Rotor of multipole internal rotor permanent magnet generator

A permanent magnet generator and rotor-type technology, which is applied in the manufacture of stator/rotor bodies, magnetic circuits, electric components, etc., can solve problems such as miniaturization, light weight and thinning that are difficult to achieve, and achieve lower temperature and higher Efficiency, the effect of high permanent magnet utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

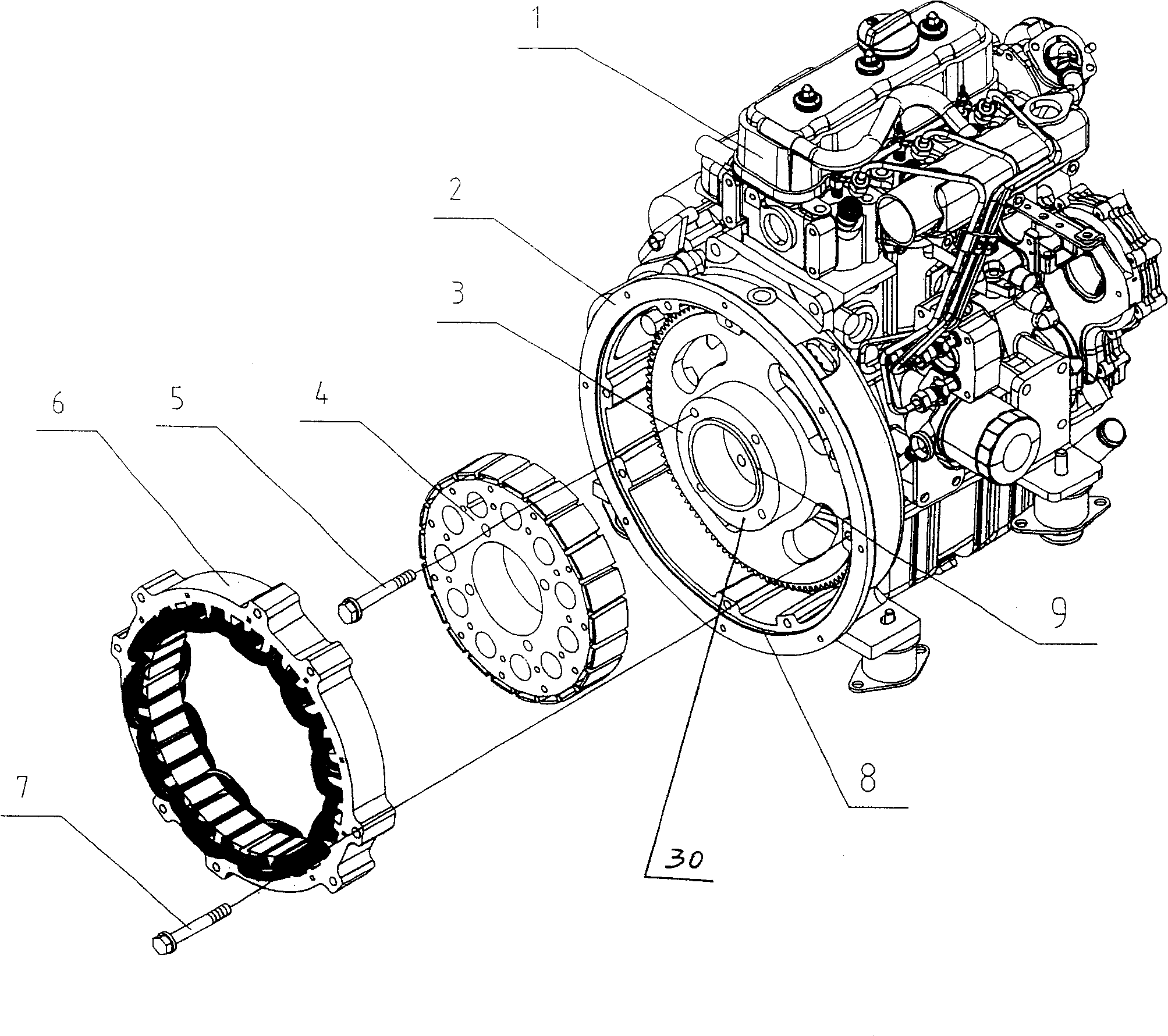

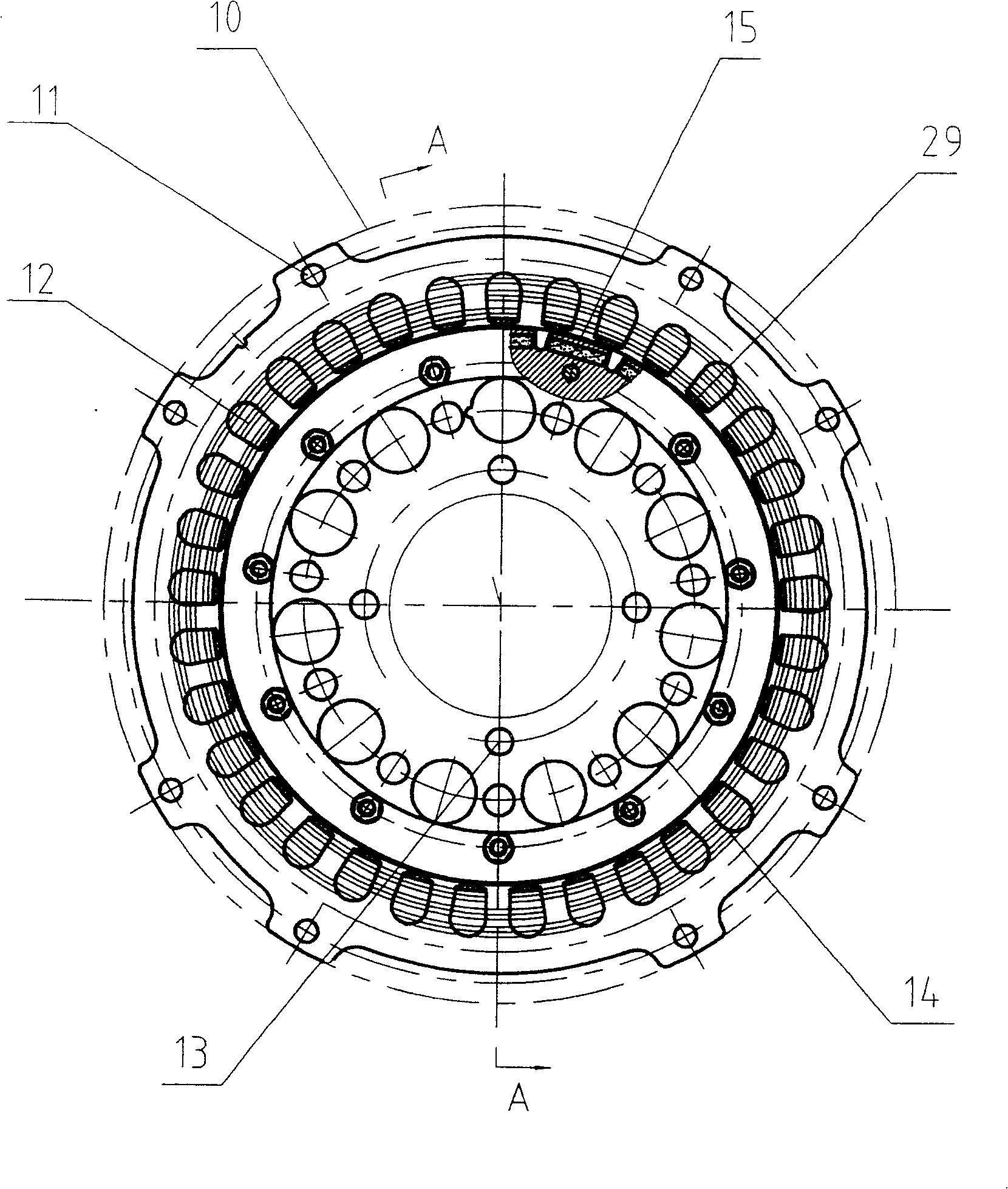

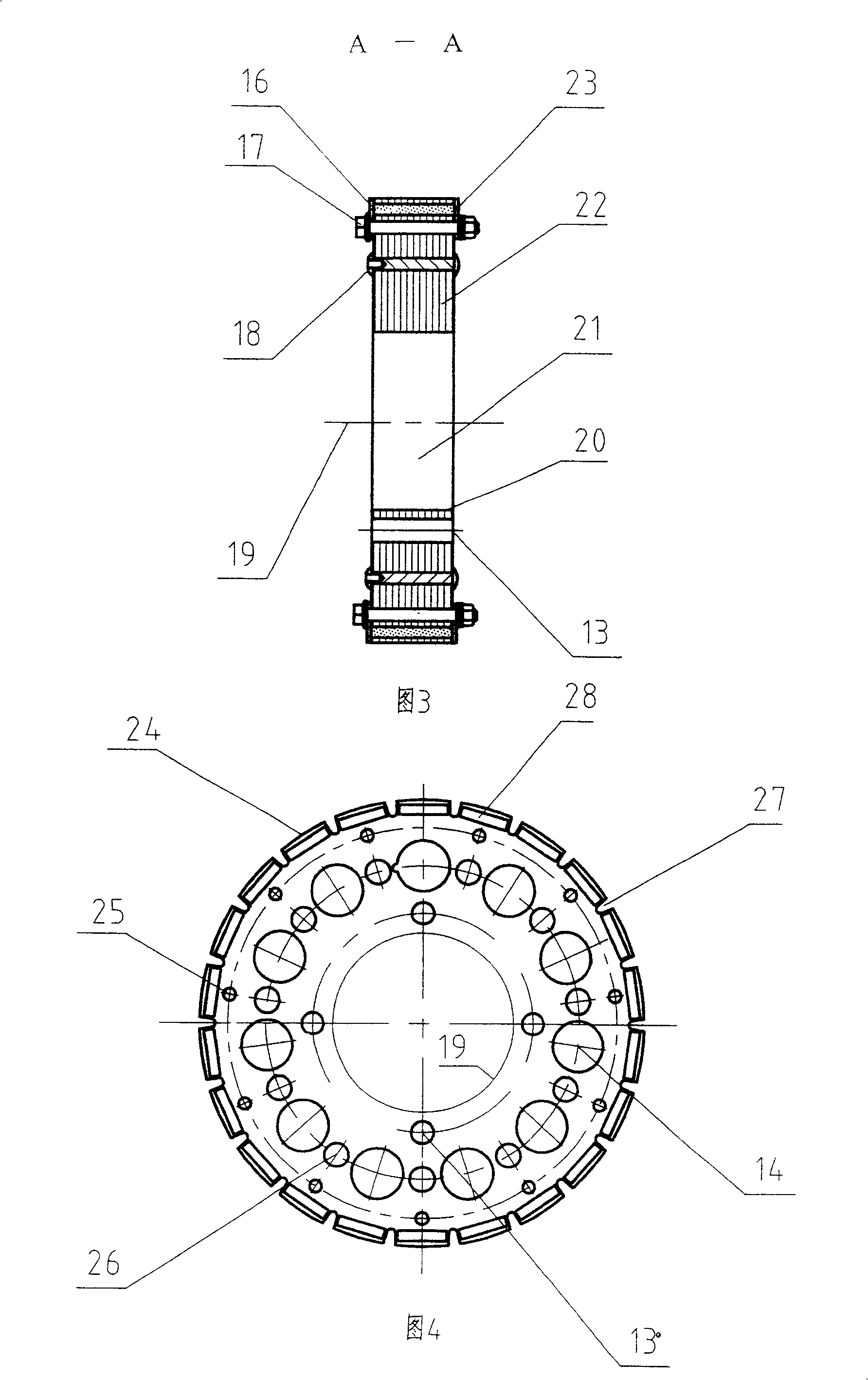

[0021] This embodiment is mainly composed of engine assembly 1, stator seat 2, rotor seat 3, rotor assembly 4, bolt 5, stator assembly 6, bolt 7, stator seat positioning opening 8, rotor seat positioning opening 9, stator positioning circle 10 , stator bolt holes 11, stator windings 12, rotor bolt holes 13, rotor cooling ventilation holes 14, permanent magnets 15, first permanent magnet baffle 16, baffle fixing bolts 17, rivets 18, rotor rotation center 19, positioning inside the rotor Circle 20, rotor body 21, rotor punching plate 22, second permanent magnet baffle plate 23, rotor body circle 24, baffle plate bolt hole 25, rivet hole 26, magnetic resistance groove 27, permanent magnet storage groove 28, insert piece 29 and The rotary body 30 of the engine etc. is composed.

[0022] figure 1 , figure 2 Shown: the rotor assembly 4 of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com