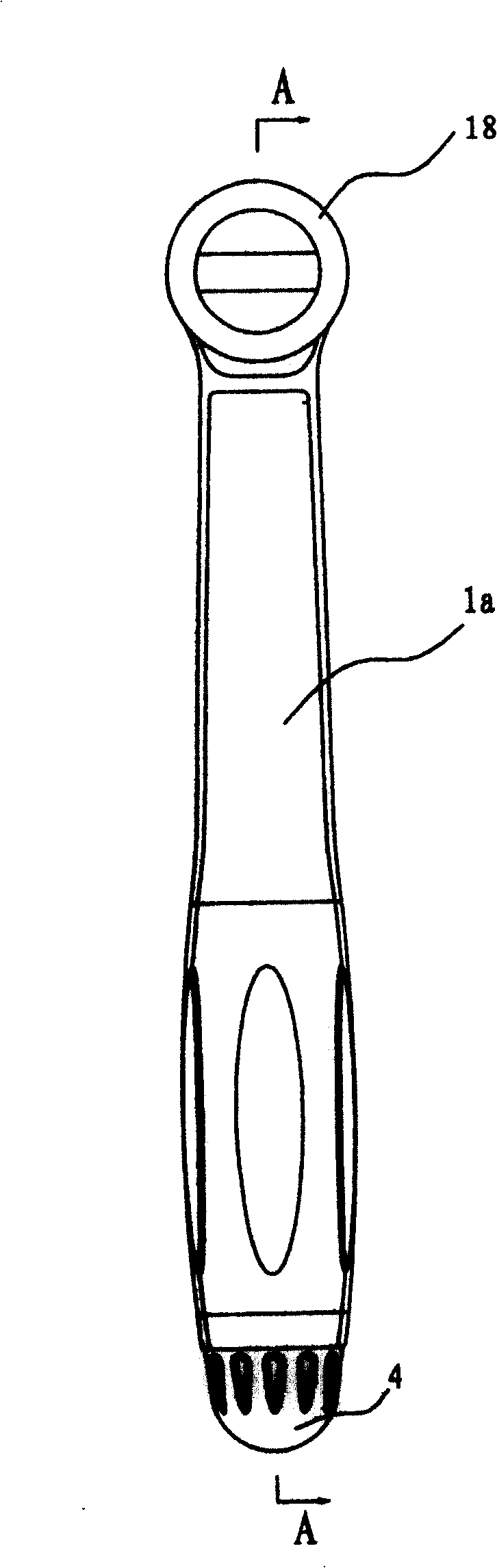

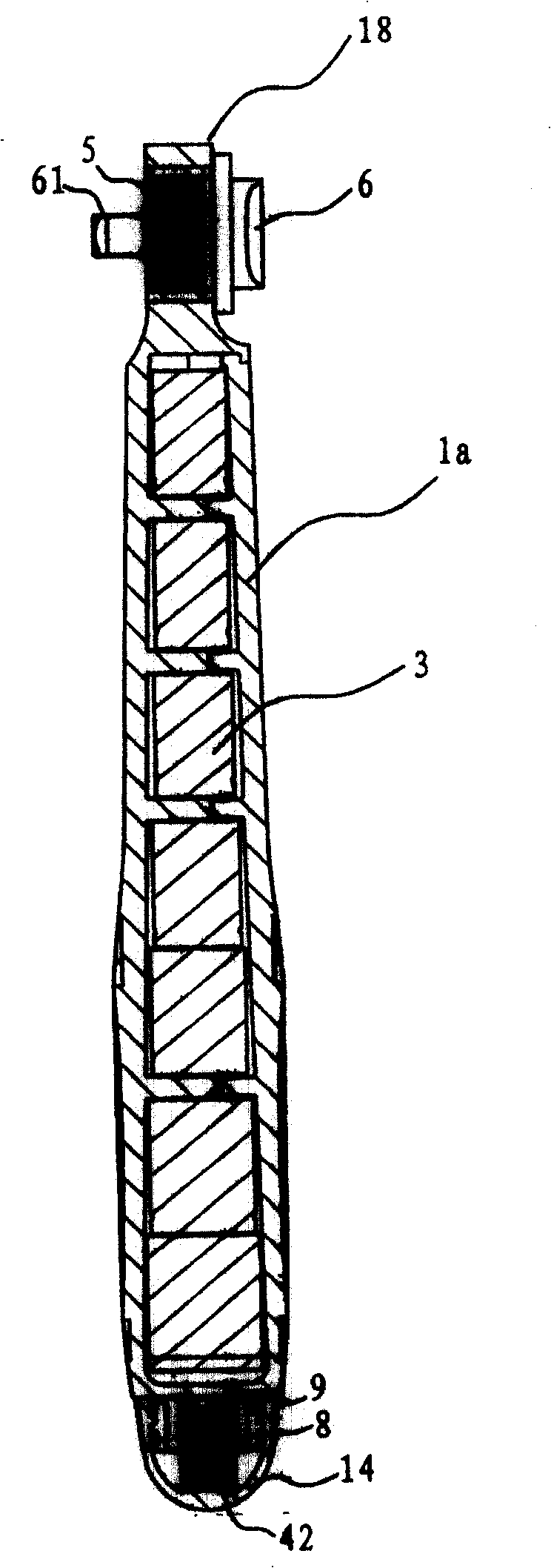

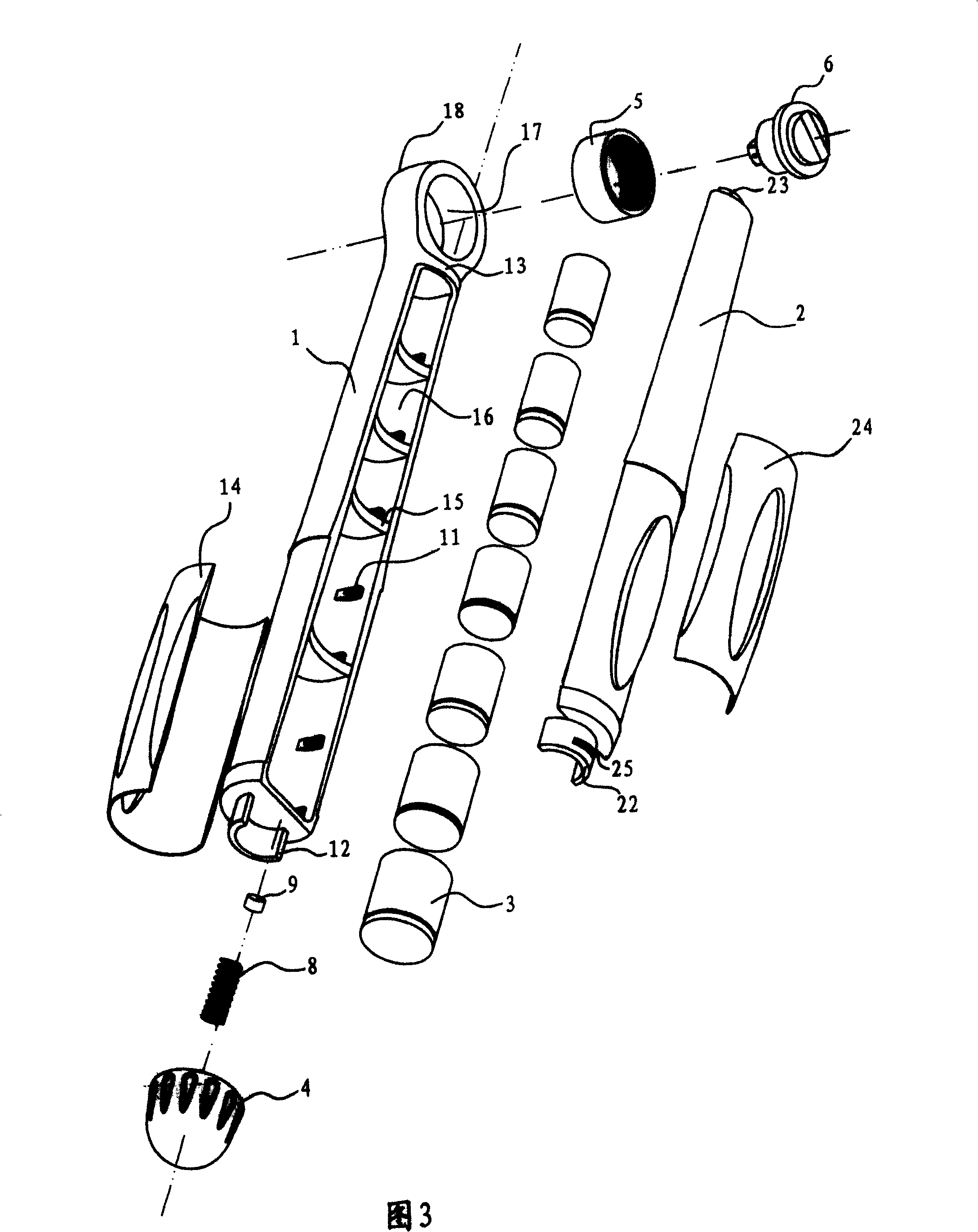

[0019] Example: Reference figure 1 , figure 2 and Figure 3.

[0020] The ratchet wrench in this embodiment includes a handle 1a and a detachable sleeve 3 disposed on the handle head 18. A cavity for placing seven sleeves 3 is arranged in the handle 1a. The handle 1a is composed of an upper cover 2 and an upper cover. 2. Composed of a detachable fitted lower cover 1, the sleeve 3 has a joint part where one end is combined with the handle head 18, and the other end has a concave matching part suitable for driving nuts, screws or bolts. A ratchet 5 and a driving body 6 are provided in the through hole 17 of the handle head 18 , and one end of the driving body 6 is provided with a driving part 61 that is connected and engaged with the coupling part of the sleeve 3 .

[0021] The detachable matching structure of the upper cover 2 and the lower cover 1 is as follows: the wrench also includes a rear cover 4 located at the end of the handle 1a, and the upper cover 2 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com