Panel display having integrated back grid structure and its manufacturing technology

A flat panel display and back grid technology, which is applied in the manufacture of discharge tubes/lamps, image/graphic display tubes, and cold cathode manufacturing, etc., can solve the problem of relatively high device material requirements, carbon nanotube cathode pollution, and high gate control voltage. problems, to achieve the effect of improving luminous efficiency, improving field emission efficiency, and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to these embodiments.

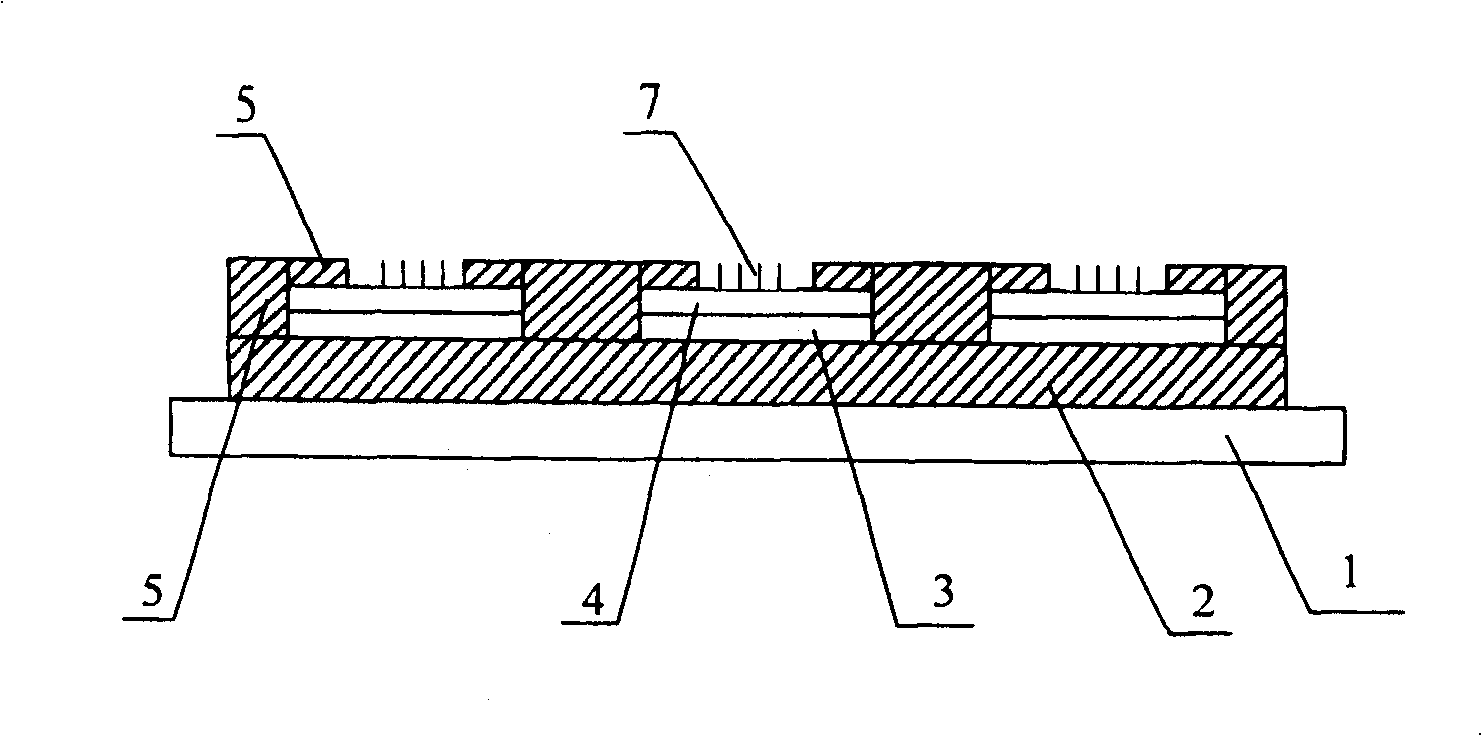

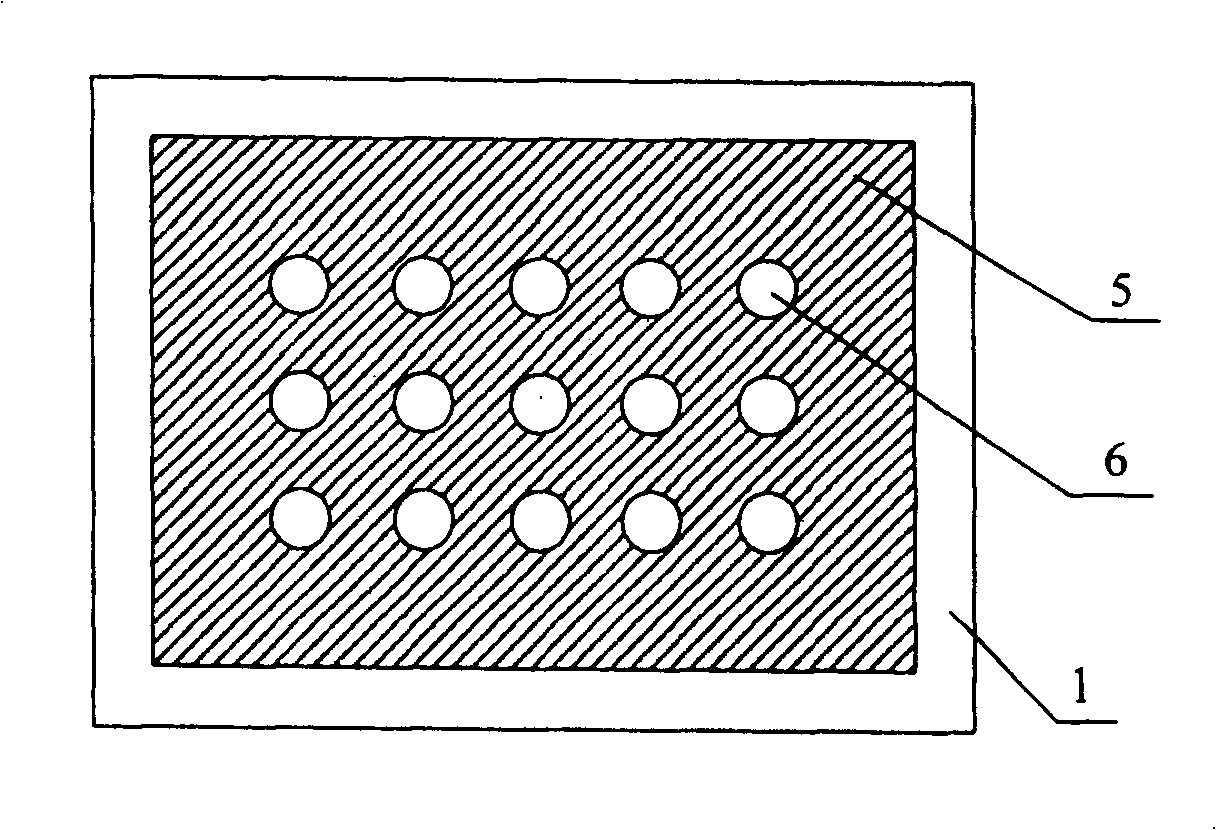

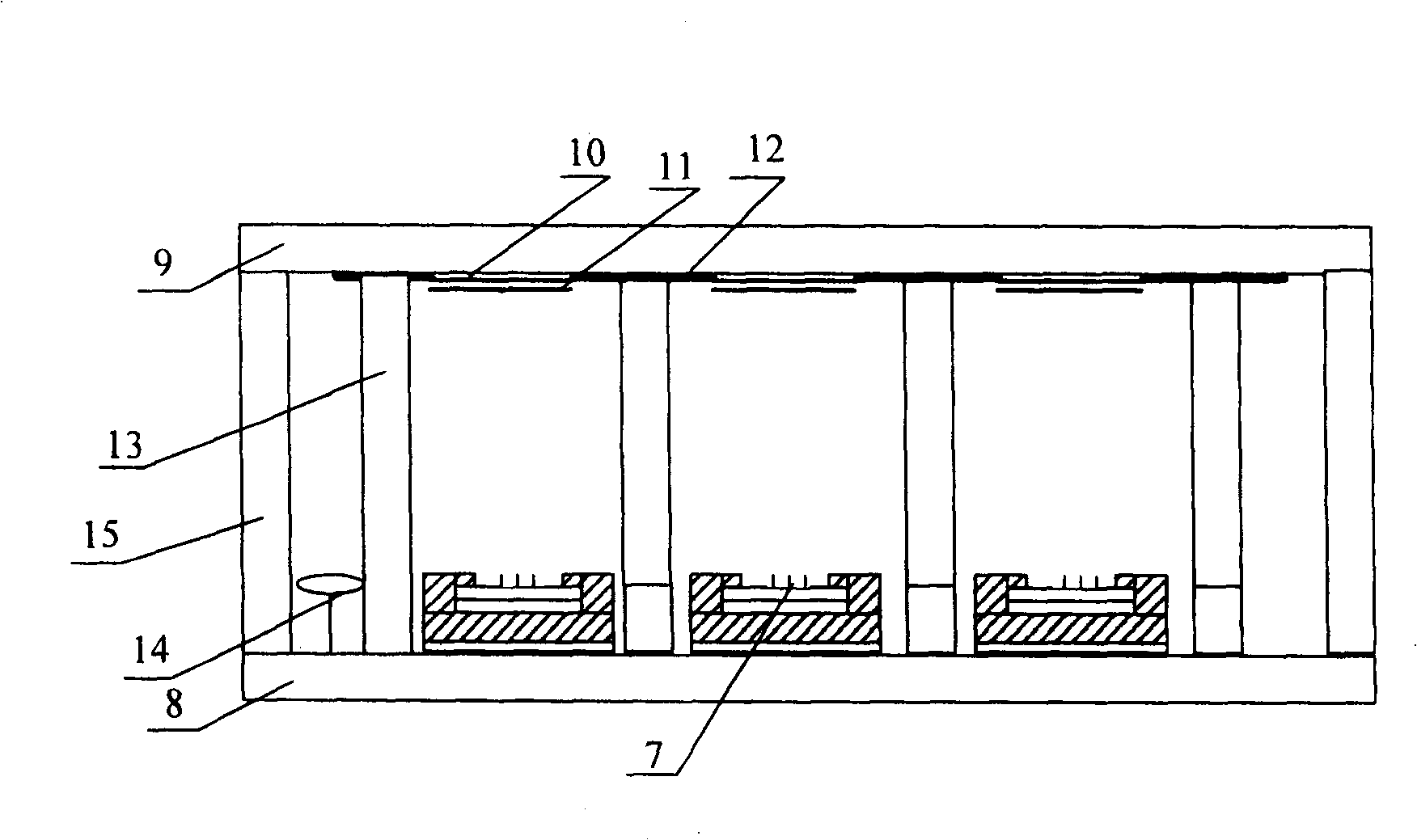

[0042] The present invention comprises a sealed vacuum chamber composed of a cathode panel 8, an anode panel 9 and surrounding glass frames 15; an anode conductive strip 10 and a phosphor layer 11 prepared on the anode conductive strip 10 are arranged on the anode panel 9; The support wall structure 13 between the cathode panel 8 and the anode panel 9 and the getter accessory element 14 are fabricated on the cathode panel 8 with an integrated back grid structure containing the carbon nanotube cathode 7 and controlling the electron emission of the carbon nanotube cathode. The integrated back gate structure includes the base material silicon wafer 1, the first silicon dioxide layer 2 fabricated on the base material silicon wafer 1, and each metal transition formed by photolithography on the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com