Cell diaphragm, its preparation method and zinc electrode secondary battery containing said diaphragm

A kind of separator and resistance technology, applied in the field of battery separator, its preparation and zinc electrode secondary battery containing the separator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The present invention provides a kind of preparation method for the separator of zinc electrode secondary battery, and it comprises the steps:

[0018] a) preparing a solution containing one or more grafting monomers;

[0019] b) performing irradiation grafting on the polymer microporous membrane base material in the solution to obtain a diaphragm;

[0020] c) drying the membrane.

[0021] a) Preparation of a solution containing one or more grafted monomers

[0022] In the method of the present invention, a solution containing one or more grafting monomers is first prepared. Applicable grafting monomers can be selected according to specific needs. For example, the grafting monomers of the present invention may be selected from C 2 ~C 10 Ethylenically unsaturated monomers, or polyoxyethylene ether oligomers containing phenolic groups and alkyl groups with a polymerization degree of less than 100.

[0023] The C 2 -C 10 Non-limiting examples of ethylenically unsat...

Embodiment 1

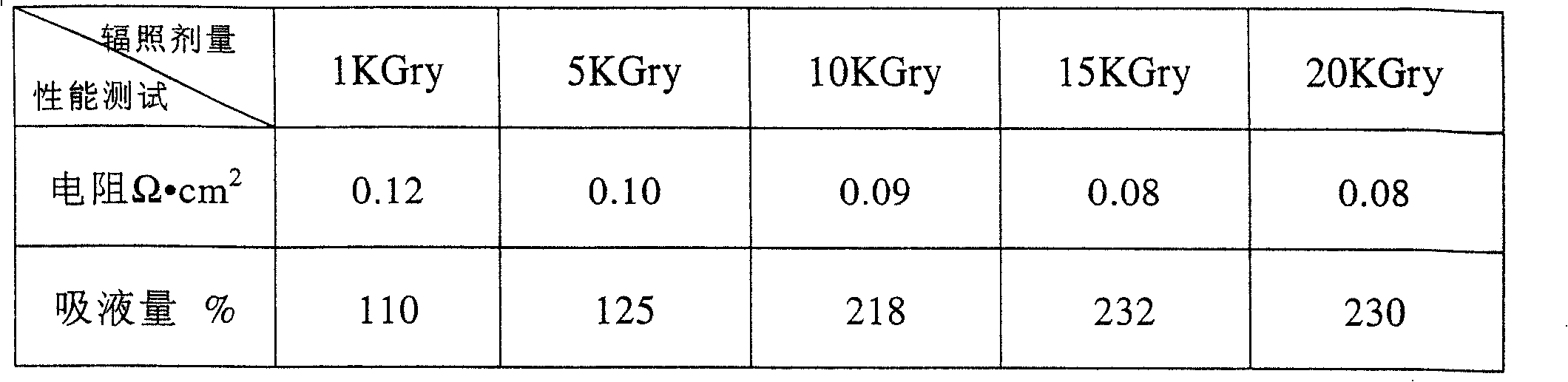

[0064] This example illustrates the effect of radiation dose on the final membrane produced.

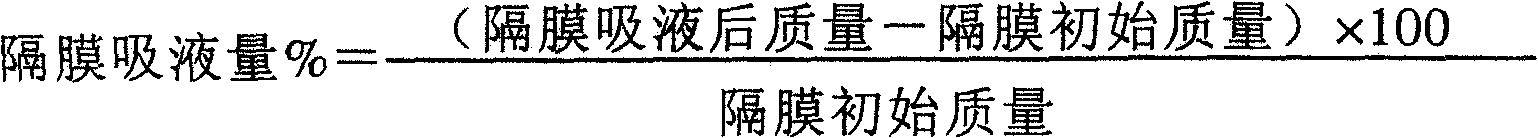

[0065] After the polypropylene microporous membrane substrate is irradiated in the grafting solution whose main component octylphenol polyoxyethylene ether content is 10% by weight (solvent is water), the dosage listed in the following table 1 is taken out, and through pickling After drying, the membrane was obtained. The electrical properties and hydrophilic properties of the separator were tested according to the test standards, and the results are listed in Table 1 below.

[0066] Table 1

[0067]

[0068] The test results show that the resistance of the diaphragm is lower than 0.15Ω·cm when the irradiation dose is in the range of 1-20KGry 2 , The liquid absorption is greater than 100%.

Embodiment 2

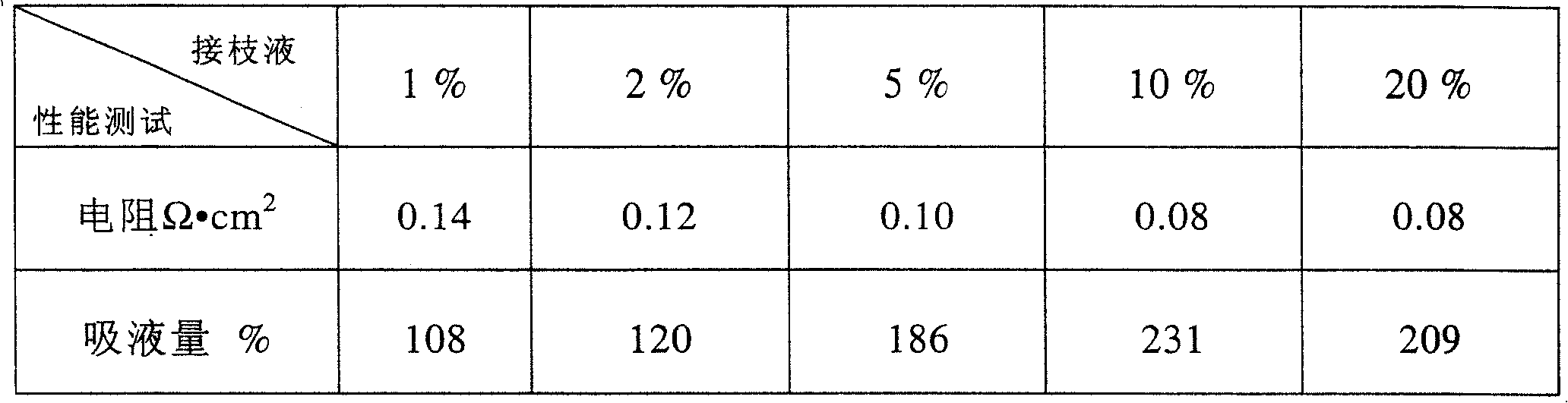

[0070] This example illustrates the situation of diaphragms prepared with different concentrations of grafting solutions.

[0071] After the polypropylene microporous membrane substrate is irradiated with the same dose (10KGry) in the grafting liquid (the solvent is water) of the main component nonylphenol polyoxyethylene ether mass percentage content listed in the following table 2, and after washing Dry to obtain a membrane. The electrical properties and hydrophilic properties of the separator were tested according to the test standards, and the results are listed in Table 2 below.

[0072] Table 2

[0073]

[0074] The test results show that the grafted monomer concentration is in the range of 2-20% (weight percentage), and the resistance of the diaphragm is lower than 0.15Ω·cm 2 , The liquid absorption is greater than 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com