Method for testing GaN single-crystal fault kind and density

A technology of defect types and detection methods, which is applied in the direction of measuring devices, semiconductor/solid-state device testing/measurement, and material analysis through optical means, which can solve the requirements of electrical conductivity, unfavorable averaging of a large number of observations, and the inability to determine the depth of corrosion pits and other issues to achieve the effect of wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

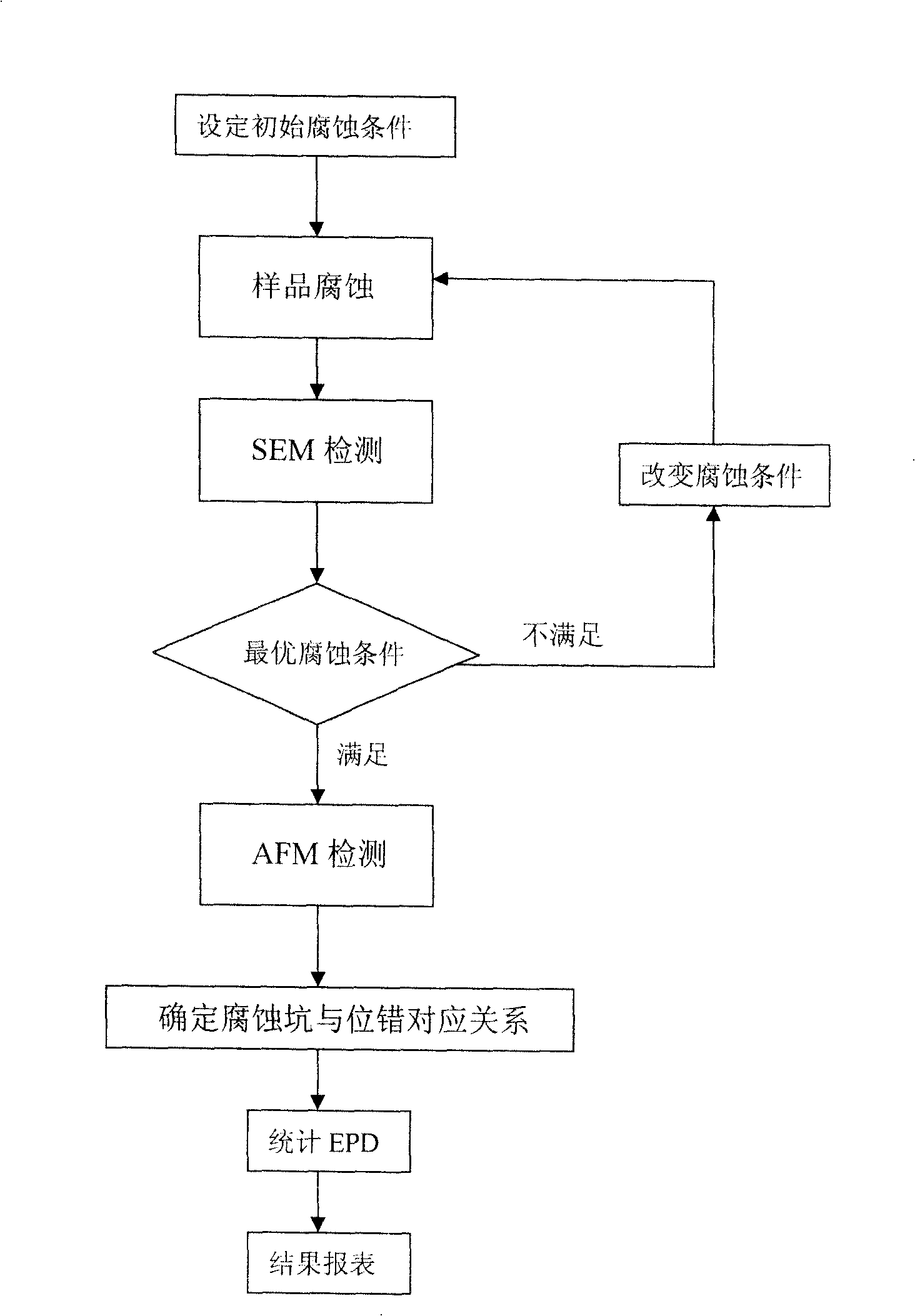

[0033] refer to figure 1 , which is a block flow diagram of the detection method of the present invention, from which the specific steps of the method can be clearly seen. Now combine specific steps and specific examples to illustrate its working process:

[0034] 1. Set the initial corrosion conditions. The initial corrosion temperature and time were estimated from the surface topography of the uncorroded sample.

[0035] 2. Sample corrosion. Clean and remove the organic contamination on the surface of the GaN sample, preheat the crucible to remove the water in it, add KOH particles to heat to the set temperature, put the sample and time it, take out the sample and clean it after the set time. The residual potassium hydroxide is discharged after treatment, and the crucible is cleaned for the next use.

[0036] 3. Carry out SEM detection. On the corroded sample, select nine positions on a wafer or semi-circle, and select more than 3 microscopic areas near each position to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com